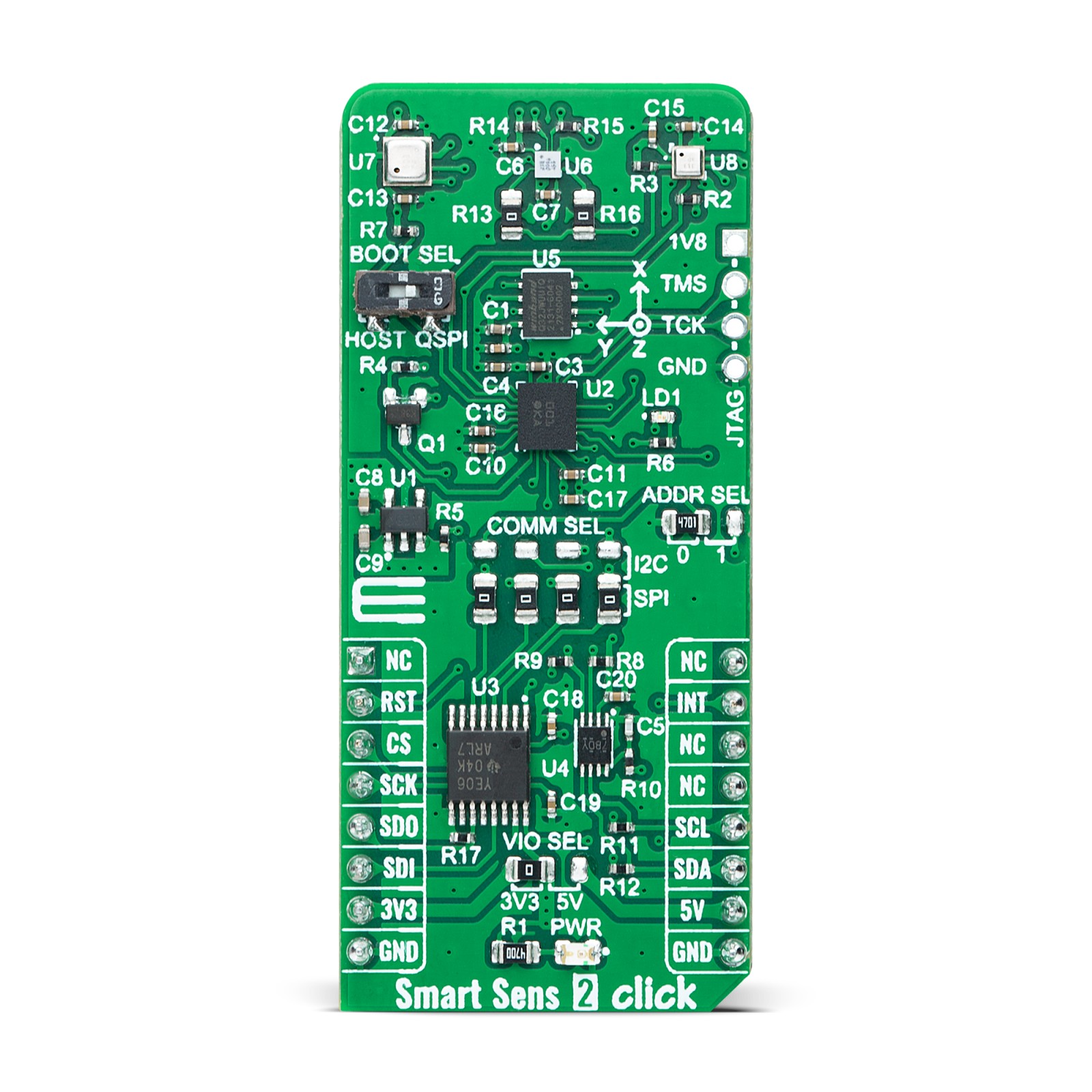

Smart Sens 2 Click

R1,000.00 ex. VAT

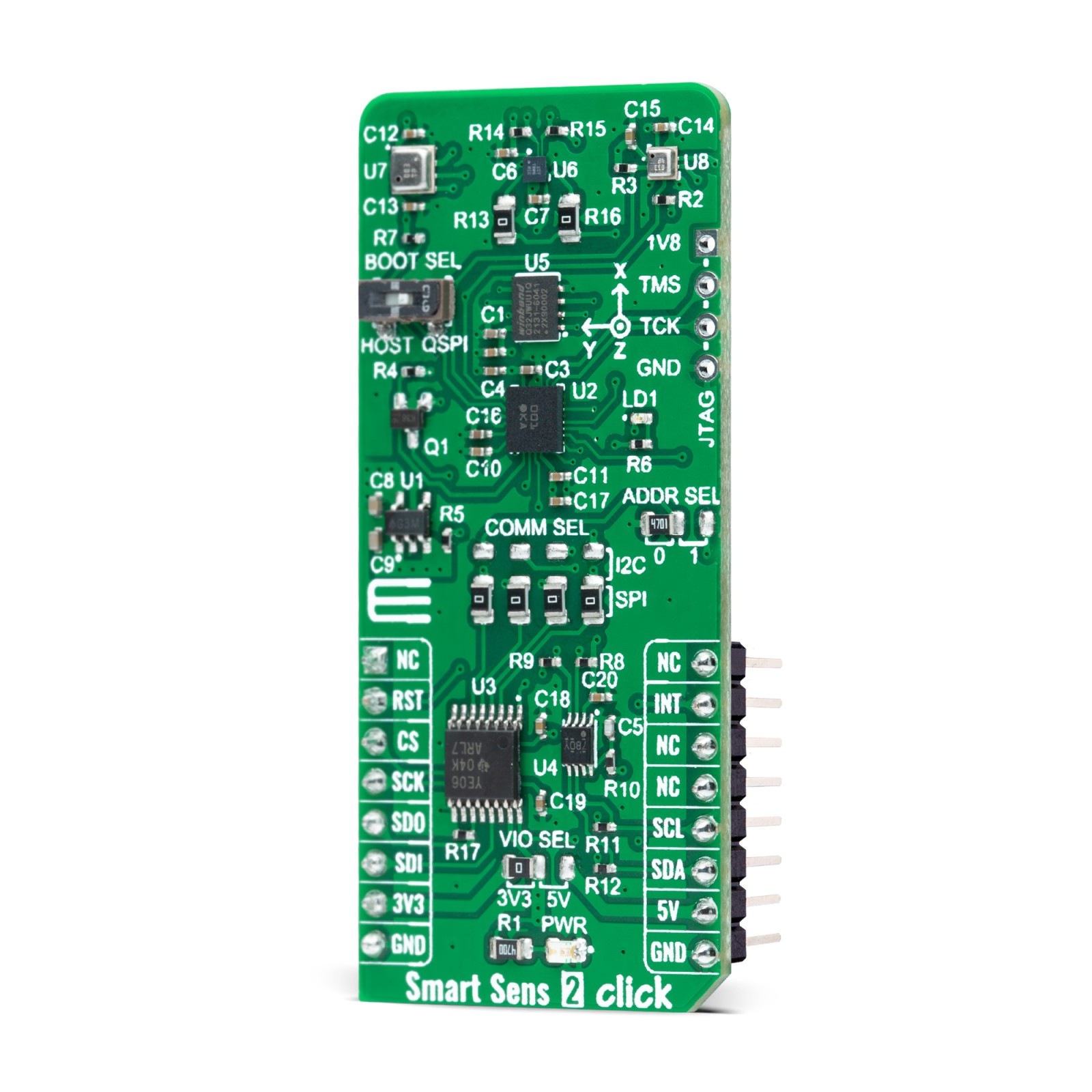

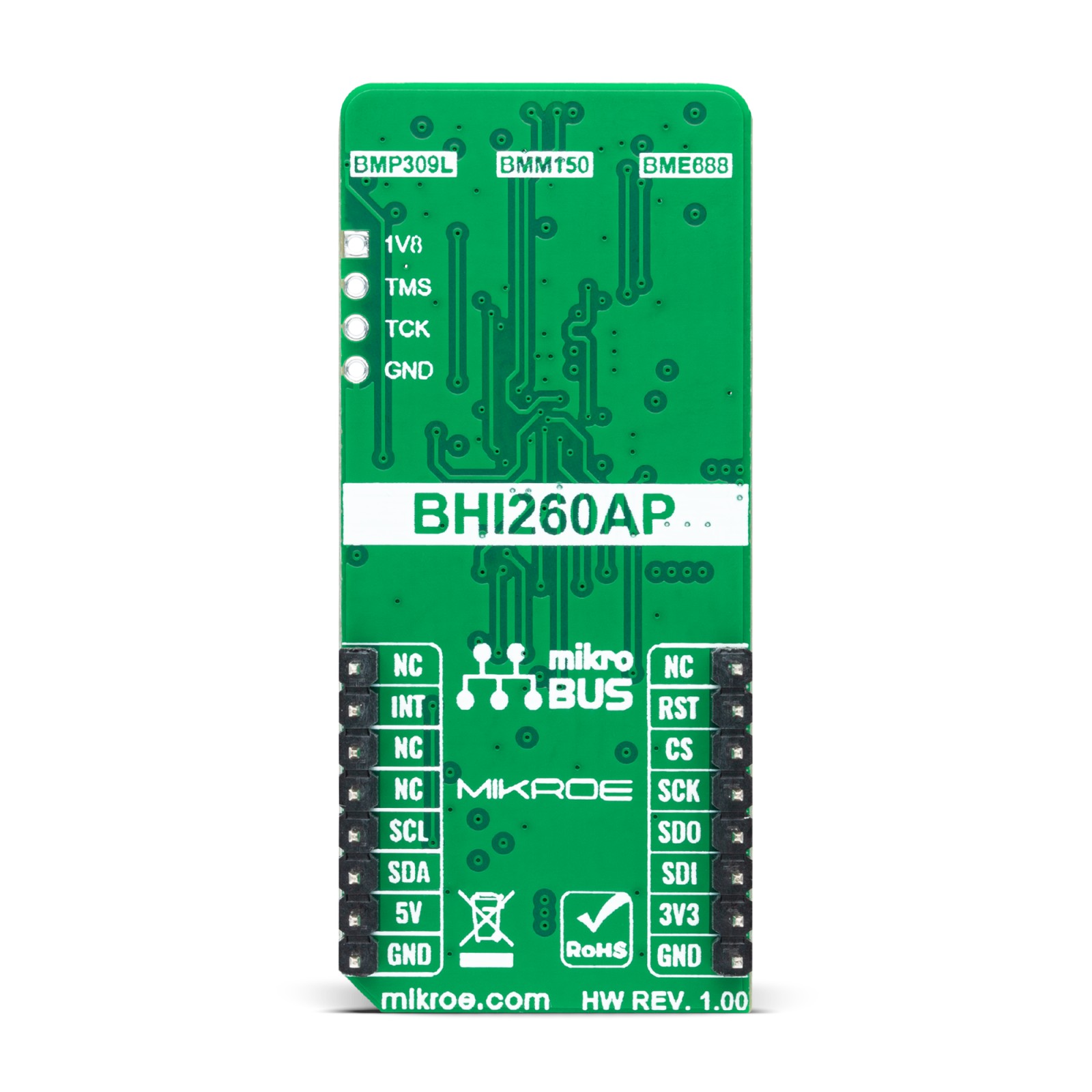

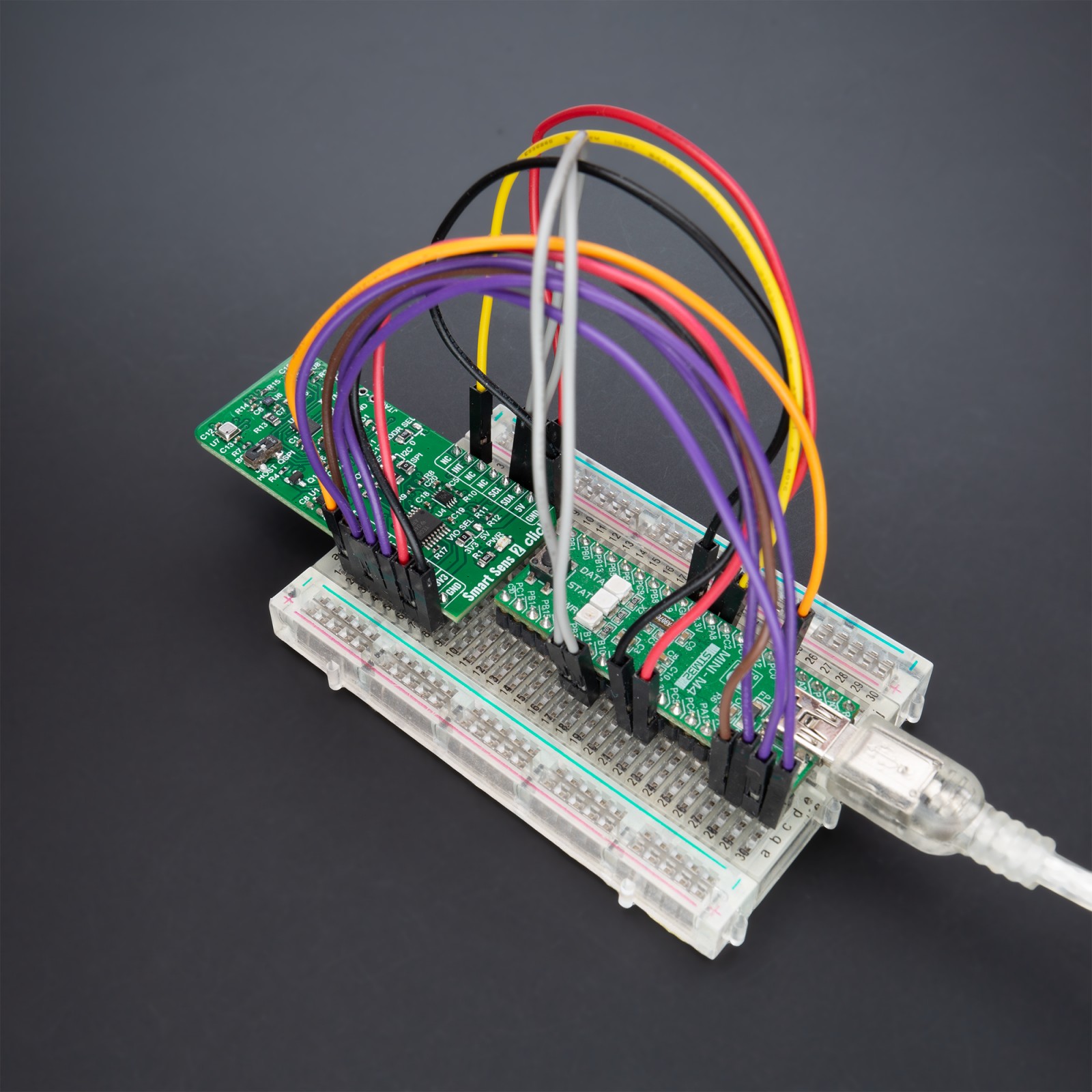

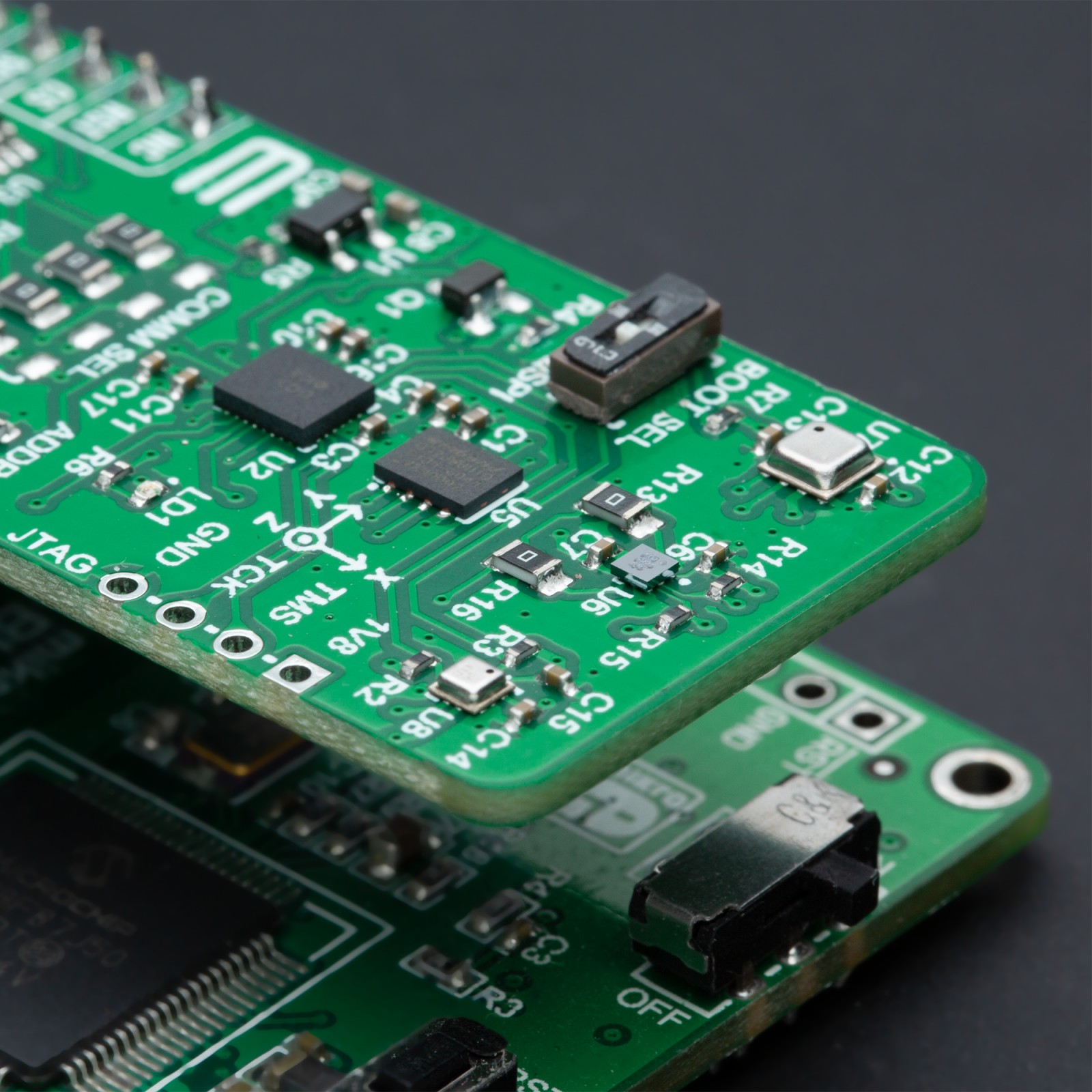

