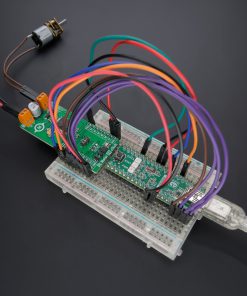

DC Motor 24 Click

R465.00 ex. VAT

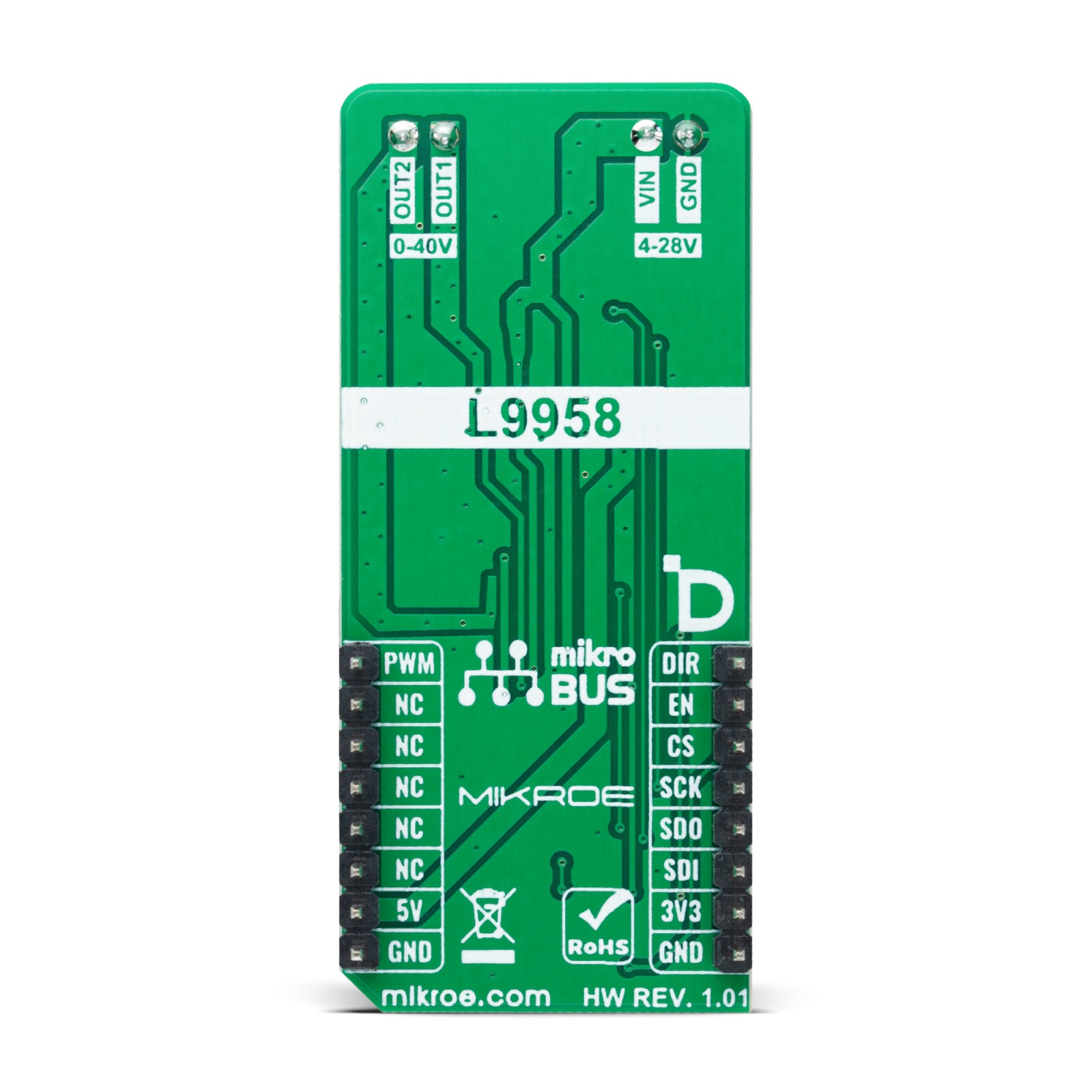

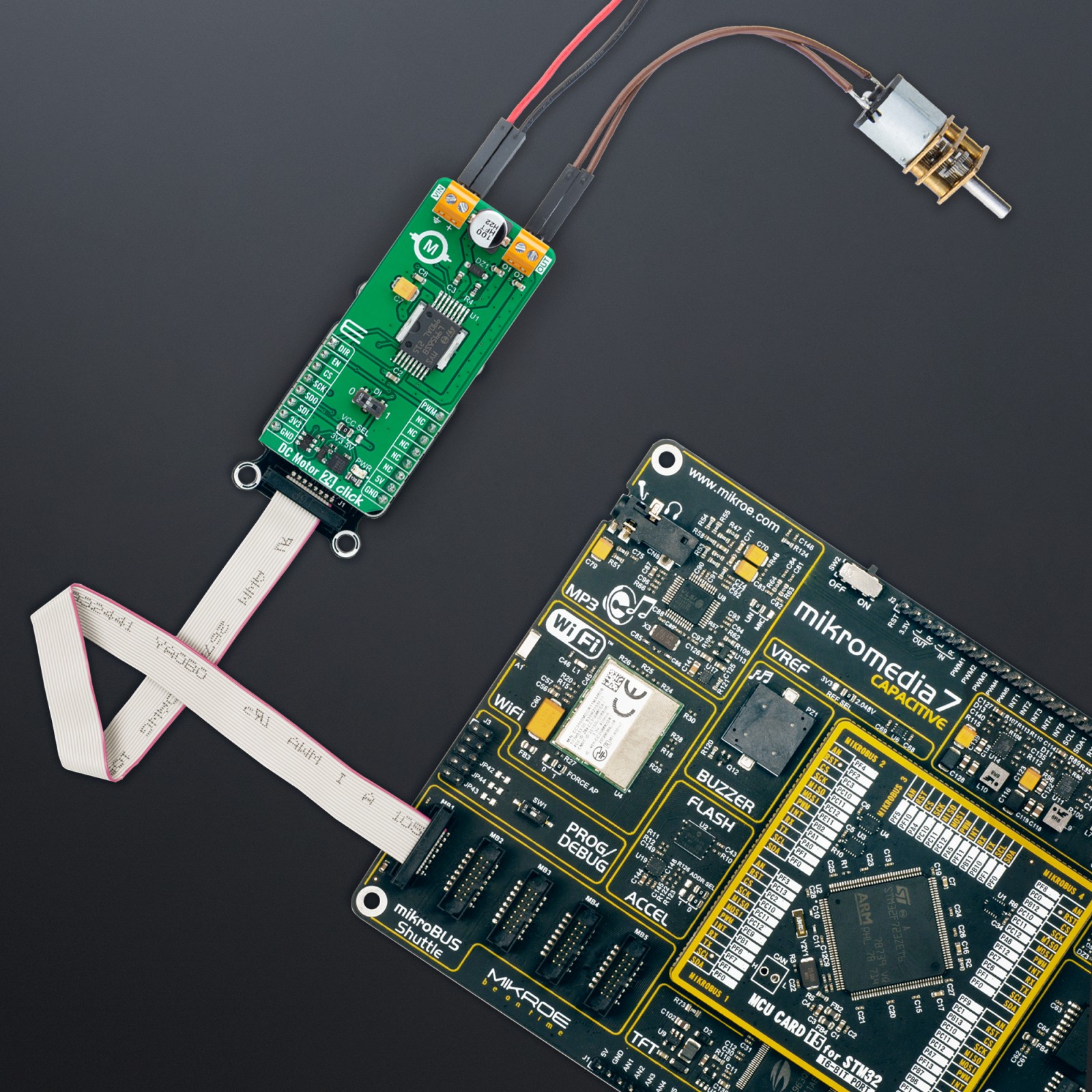

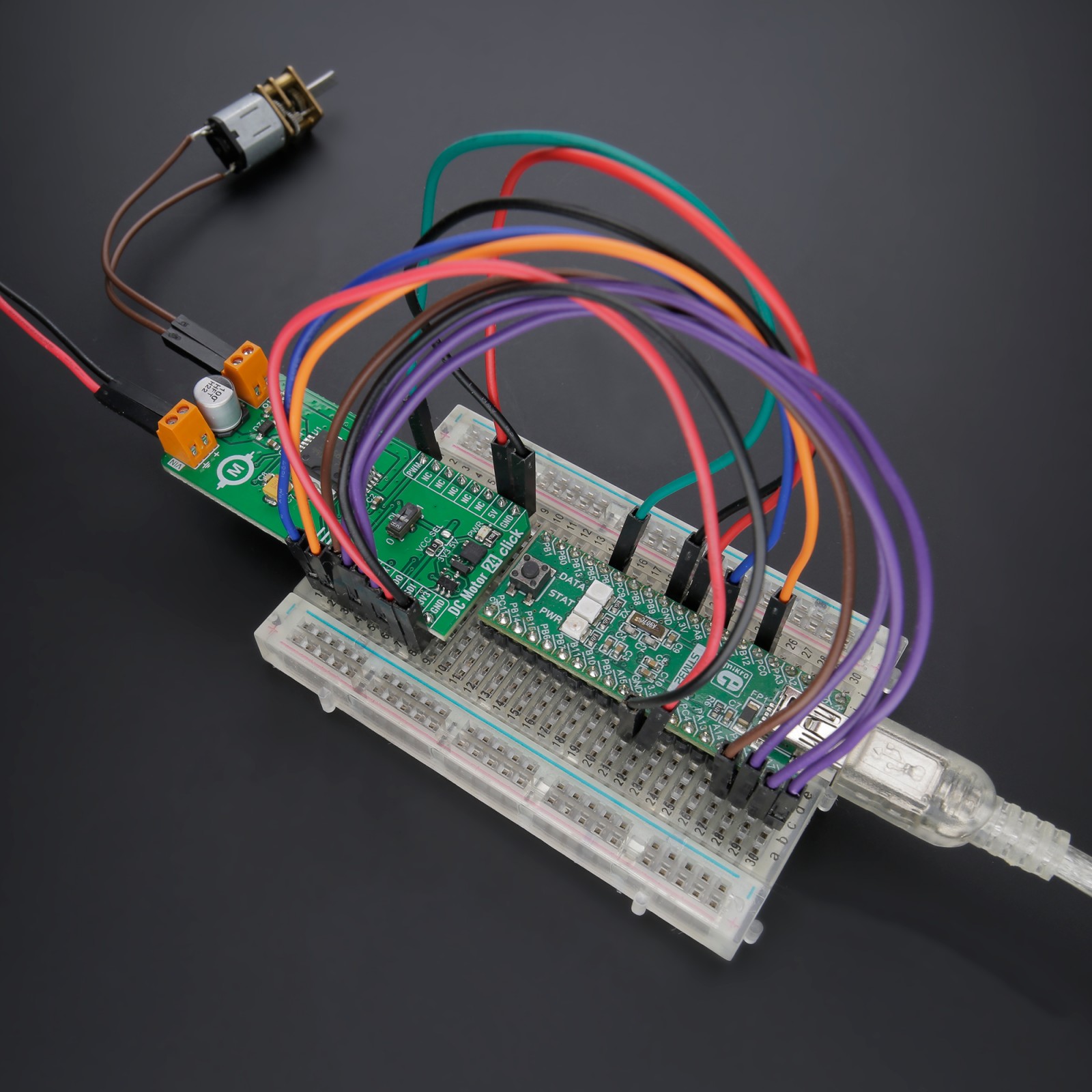

DC Motor 24 Click is a compact add-on board with a brushed DC motor driver. This board features the L9958, an SPI-controlled H-bridge from STMicroelectronics. The L9958 is rated for an operating voltage range from 4V to 28V, with direct PWM motor control and current regulation threshold set by the SPI interface from 2.5A to 8.6A. It also has complete diagnostic and protection capabilities supporting the robust and reliable operation. This Click board™ is suitable for controlling DC and stepper motors in safety-critical automotive applications and under extreme environmental conditions.

DC Motor 24 Click is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. What sets this Click board™ apart is the groundbreaking ClickID feature, enabling your host system to seamlessly and automatically detect and identify this add-on board.

NOTE: A compatible brushed DC motor does not come in the same package as this Click board™. If you are interested in one we offer, you can find DC Gear Motor – 430RPM (3-6V) in our shop.

Stock: Lead-time applicable.

| 5+ | R441.75 |

| 10+ | R418.50 |

| 15+ | R395.25 |

| 20+ | R380.37 |