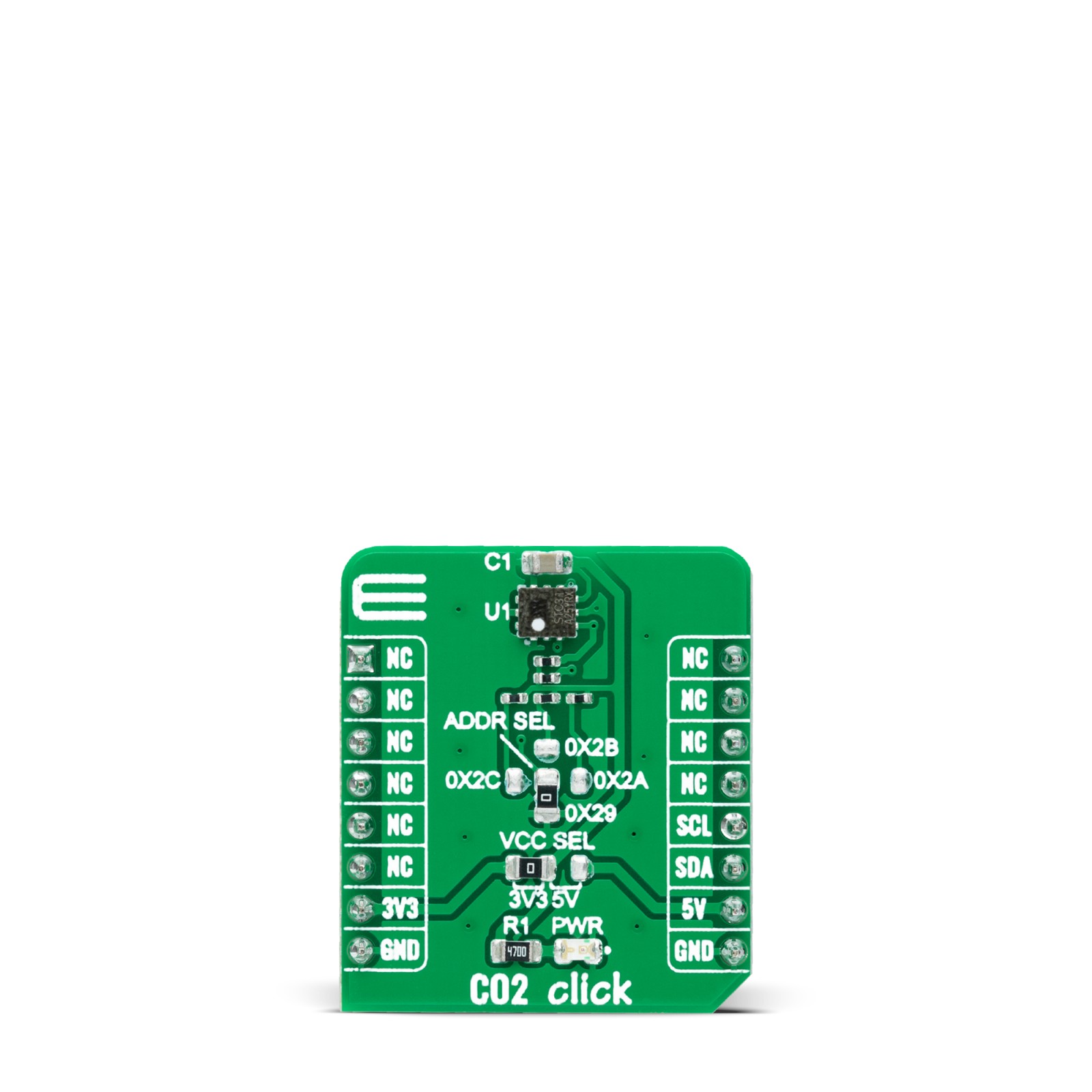

CO2 Click

R2,100.00 ex. VAT

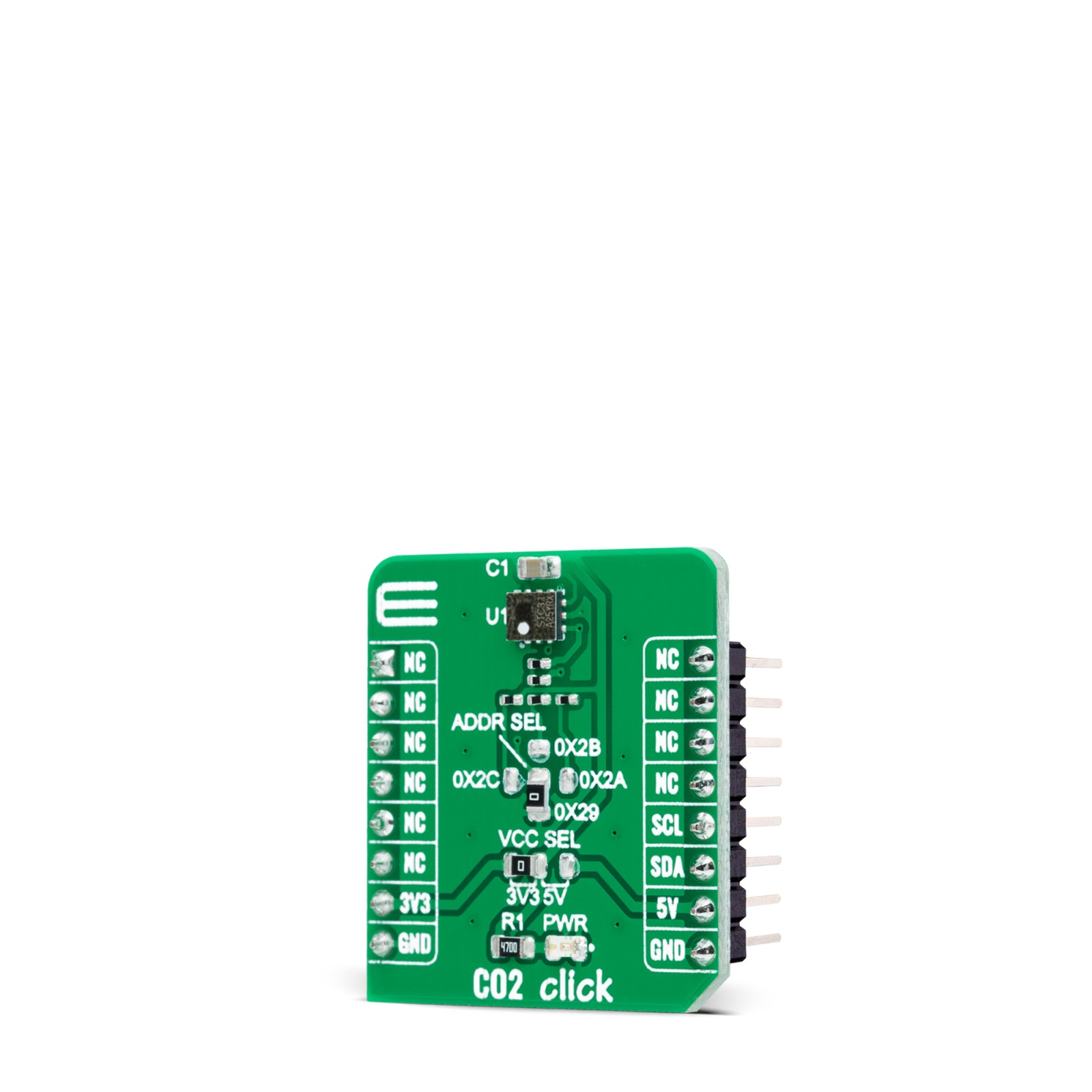

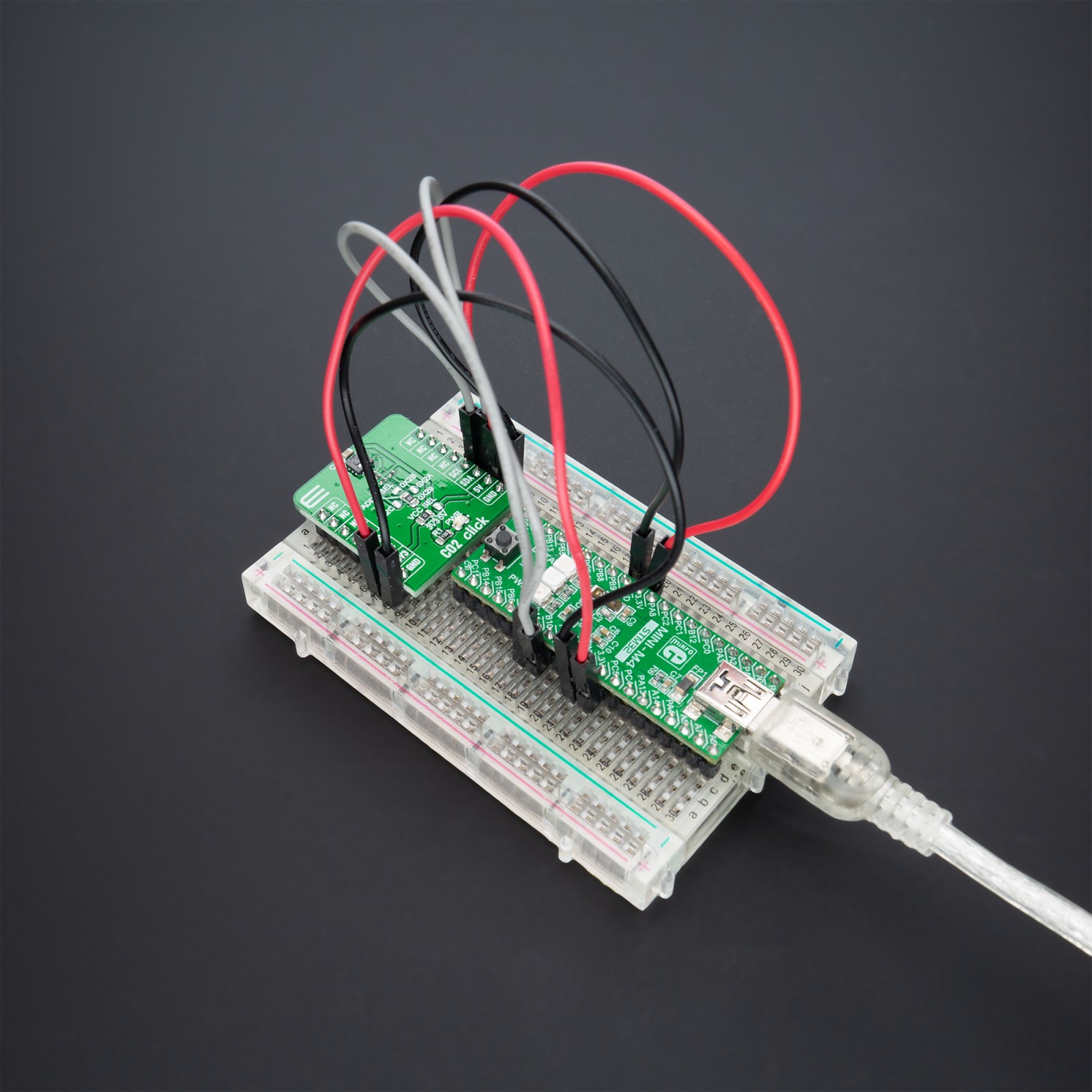

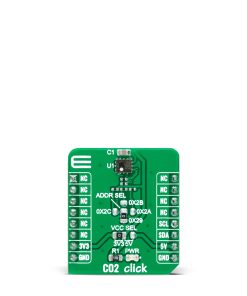

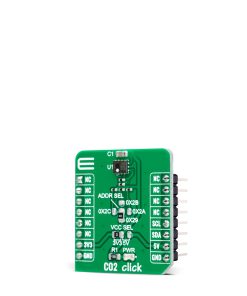

CO2 Click is a compact add-on board that contains Sensirion’s miniature CO2 sensor. This board features the STC31, a gas concentration sensor designed for high-volume applications. The STC31 utilizes a revolutionized thermal conductivity measurement principle, which results in superior repeatability and long-term stability. The outstanding performance of these sensors is based on Sensirion’s patented CMOSens® sensor technology, which combines the sensor element, signal processing, and digital calibration on a small CMOS chip. It features a digital I2C interface, which makes it easy to connect directly to MCU. This Click board™ represents an ideal choice for health, environmental, industrial, residential monitoring of high CO2 concentrations and applications where reliability is crucial.

