Stepper 13 Click

R320.00 ex. VAT

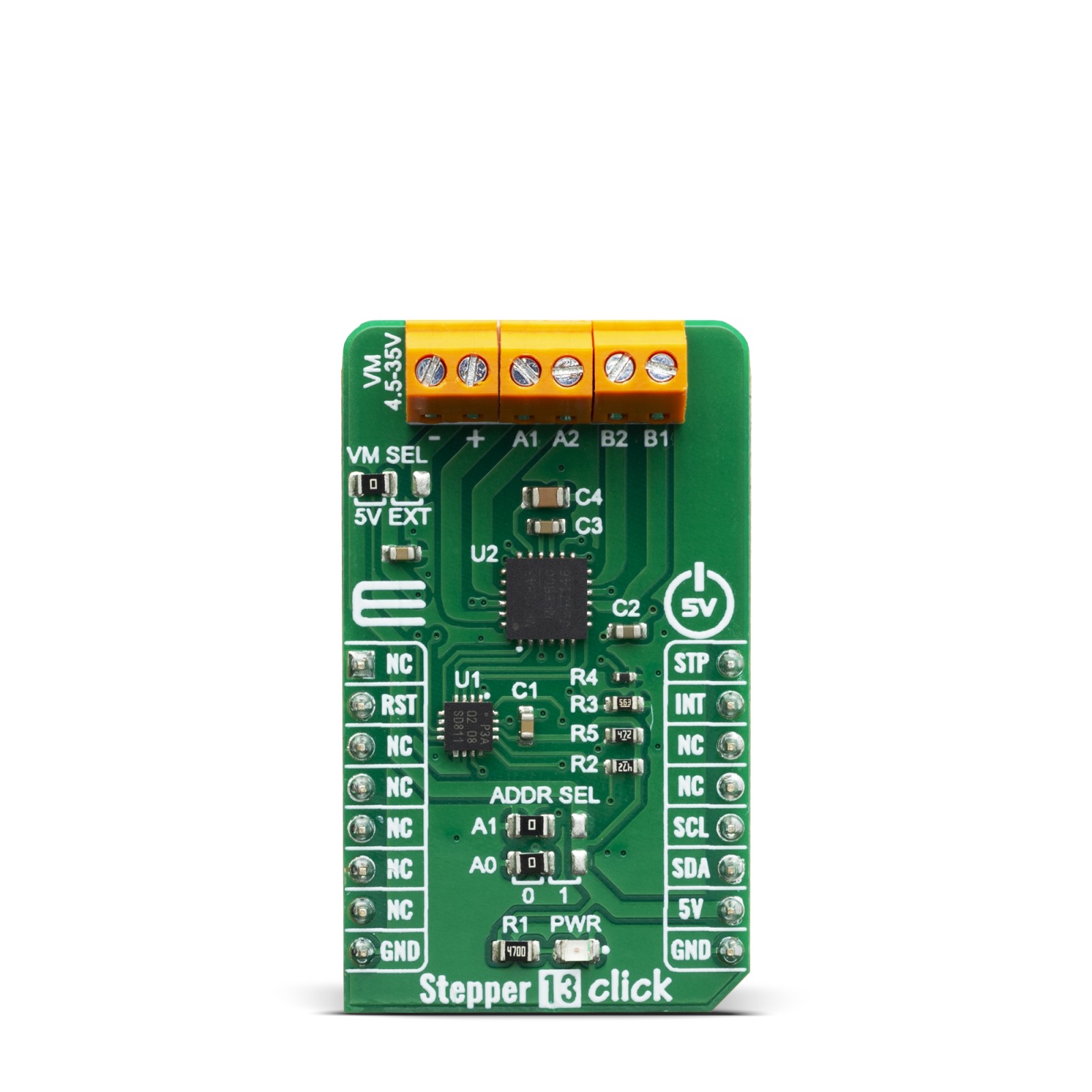

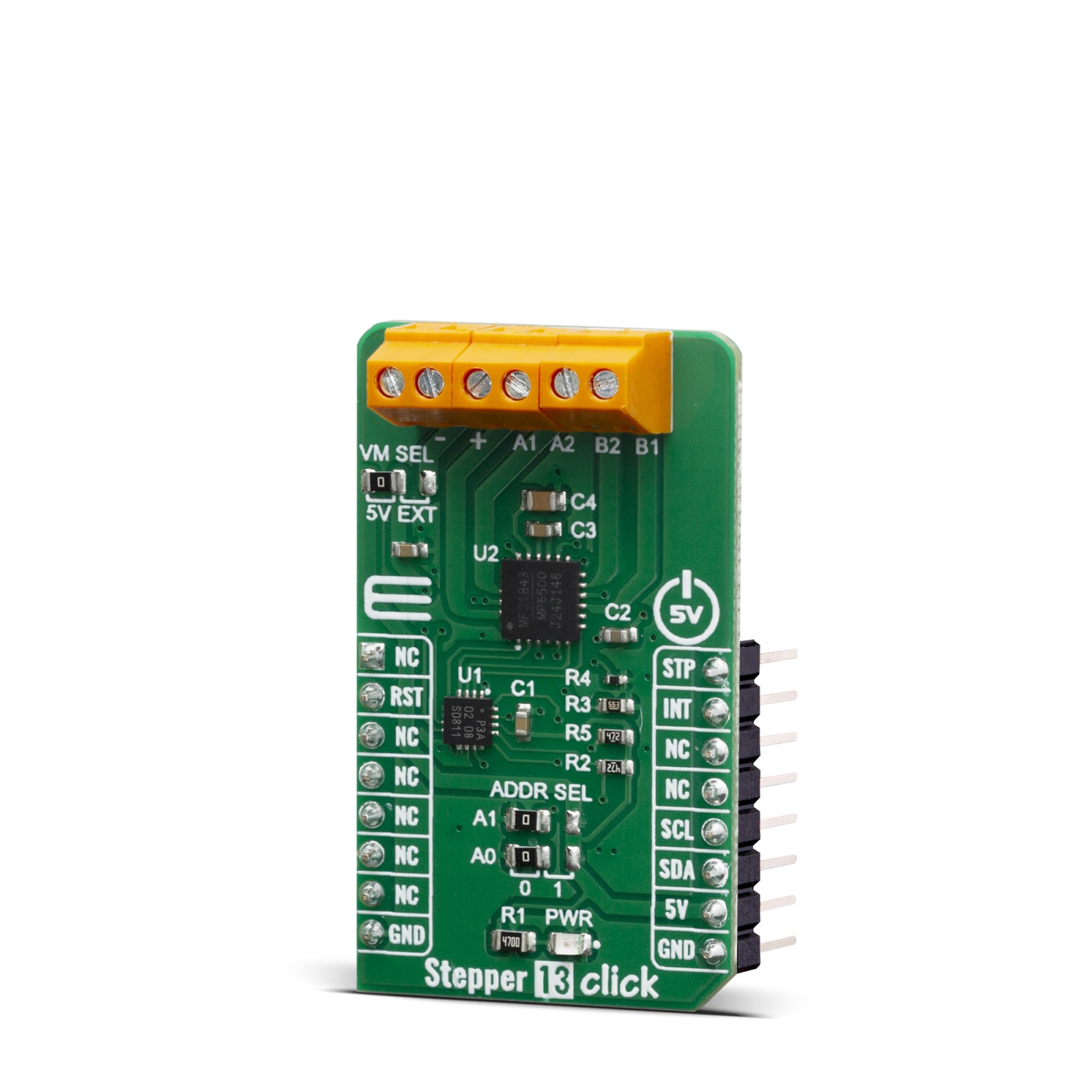

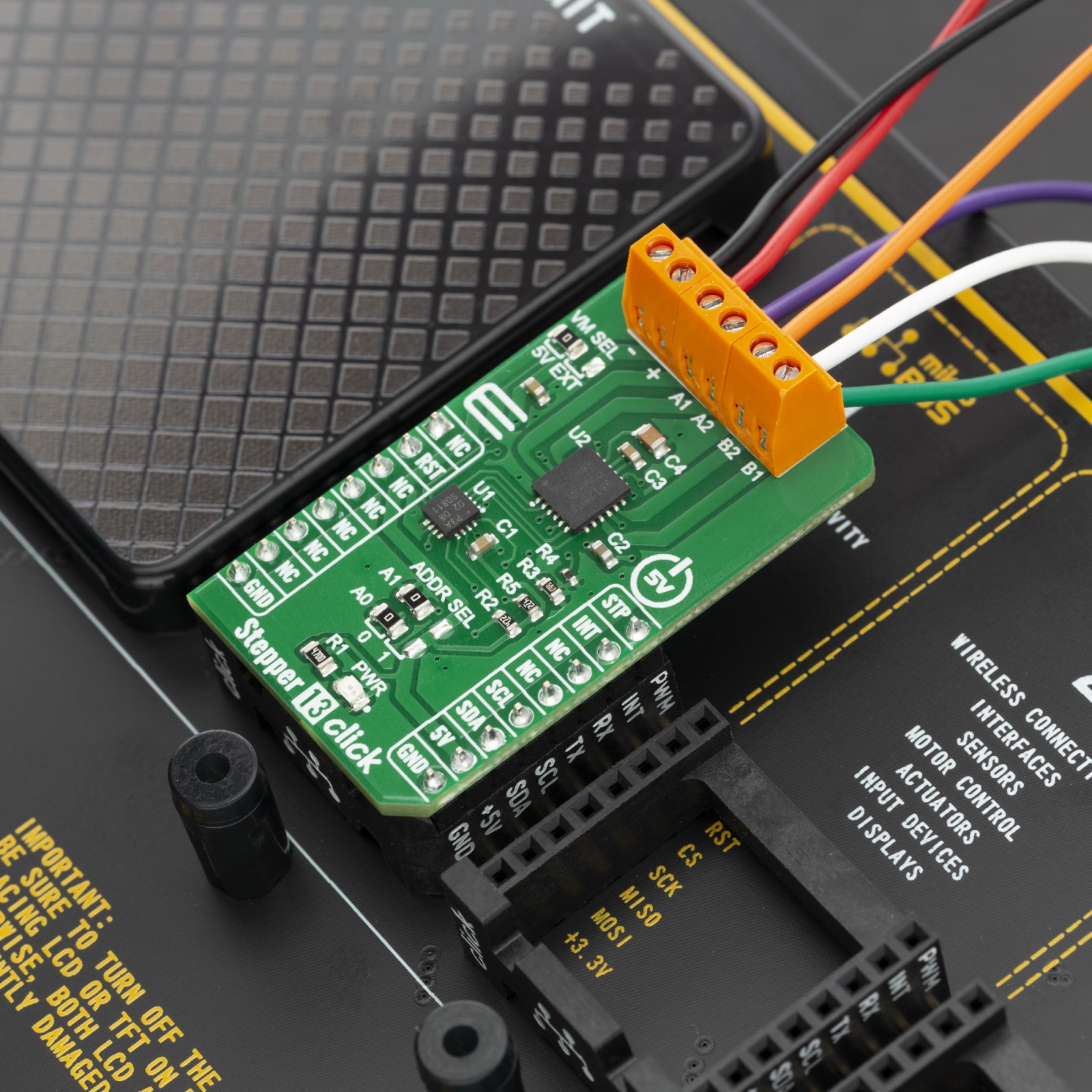

Stepper 13 Click is a bipolar step motor driver. It features an H-bridge bipolar step motor driver, which supports full-, half-, quarter-, or eighth-step modes. Stepper 13 click also carries a port expander so that the communication can be done with a minimal number of pins, through the mikroBUS™ I2C bus. This click board™ offers thermal protection, integrated kickback voltage protection, it has a wide range of input voltage, protection against current shoot-through the H-Bridge and high current capability. These features make Stepper 13 click an ideal solution for driving motors in any application that demands a precise and safe step motor driver.