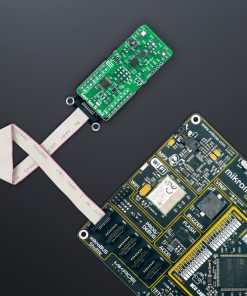

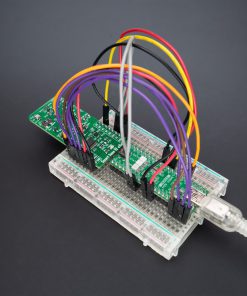

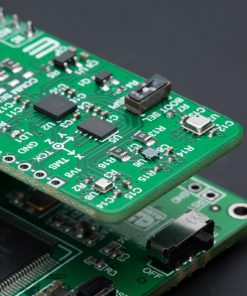

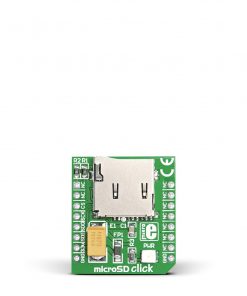

Smart Sens 2 Click is a all-in-one self-learning AI smart sensor solution that contains multiple sensors. This board utilizes the BHI260AP, BME688, BMP390, and BMM150, an ultra-low-power programmable smart sensor, environmental and pressure sensor, and a magnetometer from Bosch Sensortec. The BHI260AP includes a powerful 32-bit MCU and a 6-axis IMU (3-axis accelerometer and 3-axis gyroscope) alongside an event-driven software framework. In addition to its internal functions also perform signal data processing from several onboard sensors performing measurements of various parameters such as an environmental and magnetic field. In addition to these primary functions, this Click board™ allows users to select the desired serial interface, use the debug interface, and select BOOT mode. This Click board™ represents an ideal solution for always-on sensor data processing algorithms at the lowest power consumption.

