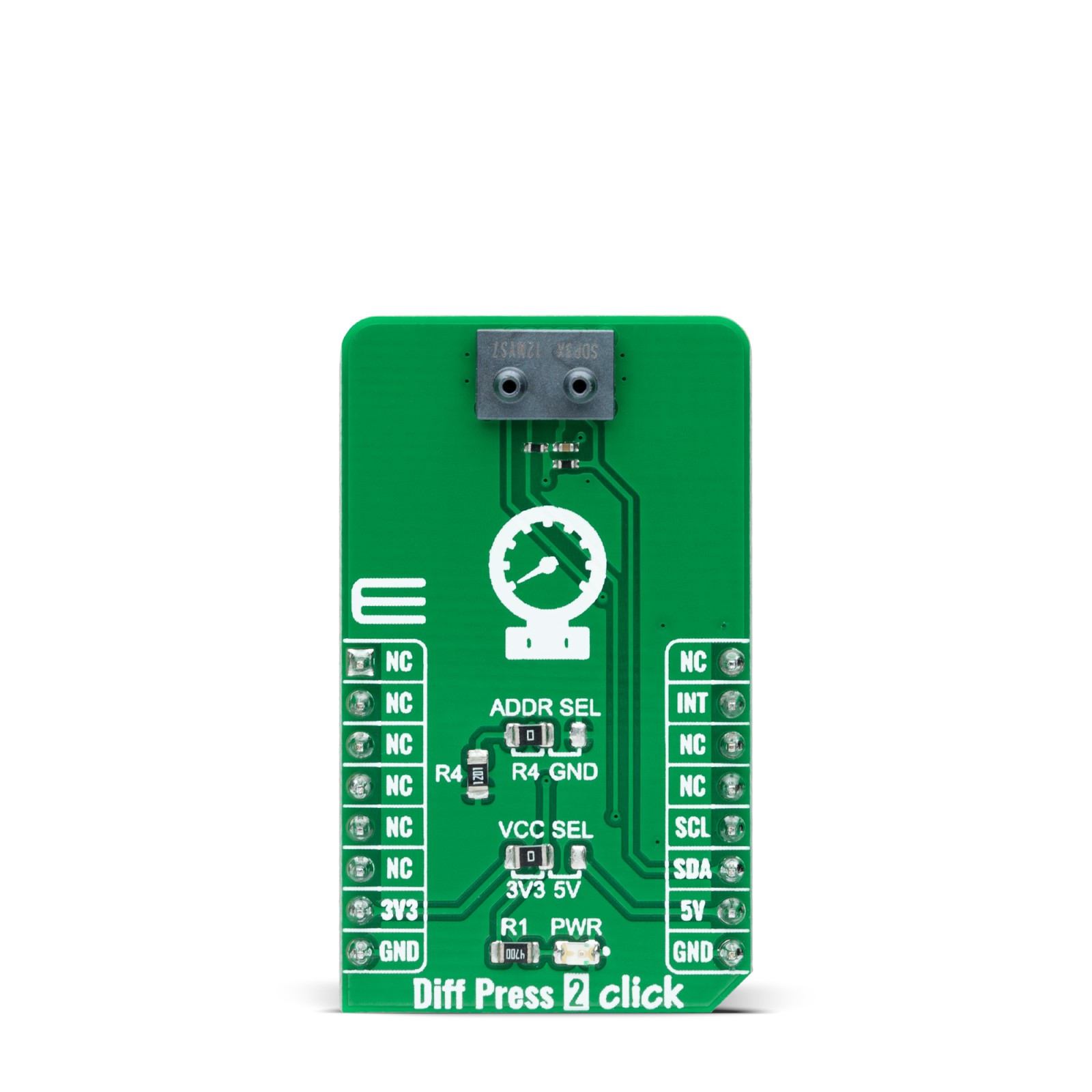

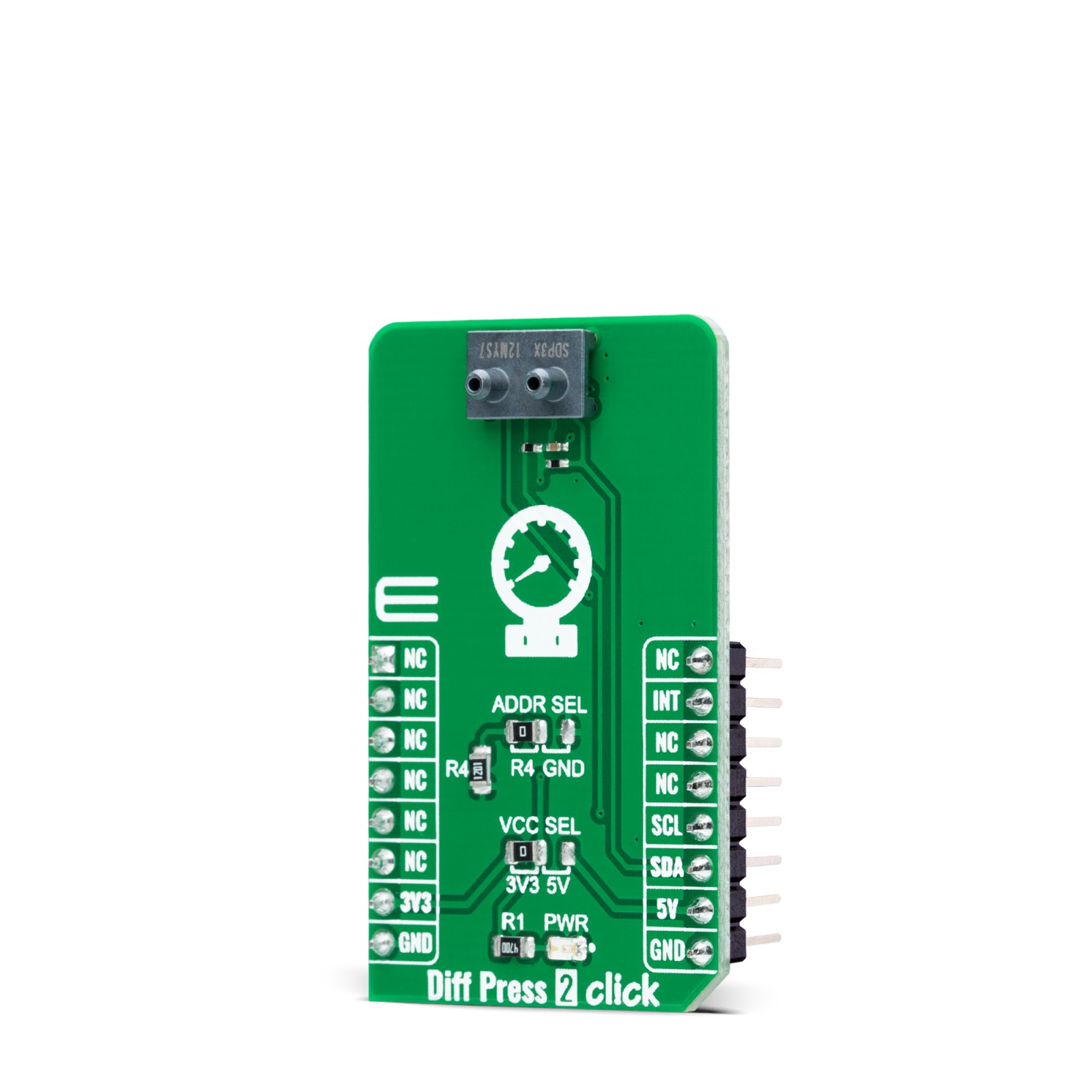

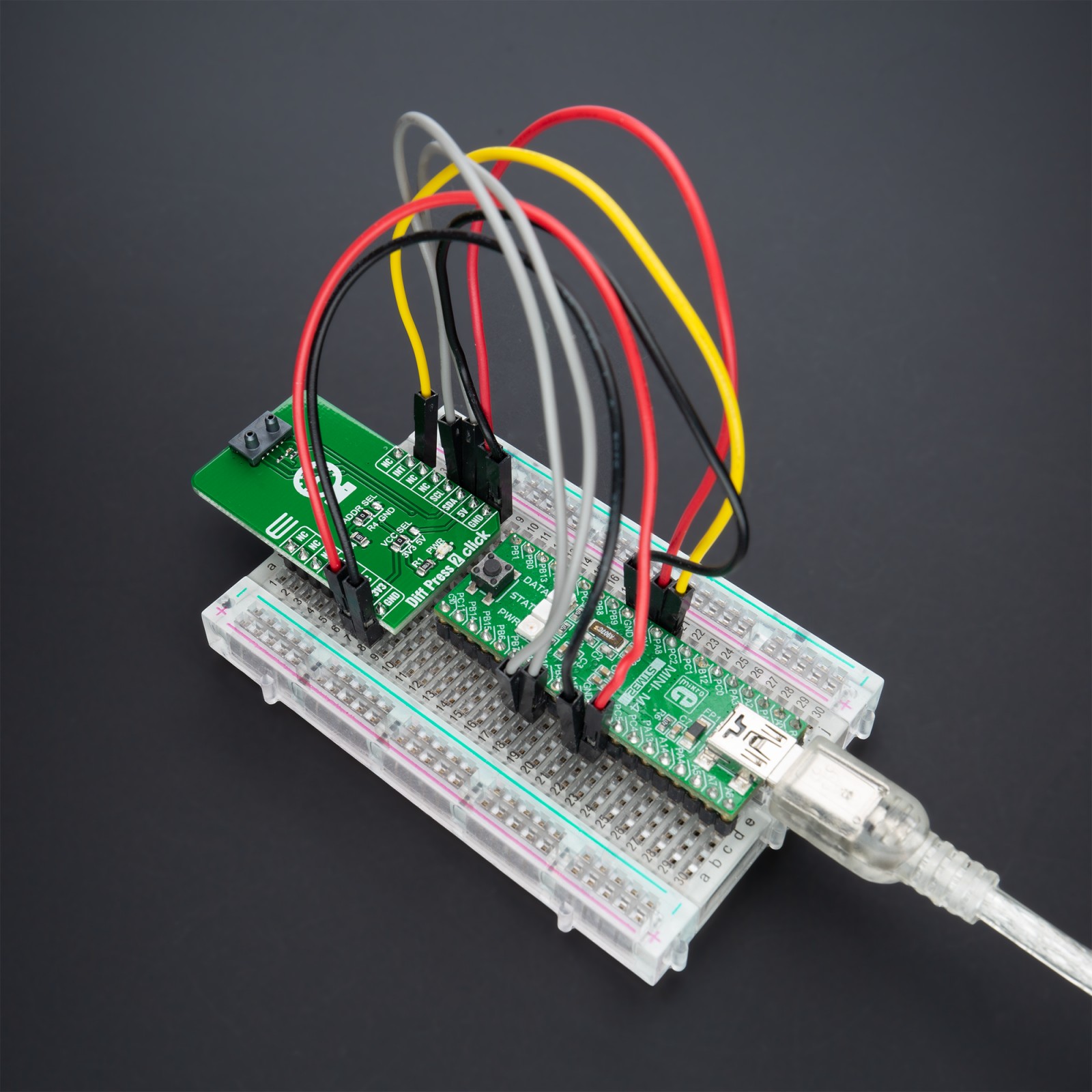

Diff Press 2 Click

R1,150.00 ex. VAT

Diff Press 2 Click is a compact add-on board that contains Sensirion’s differential pressure sensor. This board features the SDP31-500PA, a small differential pressure sensor designed for high-volume applications. The SDP31-500PA comes with a configurable host interface that supports I2C serial communication and measures pressure in a range from -500Pa up to +500Pa with an accuracy of 3%. It comes as calibrated and temperature compensated with high reliability/long-term stability, has the best signal-to-noise ratio. It operates in a temperature range of -40°C to 85°C, ensuring stable operation under extreme conditions. This Click board™ is suitable for weather station equipment, industrial, consumer applications, and similar applications which rely on accurate and reliable pressure monitoring.