Stepper 13 click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R304.00 |

| 10+ | R288.00 |

| 15+ | R272.00 |

| 20+ | R261.76 |

Stepper 13 click operates from a supply voltage of up to 35V and can deliver motor currents up to 2.5A (depending on use case and thermal conditions). It also can operate a bipolar stepper motor in full-, half-, quarter-, or eighth-step modes. Thanks to internal safety features, such as over-current protection (OCP), input over-voltage protection (OVP), under-voltage lockout (UVLO), and thermal shutdown, this click board™ is perfectly suited for rapid development of various stepper motor applications, including ATM-related applications, toys, 3D printers, mechatronics, robotics-related applications, etc.

How does it work?

This click board™ is equipped with two integrated circuits. The step motor driver IC is the MP6500, a dual full-bridge motor driver from MPS. This IC internal structure is somewhat symmetrical. It features two MOSFET H-bridges used to drive two coils of a bipolar step motor in both directions. The MP6500 uses a wide input voltage range – from 4.5V to 35V. This is the voltage used to energize the motor coils. A jumper (JP3) is used to select whether to use external power supply or to obtain the power supply from the mikroBUS™ +5V rail. The MP6500 has two PHASE inputs which are used to control the direction of current flow through H-bridges and thus, the motor coils. It also allows controlling step motor in both full step and half step modes, by toggling states on MS1 and MS1 pins.

.jpg)

The bipolar step motor coils can be connected to the onboard screw terminals. There are two terminals, used to connect each of the step motor coils. The third connector is used to connect an external voltage, ranging from 4.5V to 35V, depending on the used motor voltage requirements. It should be noted that without a valid external voltage connected to this terminal, the motor will not work. Also, it should be noted that 40V is an absolute maximum voltage allowed as per datasheet, thus the overtemperature protection might be activated when driving heavier loads. The recommended maximum voltage should not exceed 35V, as stated on the silkscreen layer of the PCB.

All of the MP6500 control lines are routed to the second IC on Stepper 13 board, which is the PCA9538A, a well-known 8bit I/O expander with a serial interface, used on many of the MikroElektronika’s designs for its simplicity and reliability. It allows the control lines of the MP6500 IC to be driven via the I2C and few pins it uses – reducing the required pin count of the Stepper 13 click. This also allows for sending compact I2C messages, instead of toggling several pins at once – which can introduce problems with timing sometimes, especially when those pins belong to different MCU ports. By changing states of the six control pins, it is possible to drive the step motor in full step mode as well as the half step mode. However, provided MikroElektronika libraries contain simple and intuitive functions to fully control the bipolar step motor, connected to Stepper 13 click. Their usage is demonstrated in the included example application, which can be used as a reference for a custom design.

The motor power supply can be connected to the input terminal labeled as VIN and should be within the range of 4.5V to 35V. Stepper motor coils can be connected to the terminals labeled as A1, B2, B1, and A2. The Click board™ supports an optional external power supply for the motor in order to work. However, it also requires 3.3V from the mikroBUS™ rail.

Specifications

Type

Stepper

Applications

Various stepper motor applications, including ATM-related applications, toys, 3D printers, mechatronics, robotics-related applications, etc.