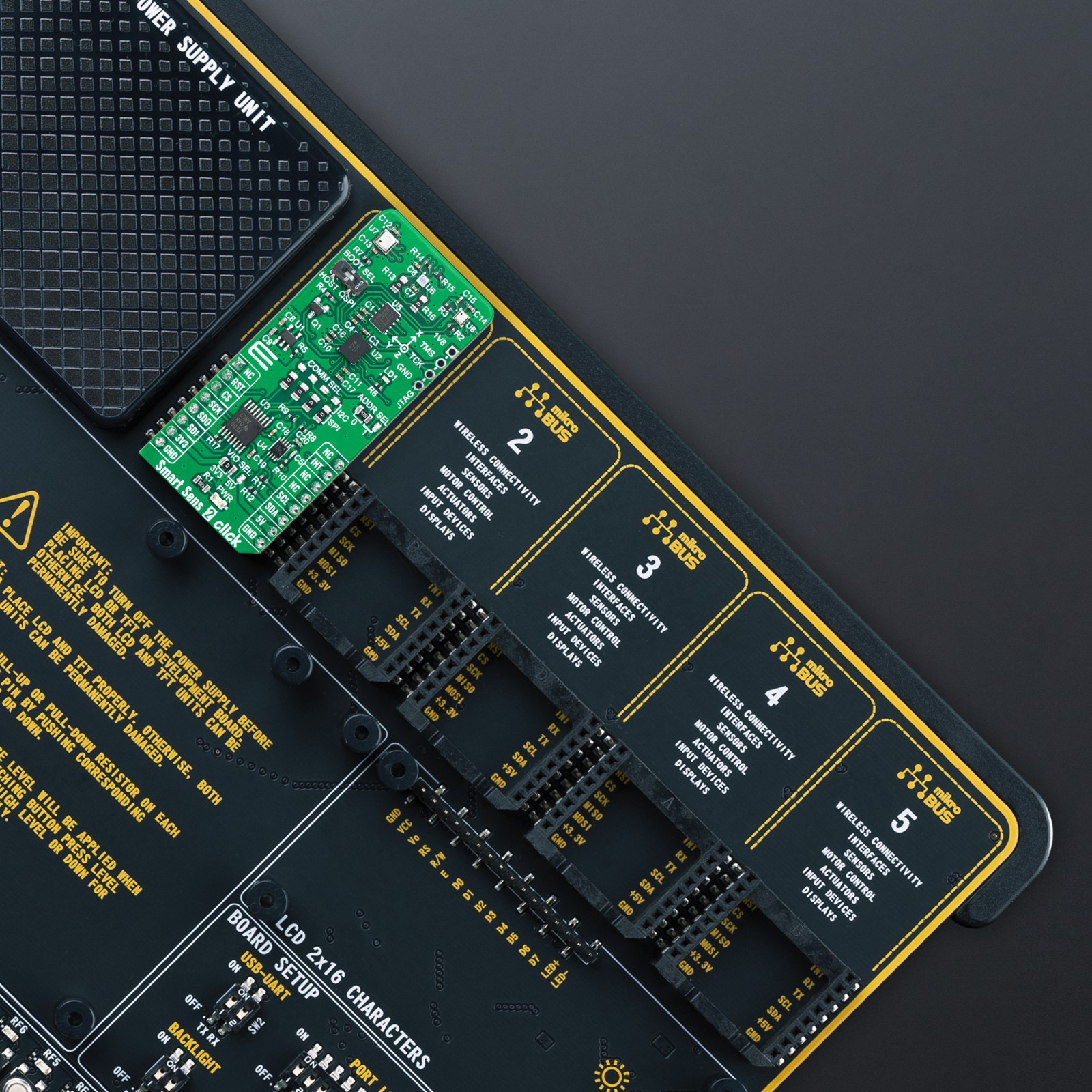

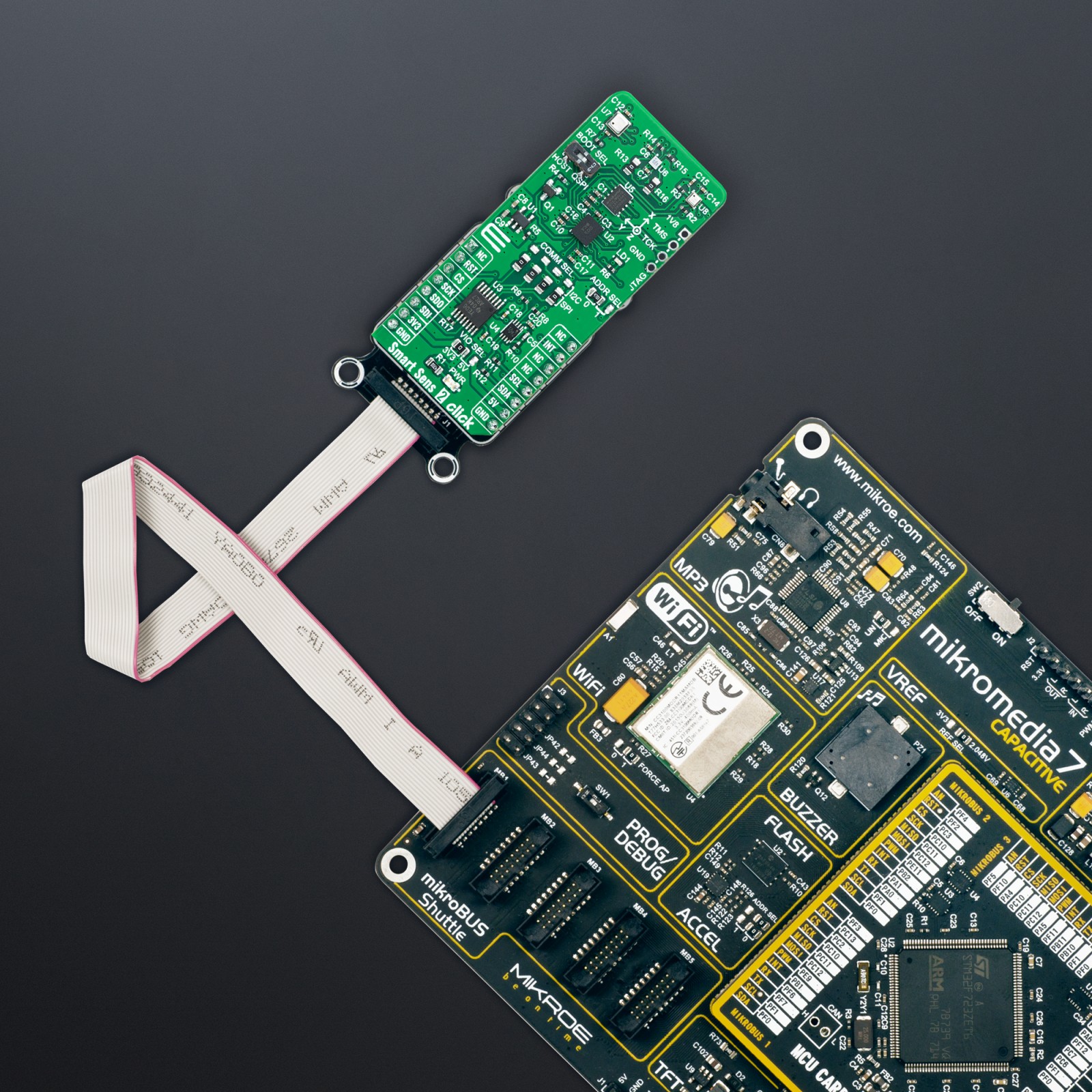

Smart Sens 2 Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R950.00 |

| 10+ | R900.00 |

| 15+ | R850.00 |

| 20+ | R818.00 |