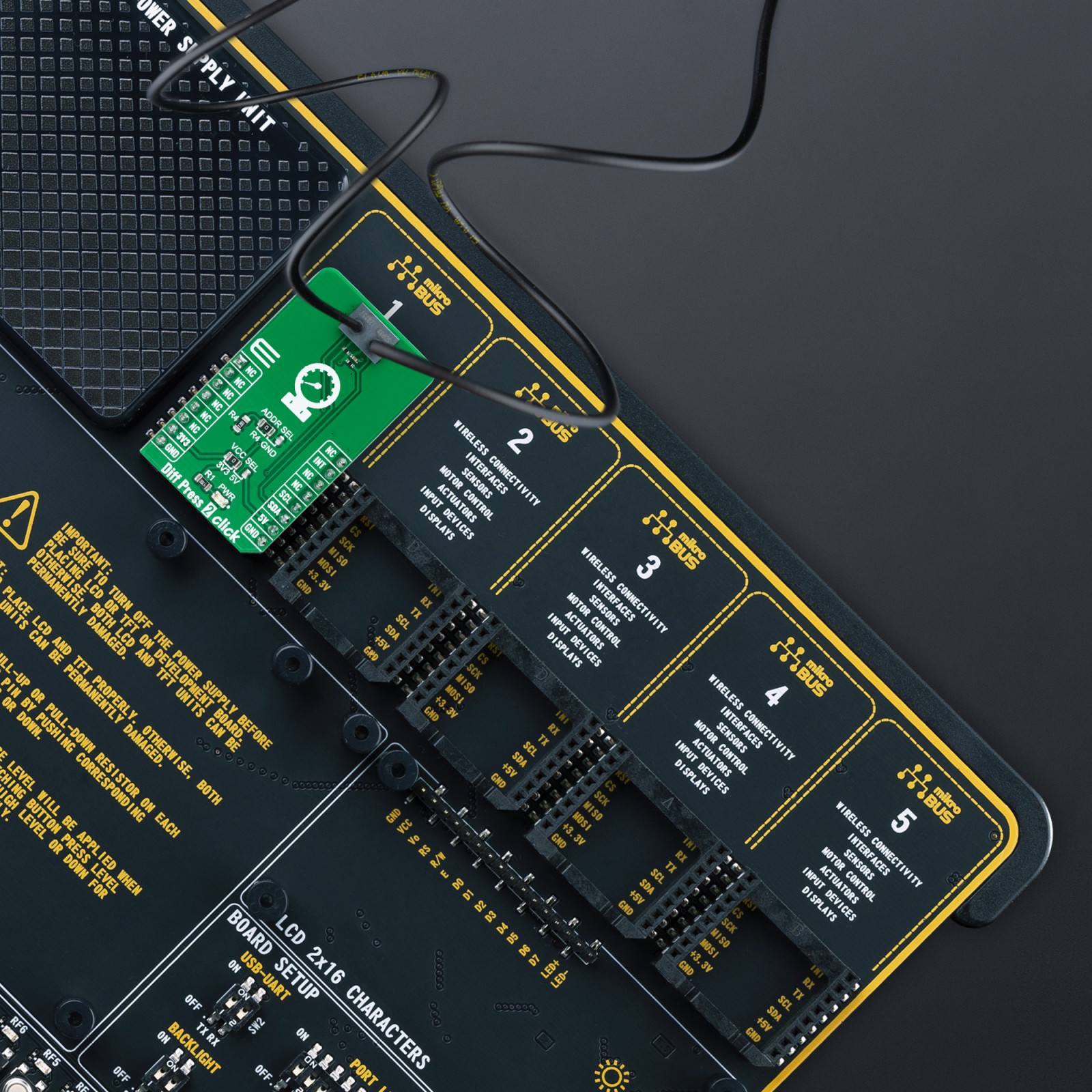

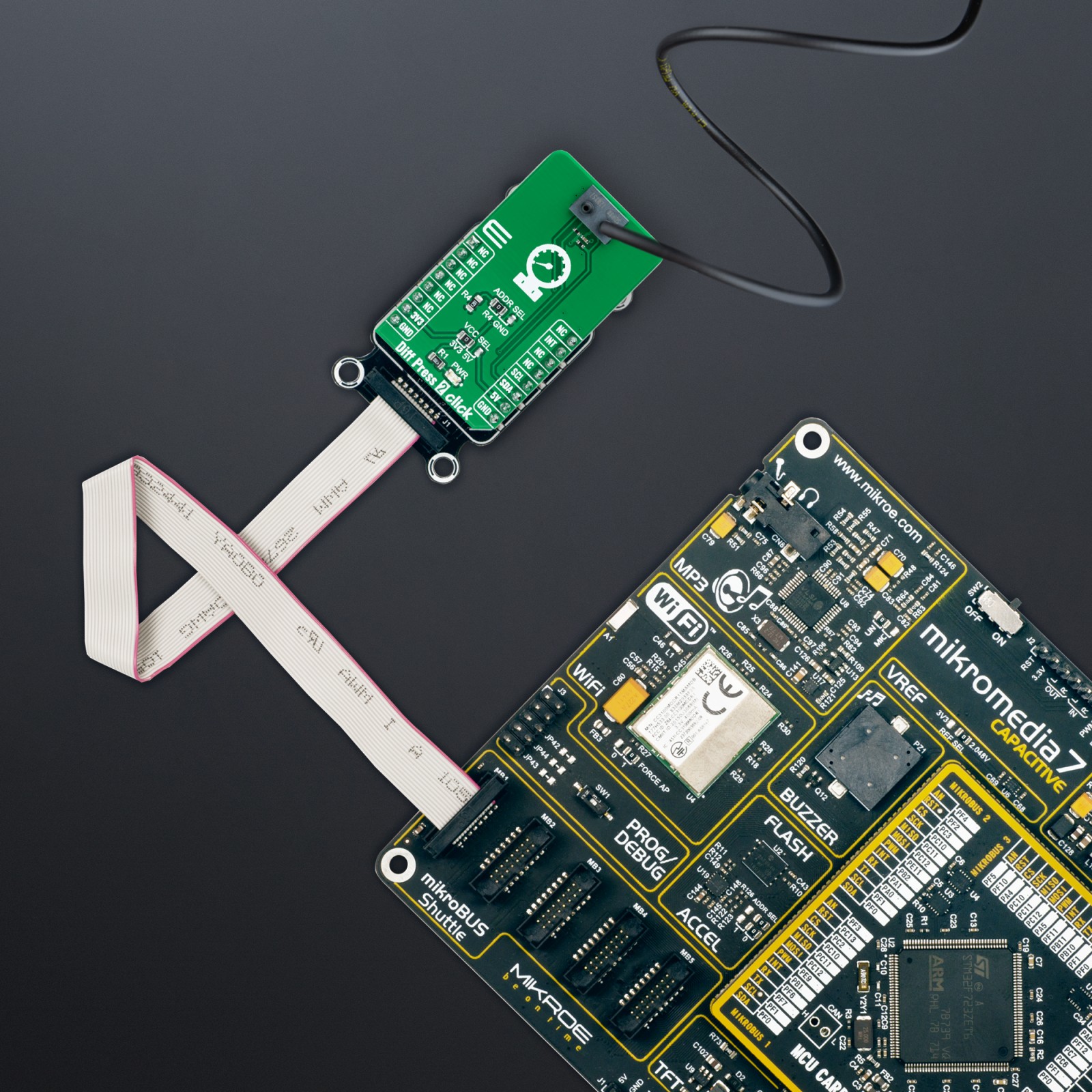

Diff Press 2 Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R1,092.50 |

| 10+ | R1,035.00 |

| 15+ | R977.50 |

| 20+ | R940.70 |