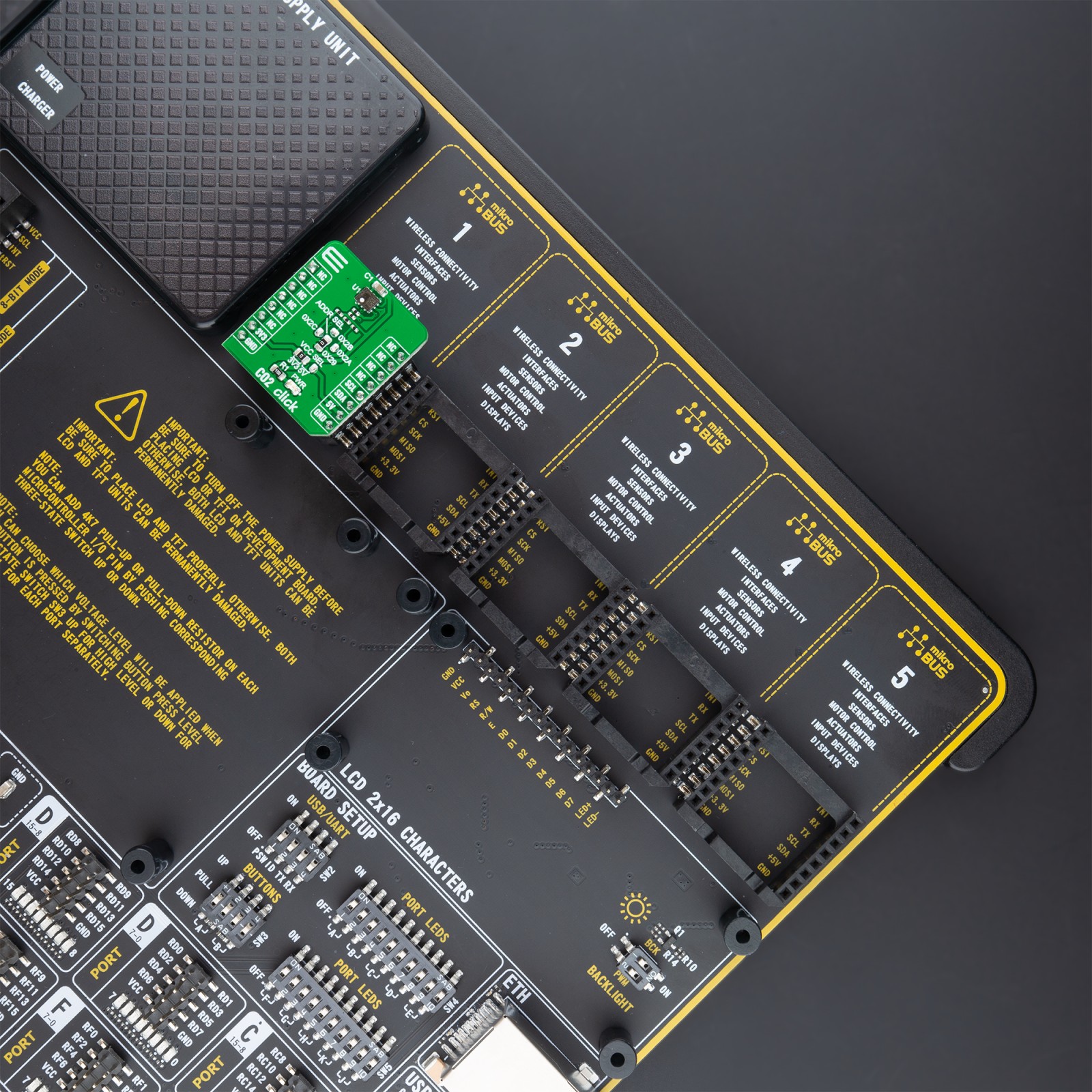

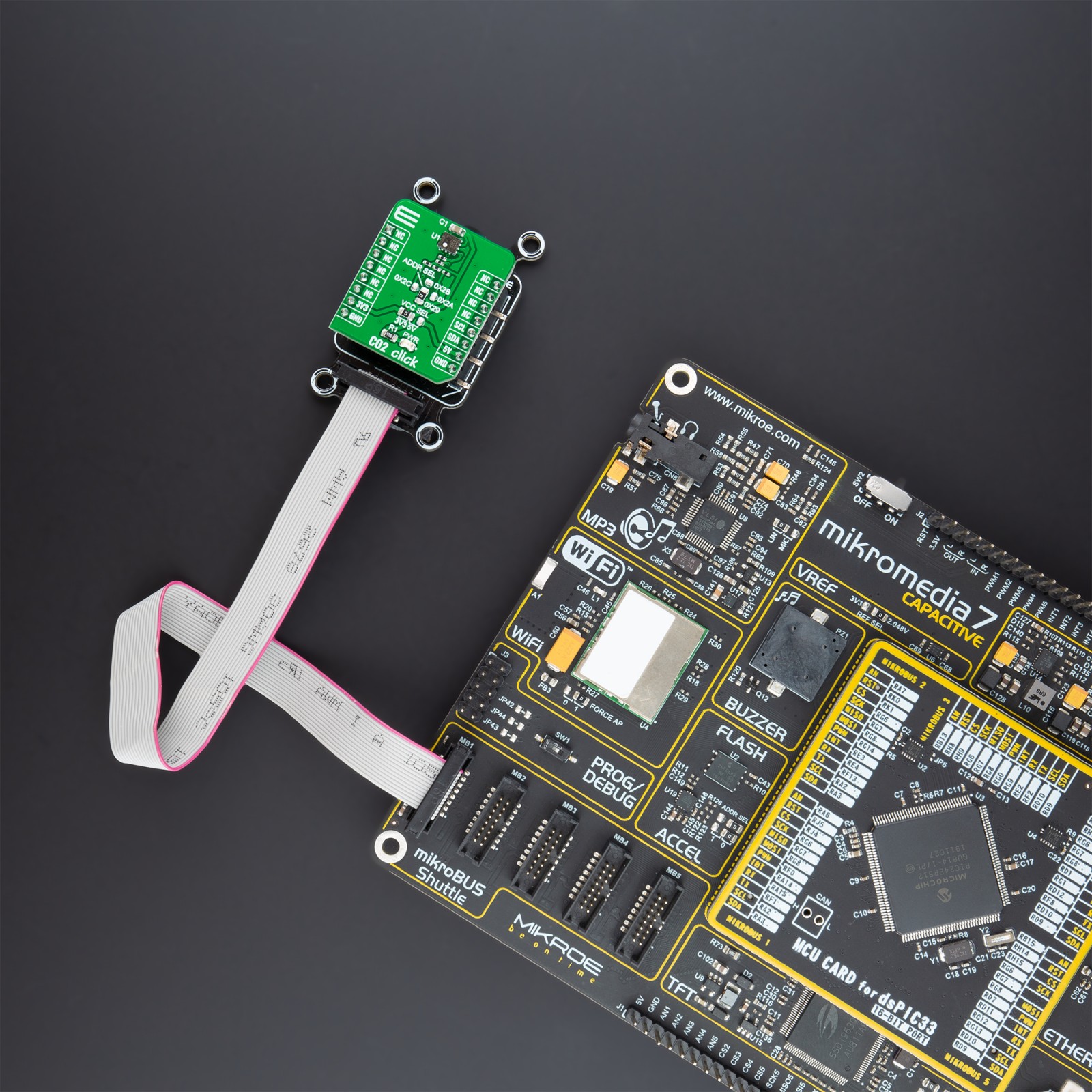

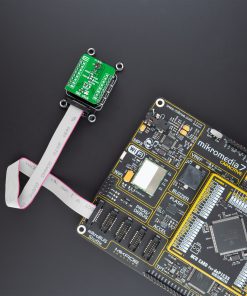

CO2 Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R1,995.00 |

| 10+ | R1,890.00 |

| 15+ | R1,785.00 |

| 20+ | R1,717.80 |