On-board modules

MP6500 Dual Full-Bridge 35V, 2.5A, Stepper Motor Driver, from MPS; PCA9538A 8bit I/O Expander with Serial Interface, from NXP

Key Features

Thermal protection, integrated kickback voltage protection, it has a wide range of input voltage, protection against current shoot-through the H-Bridge and high current capability

Interface

GPIO,I2C

Feature

No ClickID

Compatibility

mikroBUS™

Click board size

M (42.9 x 25.4 mm)

Input Voltage

5V

Pinout diagram

This table shows how the pinout on Stepper 13 click corresponds to the pinout on the mikroBUS™ socket (the latter shown in the two middle columns).

Onboard settings and indicators

| Label | Name | Default | Description |

|---|---|---|---|

| LD1 | PWR | – | Power LED Indicator |

| JP1 | VM | Left | Power select jumper for port expander: left position 5V, right EXT |

| TB1 | Screw terminal | – | Terminal used for connecting the first coil of the step motor |

| TB2 | Screw terminal | – | Terminal used for connecting the external input voltage |

| TB3 | Screw terminal | – | Terminal used for connecting the second coil of the step motor |

Stepper 13 click electrical specifications

| Description | Min | Typ | Max | Unit |

|---|---|---|---|---|

| Receiver inputs voltage range | 4.5 | – | +35 | V |

| Receiver inputs current range | – | – | 2.5 | A |

Software Support

We provide a library for the Stepper 13 Click as well as a demo application (example), developed using MIKROE compilers. The demo can run on all the main MIKROE development boards.

Package can be downloaded/installed directly from NECTO Studio Package Manager (recommended), downloaded from our LibStock™ or found on MIKROE github account.

Library Description

This library contains API for Stepper 13 Click driver.

Key functions

-

stepper13_set_directionThis function sets the motor direction by setting the DIR pin logic state. -

stepper13_set_step_modeThis function sets the step mode resolution settings. -

stepper13_drive_motorThis function drives the motor for the specific number of steps at the selected speed.

Example Description

This example demonstrates the use of the Stepper 13 Click by driving the motor in both directions for a desired number of steps.

void application_task ( void )

{

log_printf ( &logger, " Move 200 full steps clockwise, speed: slowrnn" );

stepper13_set_direction ( &stepper13, STEPPER13_DIR_CW );

stepper13_set_step_mode ( &stepper13, STEPPER13_MODE_FULL_STEP );

stepper13_drive_motor ( &stepper13, 200, STEPPER13_SPEED_SLOW );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

log_printf ( &logger, " Move 200 half steps counter-clockwise, speed: mediumrnn" );

stepper13_set_direction ( &stepper13, STEPPER13_DIR_CCW );

stepper13_set_step_mode ( &stepper13, STEPPER13_MODE_HALF_STEP );

stepper13_drive_motor ( &stepper13, 200, STEPPER13_SPEED_MEDIUM );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

log_printf ( &logger, " Move 400 quarter steps counter-clockwise, speed: fastrnn" );

stepper13_set_direction ( &stepper13, STEPPER13_DIR_CCW );

stepper13_set_step_mode ( &stepper13, STEPPER13_MODE_QUARTER_STEP );

stepper13_drive_motor ( &stepper13, 400, STEPPER13_SPEED_FAST );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

The full application code, and ready to use projects can be installed directly from NECTO Studio Package Manager (recommended), downloaded from our LibStock™ or found on MIKROE github account.

Other MIKROE Libraries used in the example:

- MikroSDK.Board

- MikroSDK.Log

- Click.Stepper13

Additional notes and informations

Depending on the development board you are using, you may need USB UART click, USB UART 2 Click or RS232 Click to connect to your PC, for development systems with no UART to USB interface available on the board. UART terminal is available in all MIKROE compilers.

mikroSDK

This Click board™ is supported with mikroSDK – MIKROE Software Development Kit. To ensure proper operation of mikroSDK compliant Click board™ demo applications, mikroSDK should be downloaded from the LibStock and installed for the compiler you are using.

For more information about mikroSDK, visit the official page.

Resources

Downloads

| Weight | 19 g |

|---|---|

| Brand | MikroElektronika |