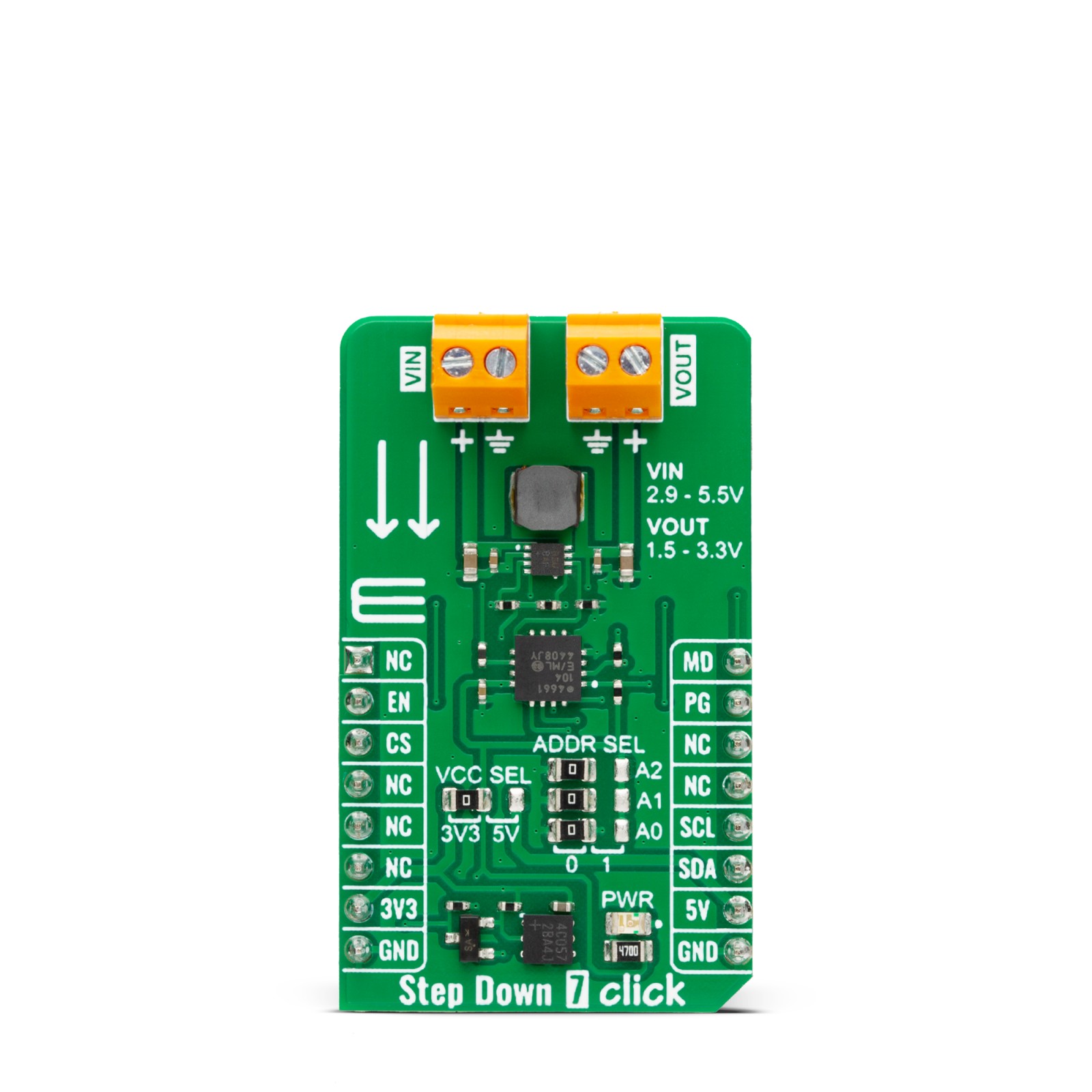

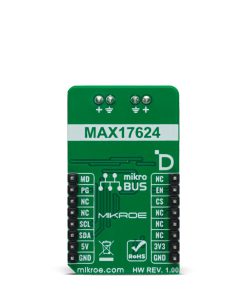

Step Down 7 Click

R315.00 ex. VAT

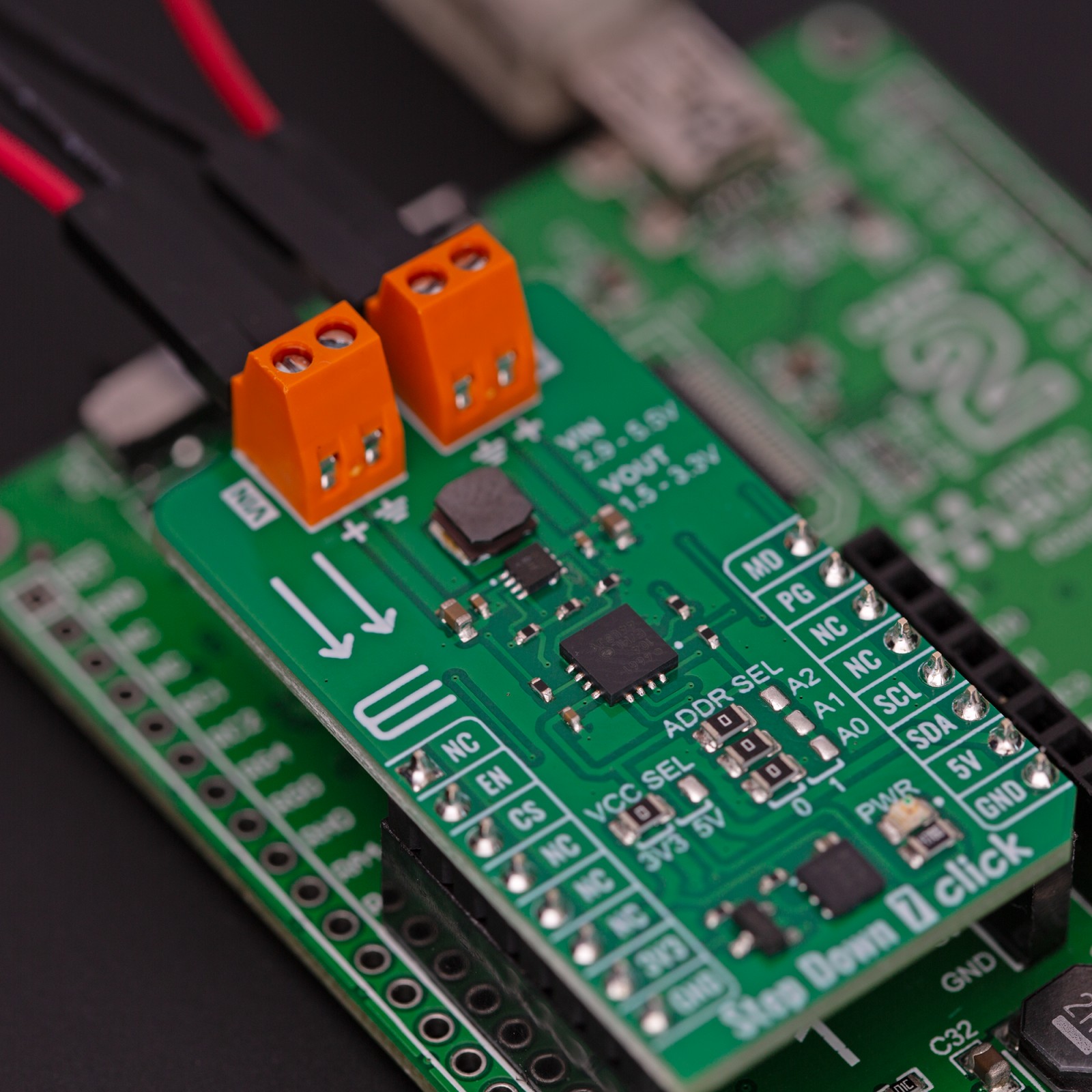

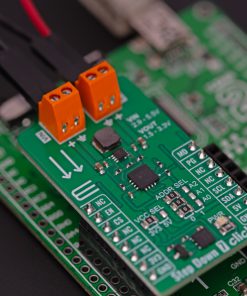

Step Down 7 Click is a compact add-on board that converts higher voltages into a lower voltages level. This board features the MAX17624, a synchronous step-down converter with integrated MOSFETs from Analog Devices. The converter, as input, uses voltages in the range from 2.9V up to 5.5V and can output step-down voltages from 1.5V to 3.3V up to 1A. It features high efficiency, and depending on the mode of operation, it works at a fixed 4MHz switching frequency. In addition, it comes with undervoltage lockout, overcurrent protection, and thermal overload protection. This Click board™ makes the perfect solution for the development of power conversion solutions in automation and control applications, industrial sensors, test and measurement equipment, portable low-power devices, and more.

