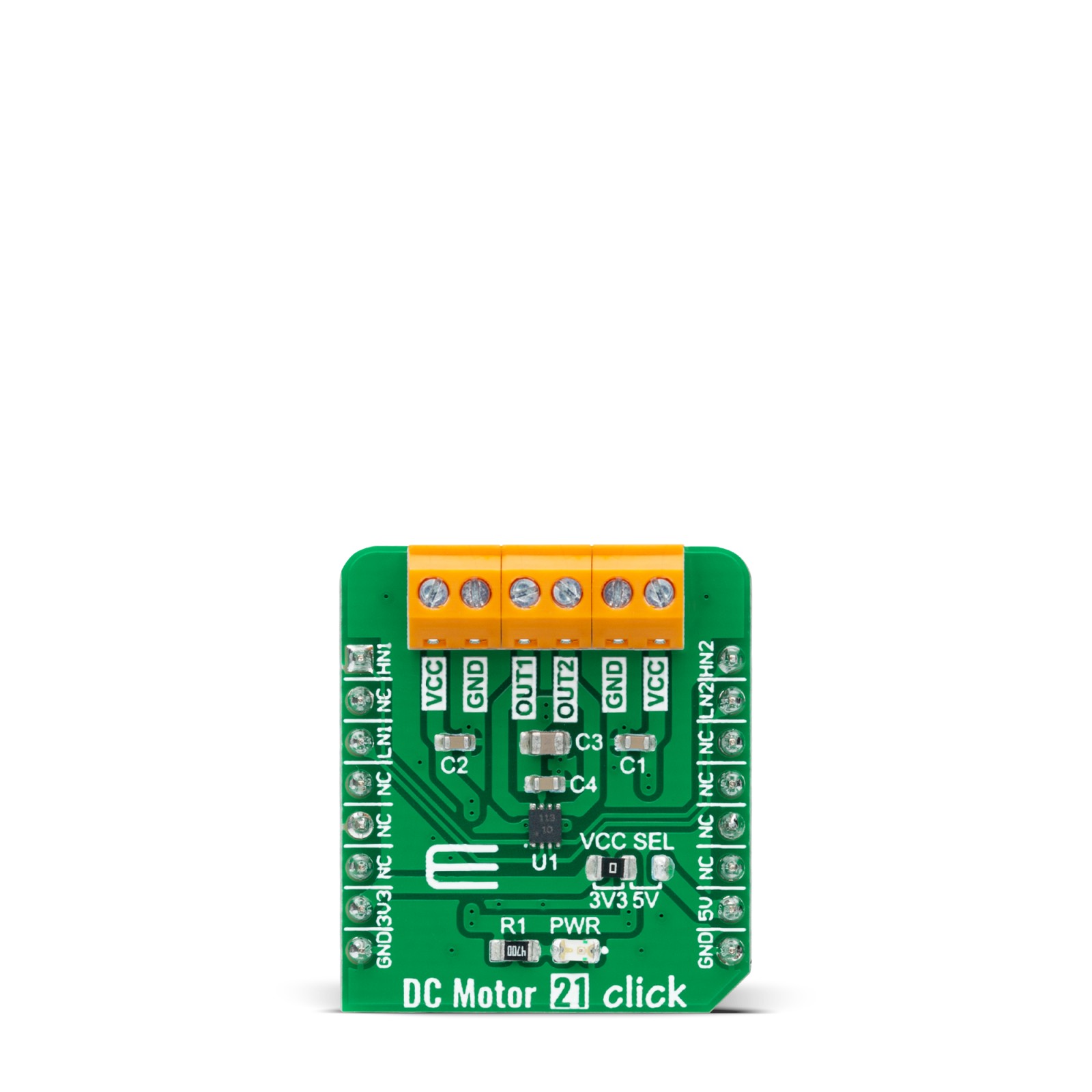

DC Motor 21 Click

R125.00 ex. VAT

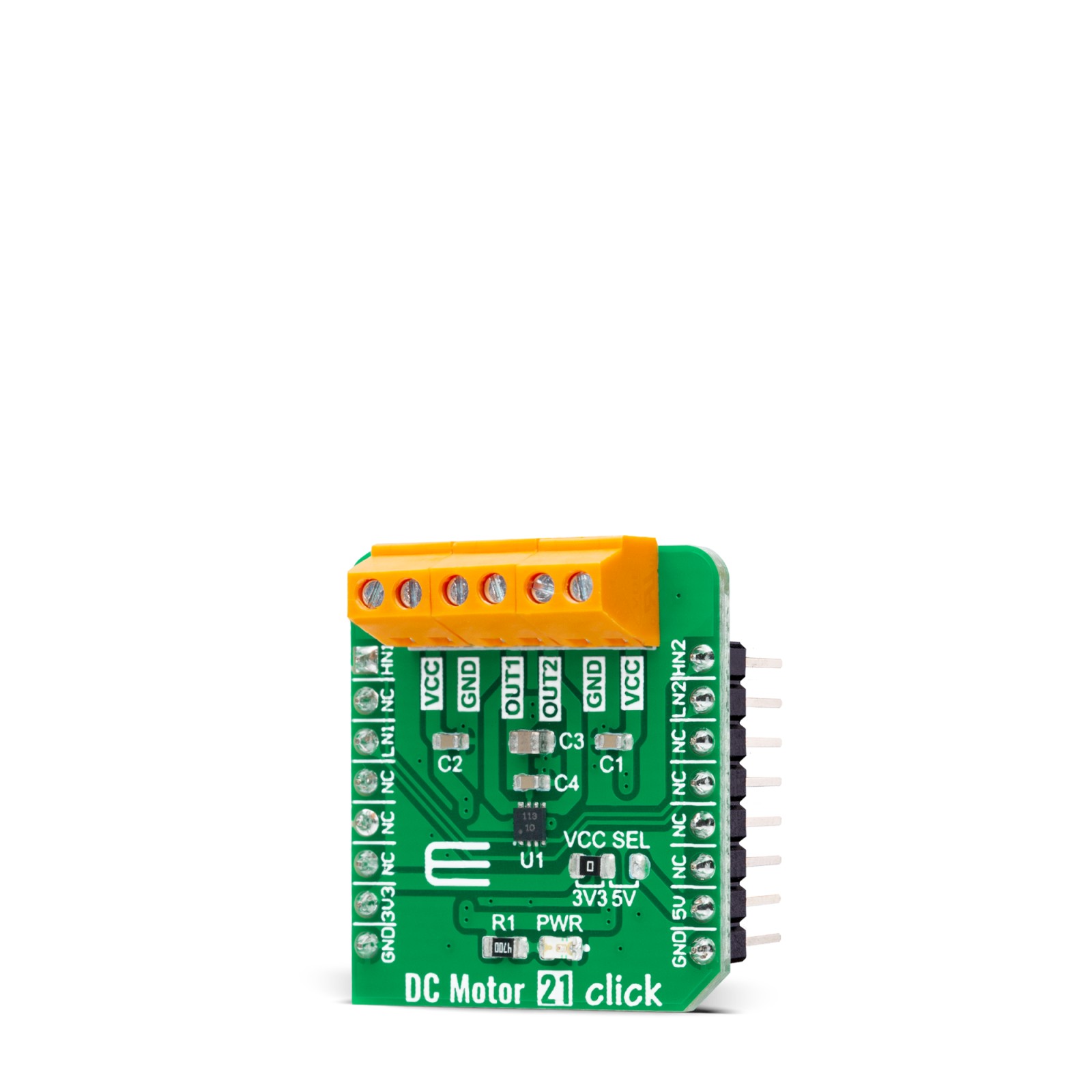

