Load Cell 7 Click

R535.00 ex. VAT

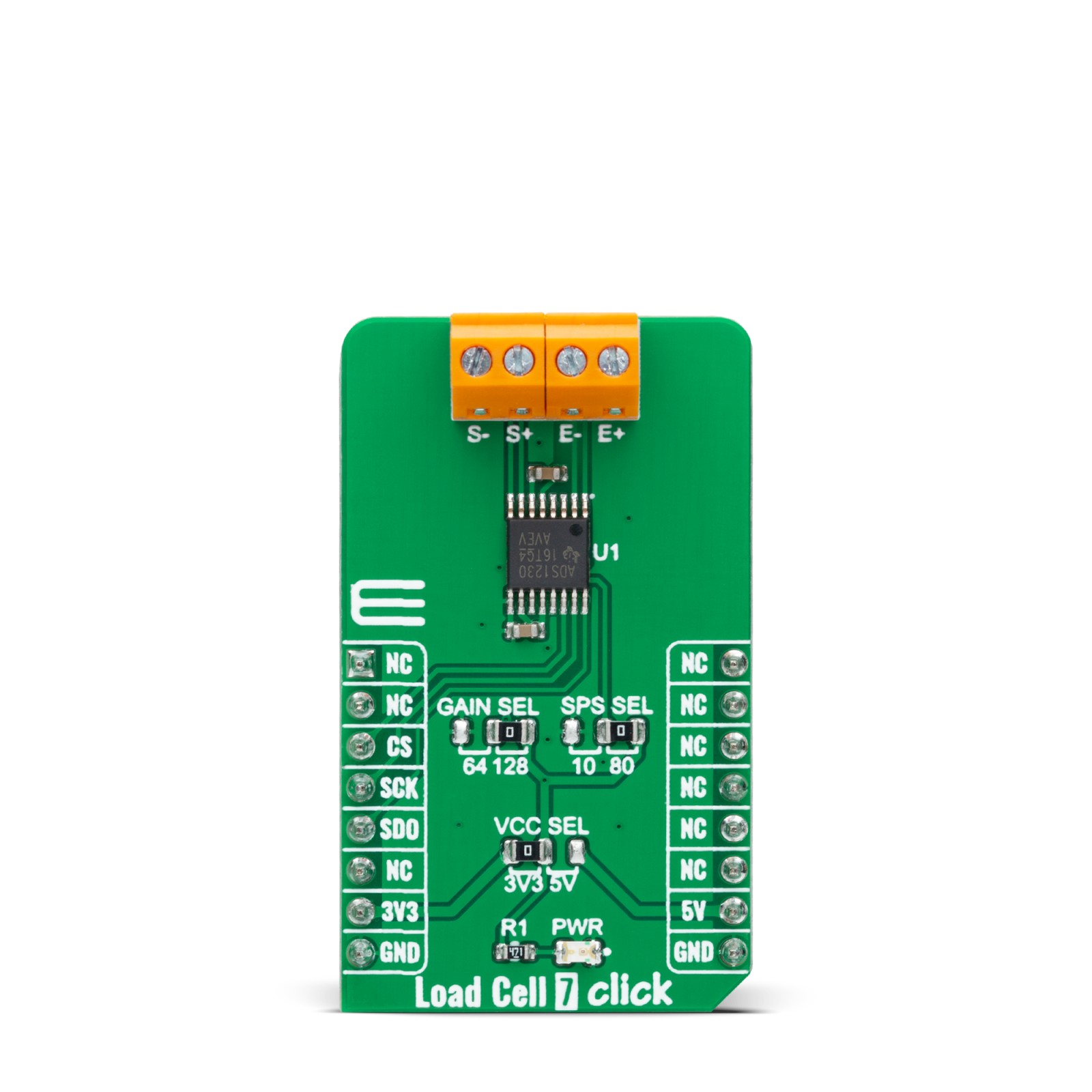

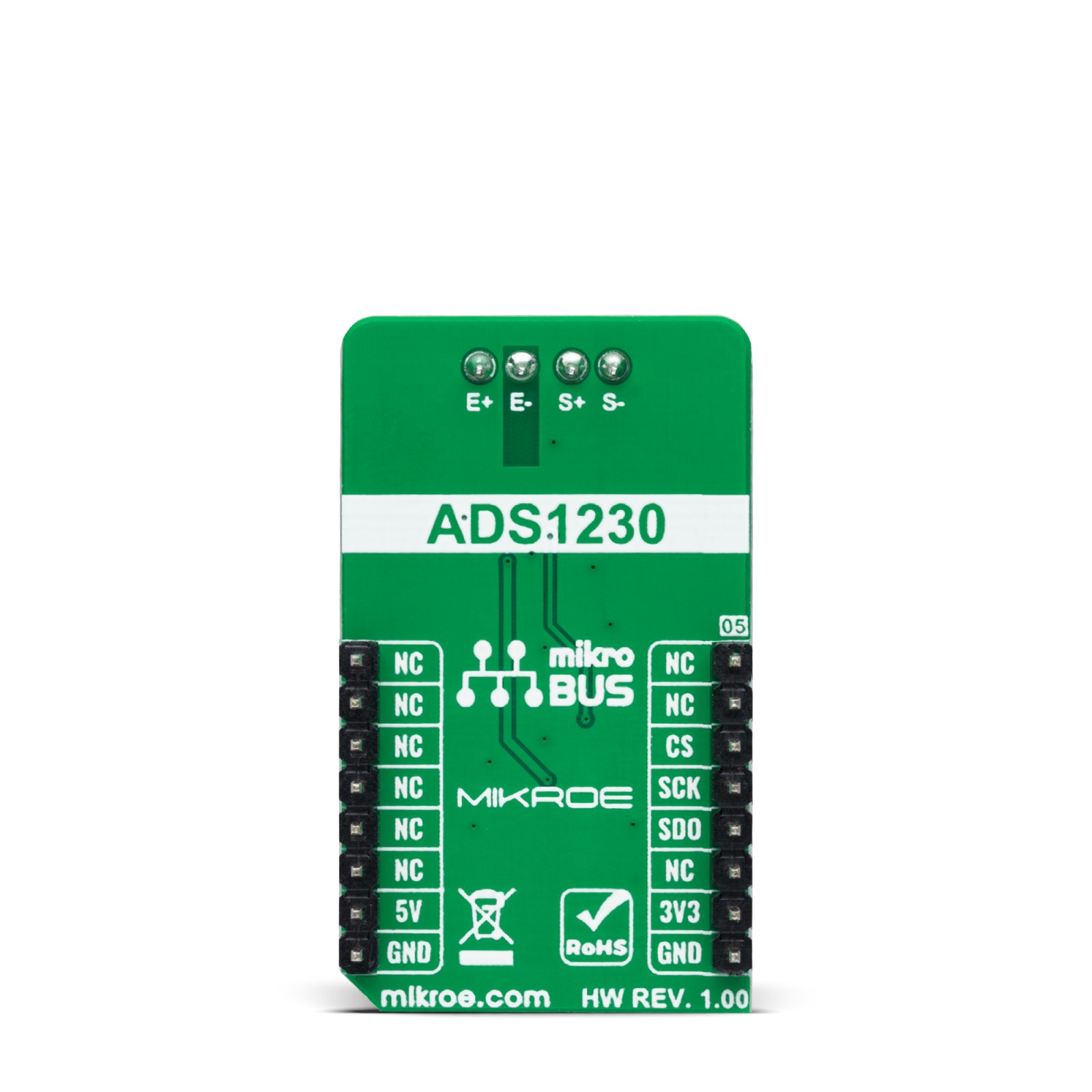

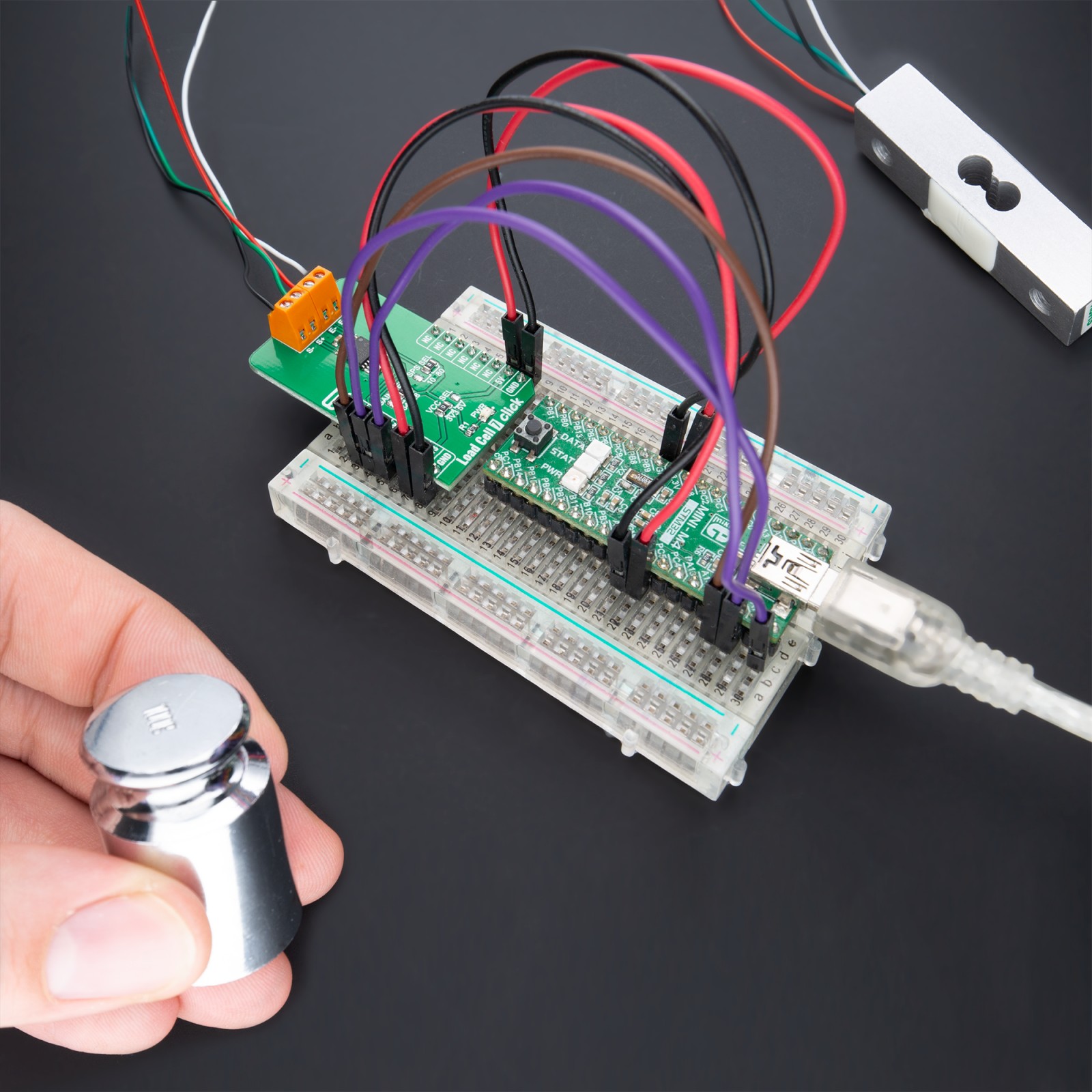

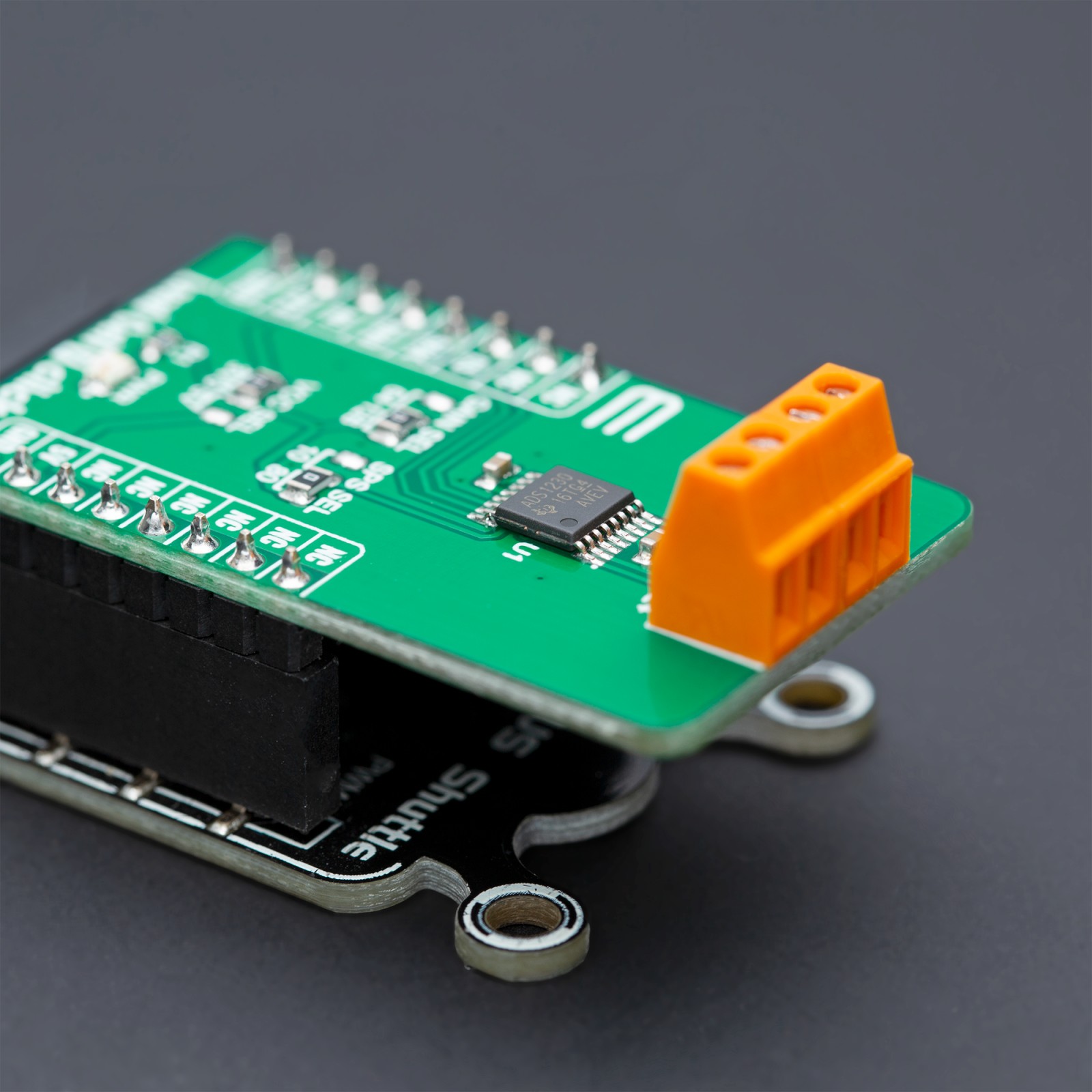

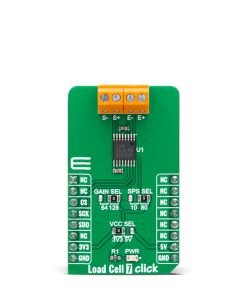