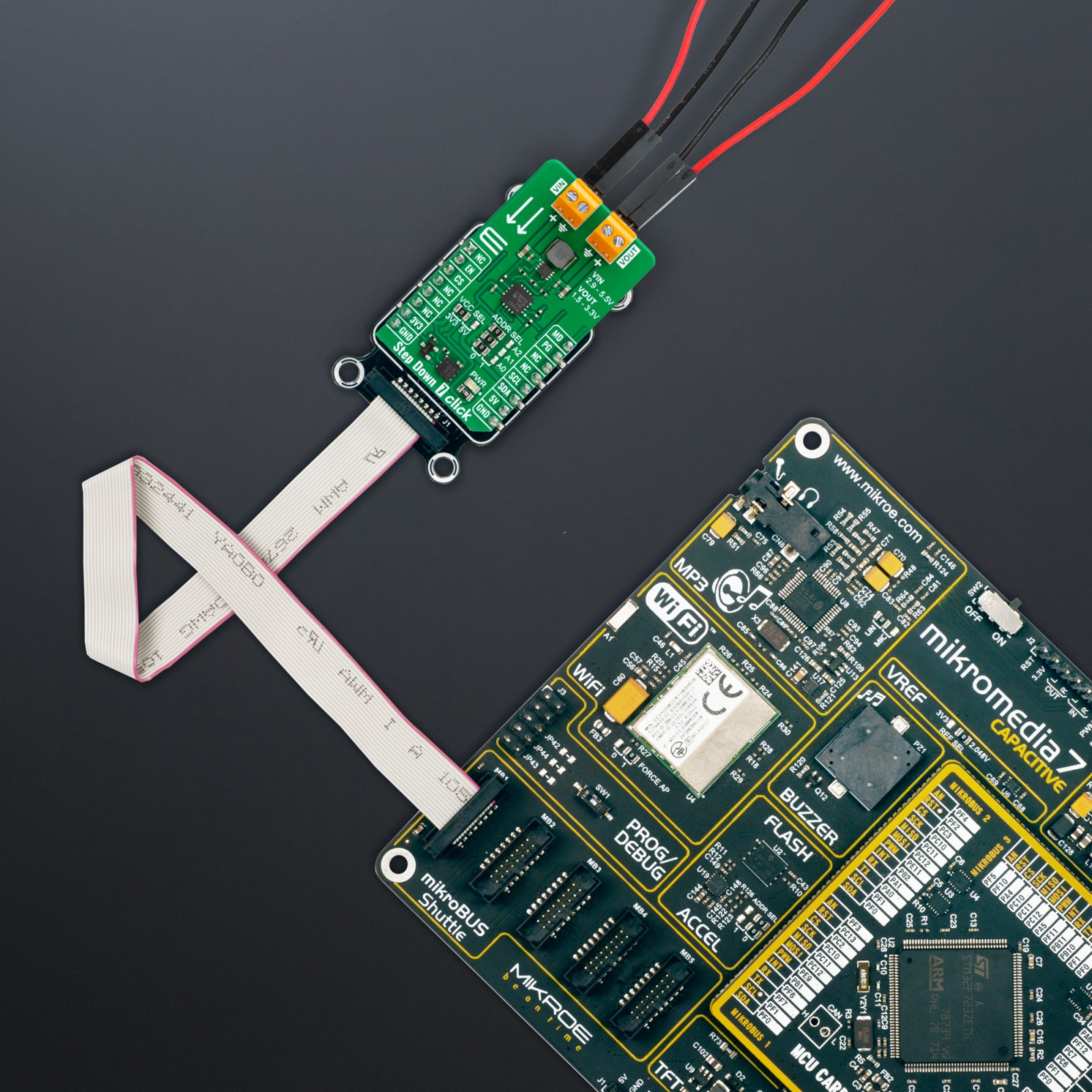

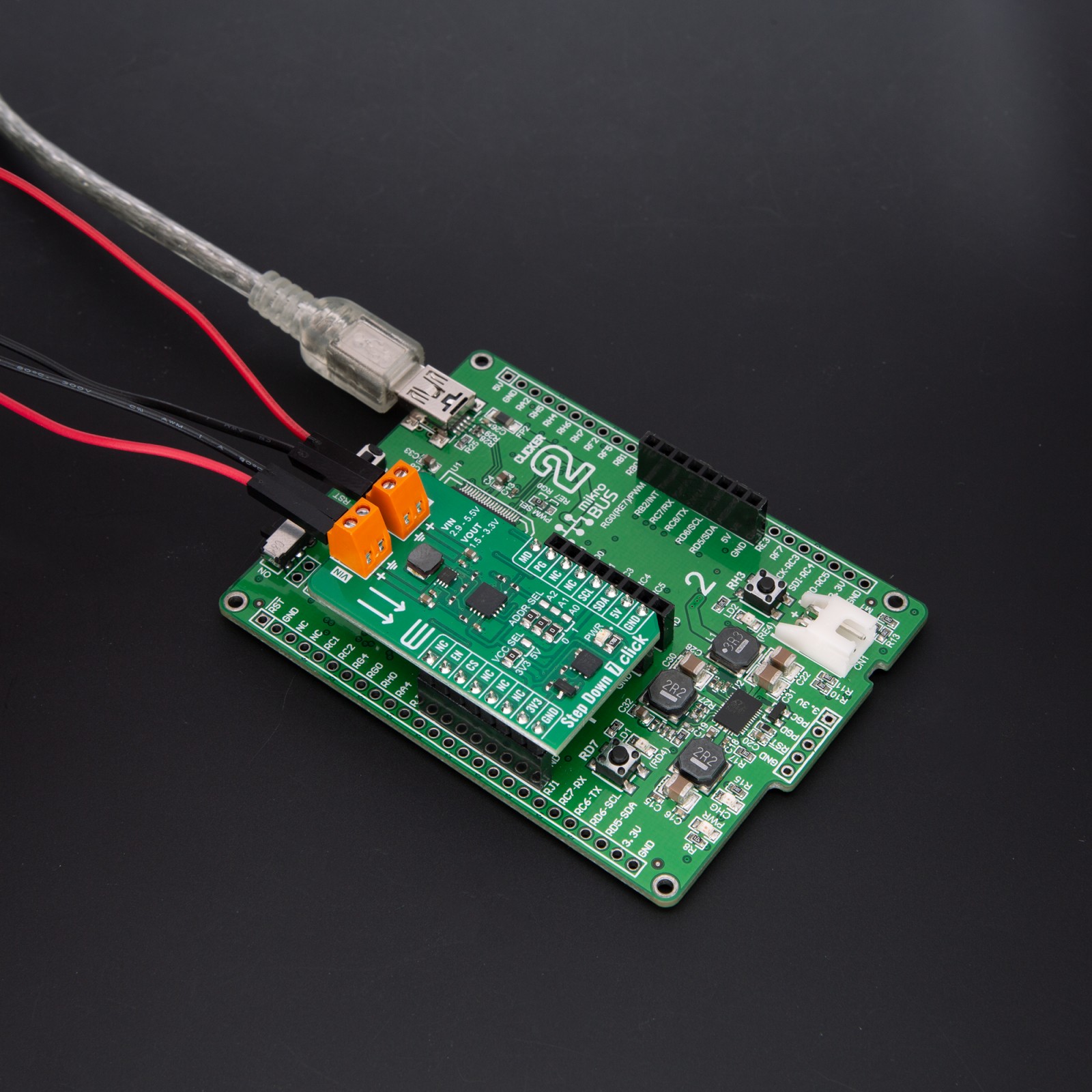

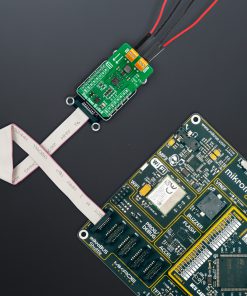

Step Down 7 Click is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. What sets this Click board™ apart is the groundbreaking ClickID feature, enabling your host system to seamlessly and automatically detect and identify this add-on board.

Stock: Lead-time applicable.

| 5+ | R299.25 |

| 10+ | R283.50 |

| 15+ | R267.75 |

| 20+ | R257.67 |

.jpg)