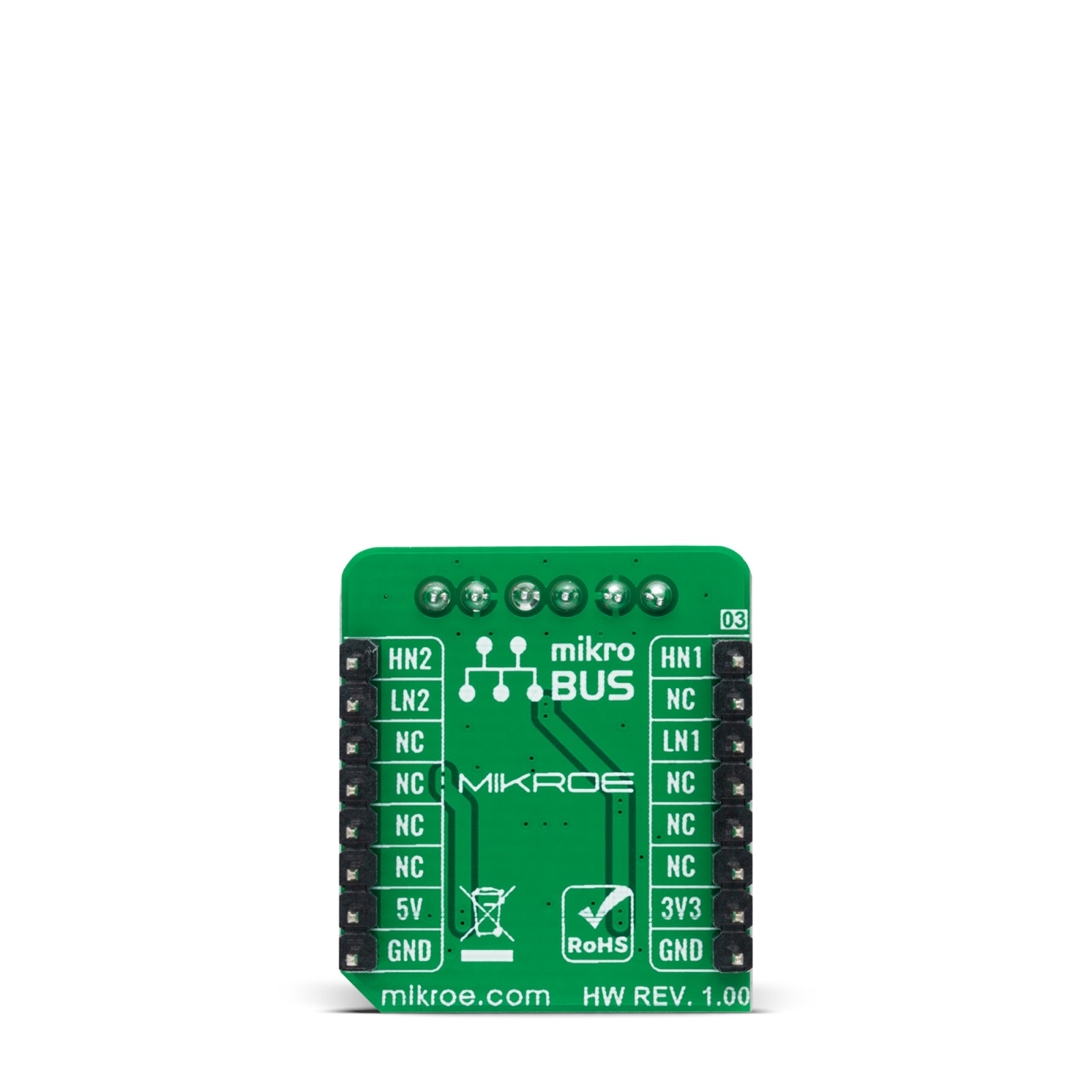

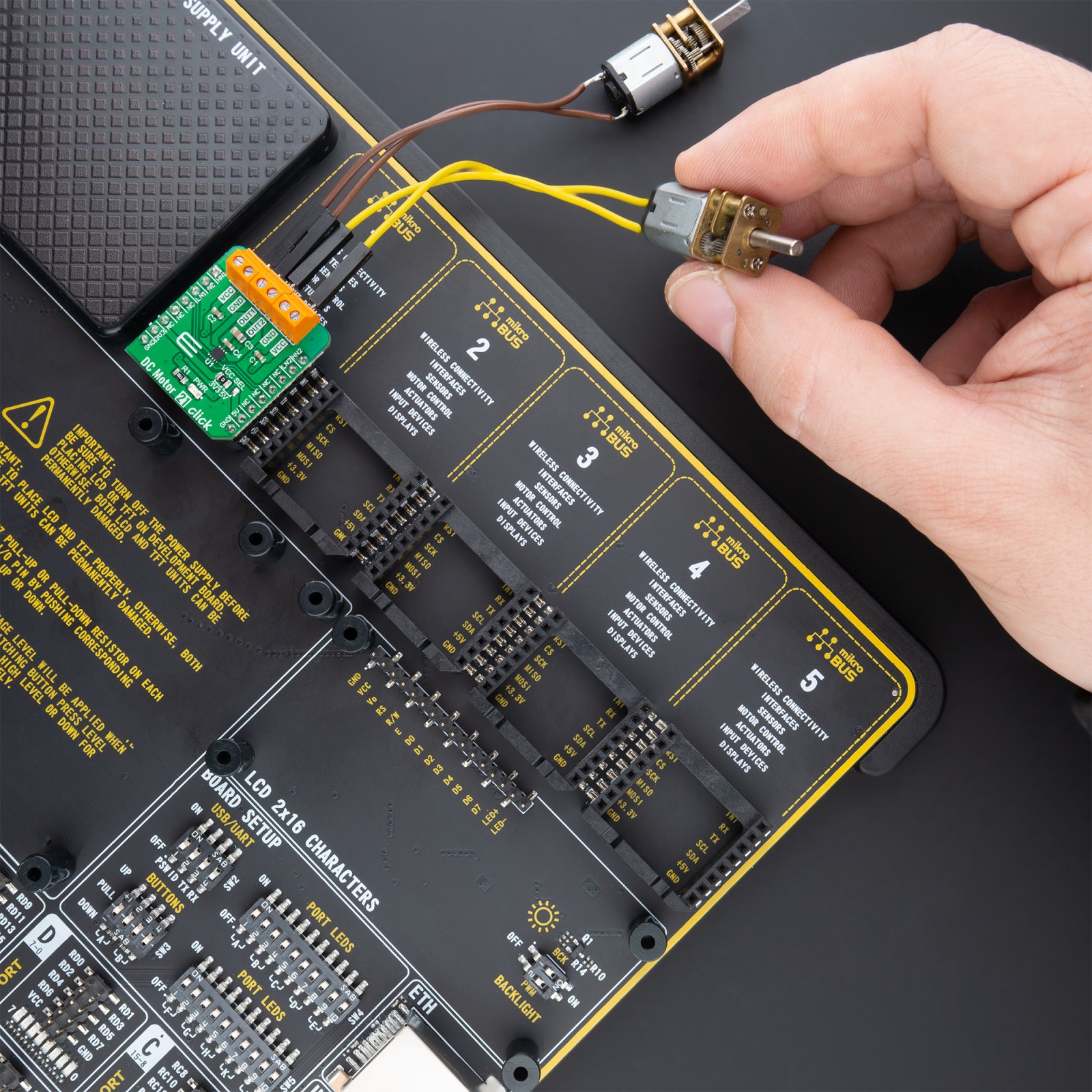

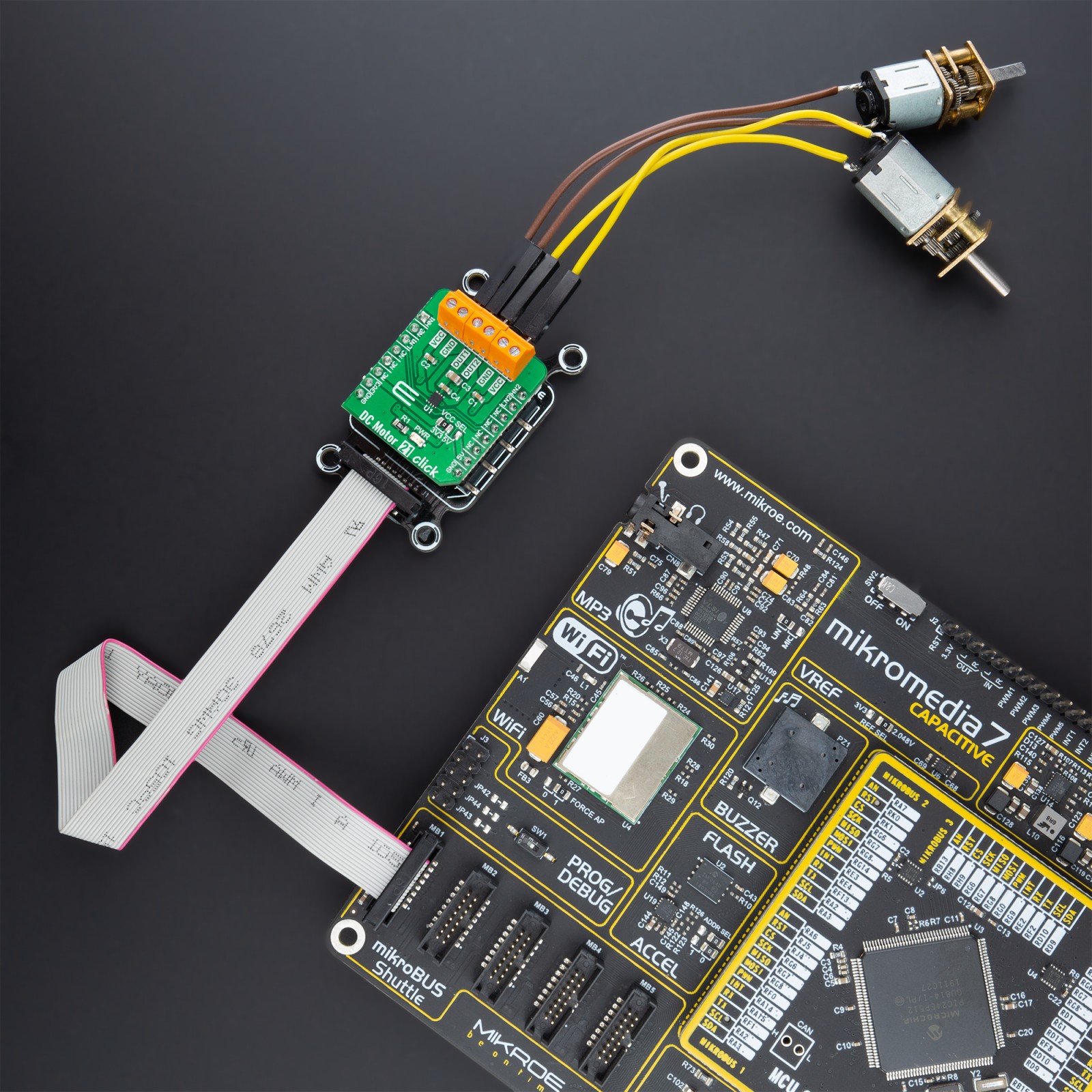