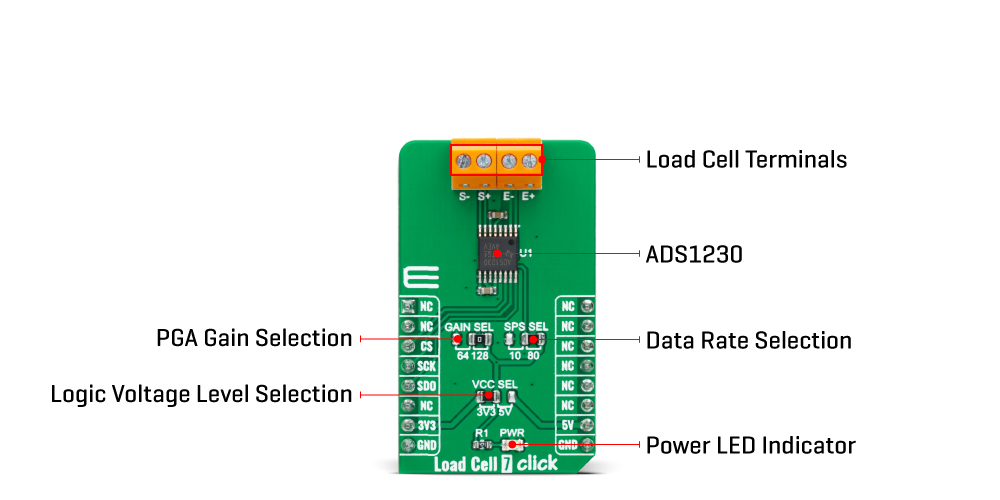

Load Cell 7 Click is a compact add-on board representing a weigh scale solution. This board features the ADS1230, a high-precision 20-bit delta-sigma analog-to-digital converter (ADC) with an outstanding noise performance from Texas Instruments. This SPI-configurable ADC (read-only) offers selectable gain and data rate values, supporting a full-scale differential input of ±39mV/±19.5mV and 10SPS/80SPS, respectively. It comes with an onboard low-noise programmable gain amplifier (PGA) and onboard oscillator providing a complete front-end solution. This Click board™ has many features that make it a perfect fit for bridge sensor applications, including industrial process control, weigh scales, and strain gauges.

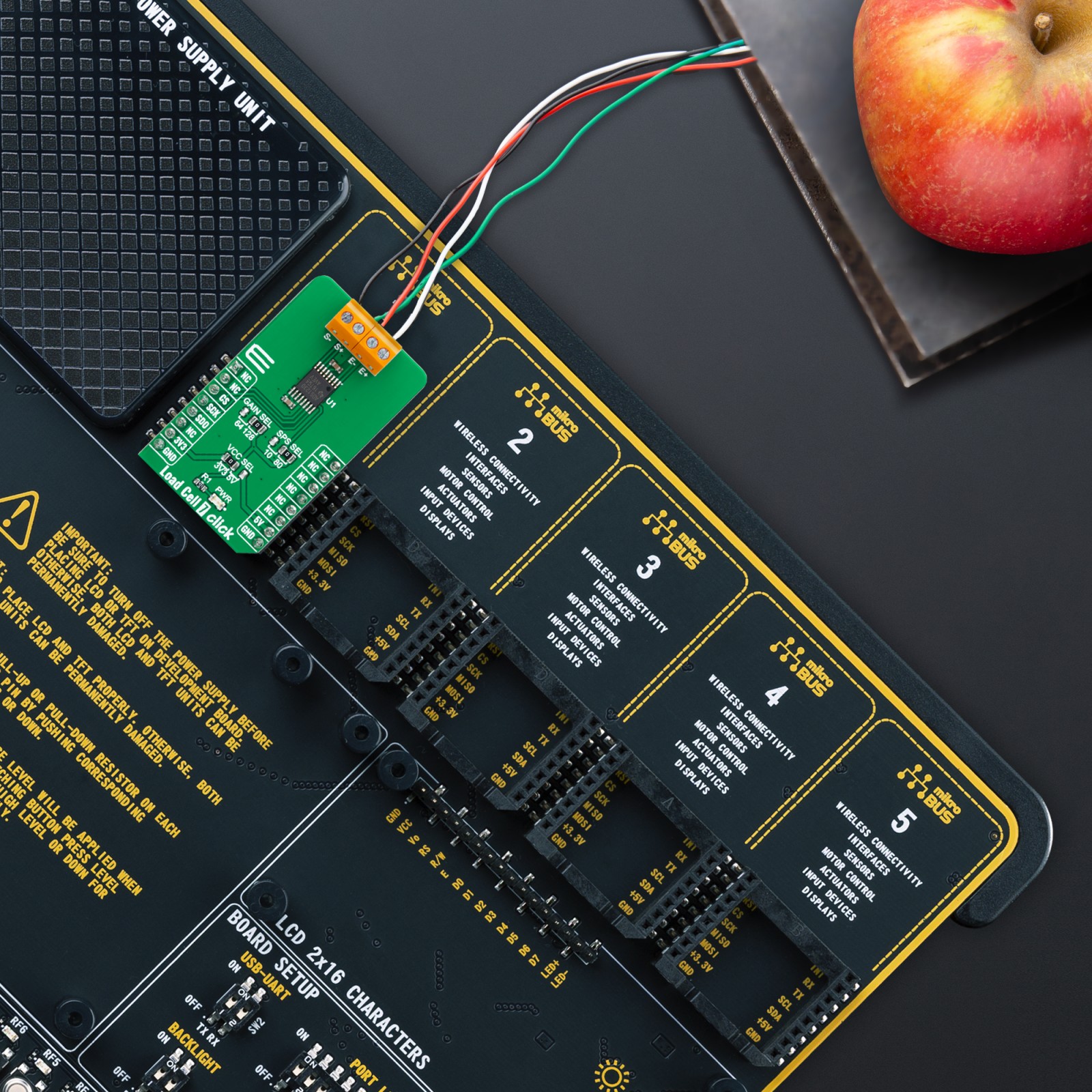

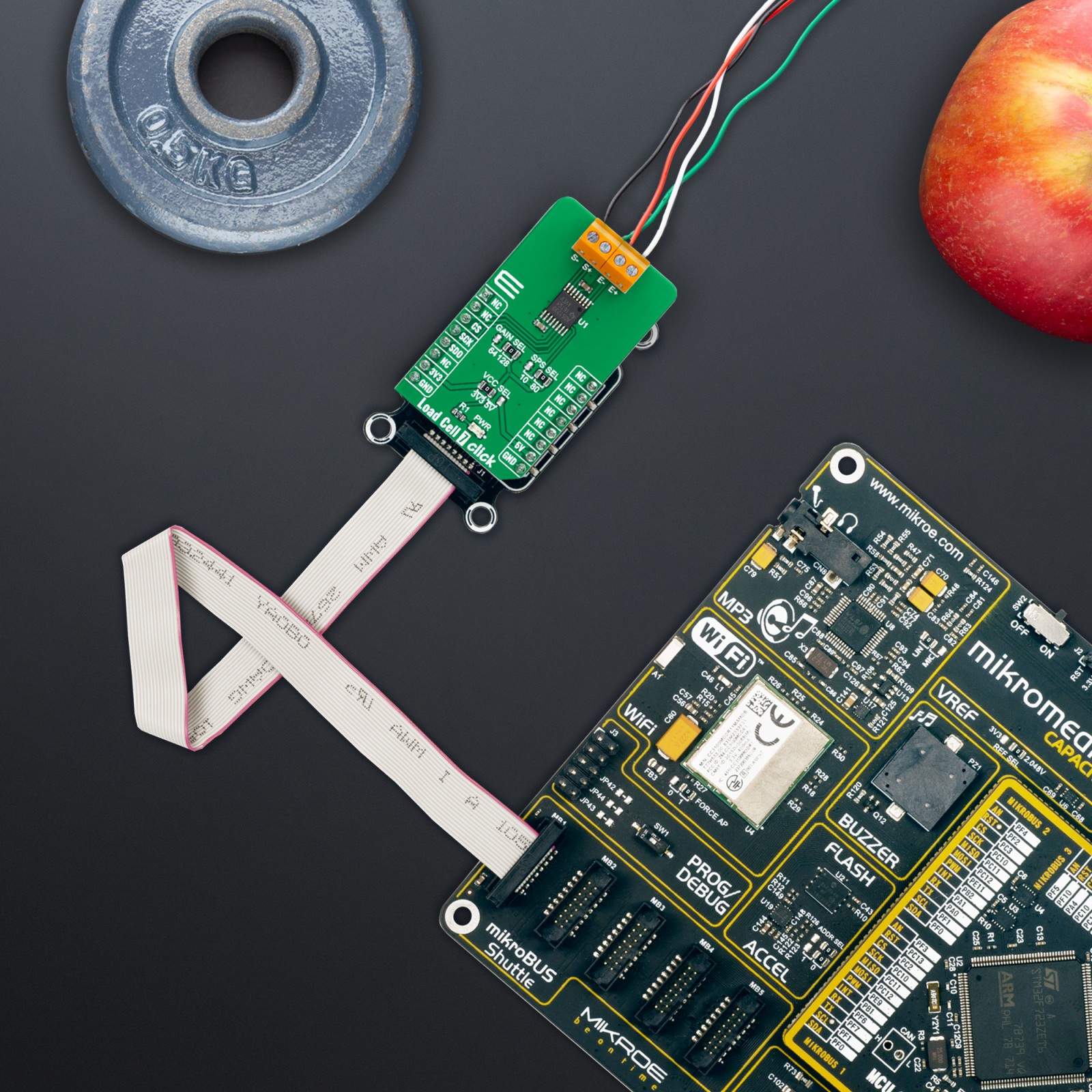

Load Cell 7 Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R508.25 |

| 10+ | R481.50 |

| 15+ | R454.75 |

| 20+ | R437.63 |