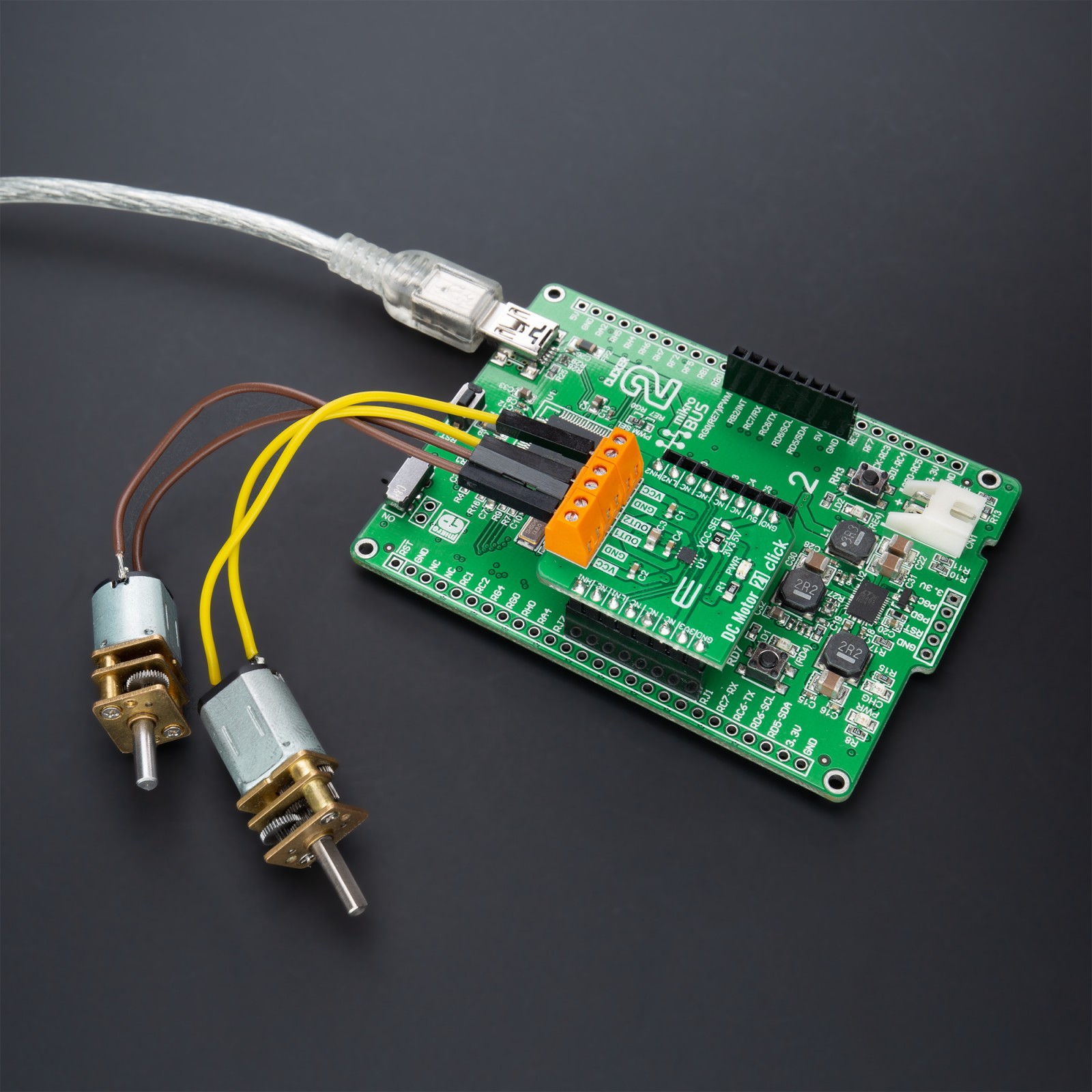

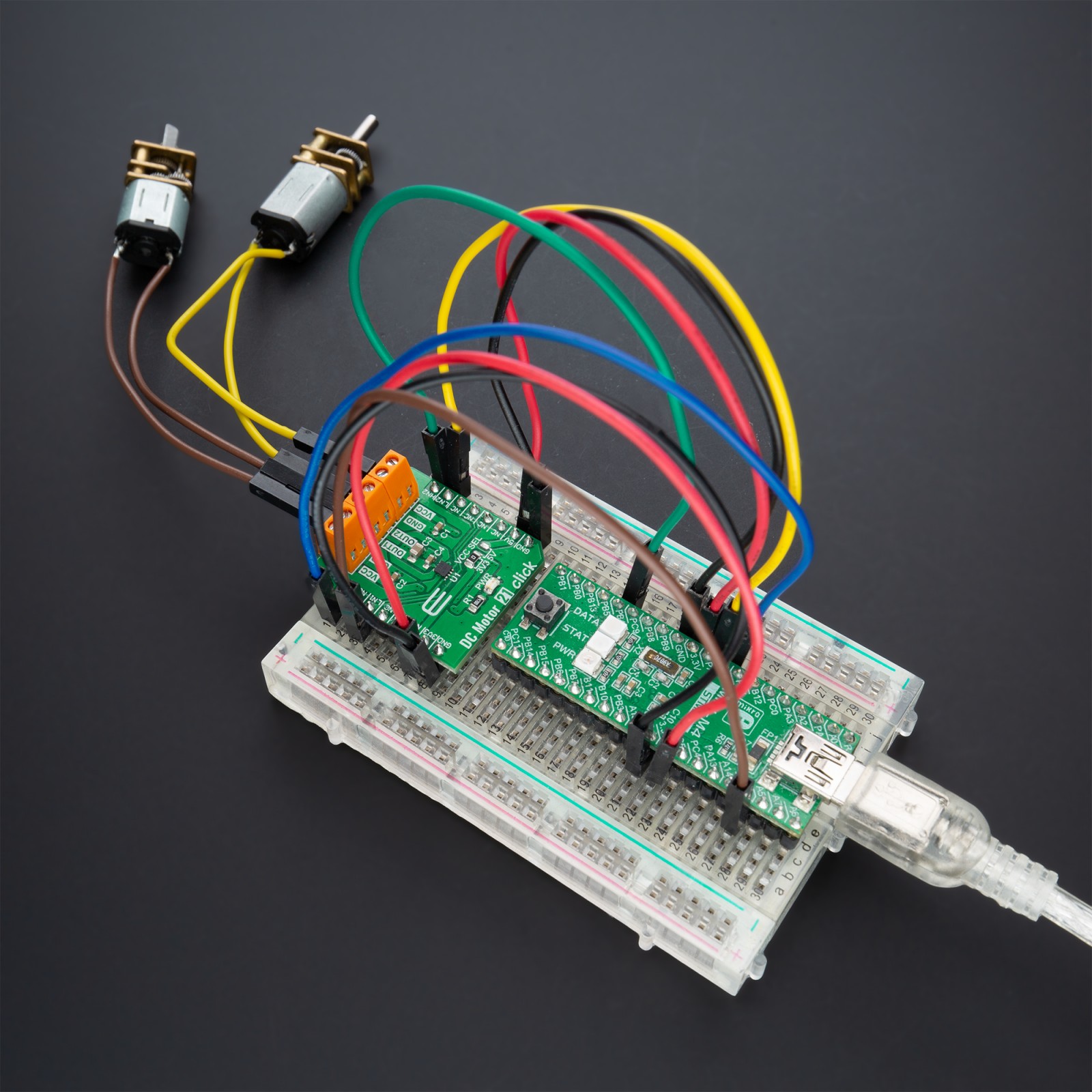

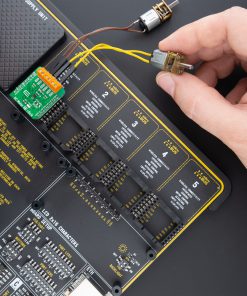

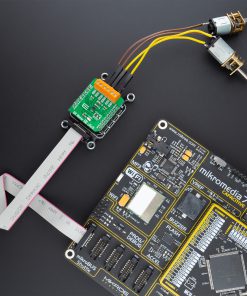

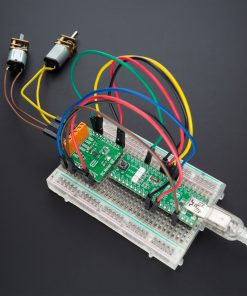

DC Motor 21 Click is a compact add-on board that contains a brushed DC motor driver. This board features the A3910, a DC motor driver designed for low voltage power applications from Allegro Microsystems. It is controlled via several GPIO pins and has a wide operating voltage range with an output current capacity of 500mA. In addition to the possibility to be used in the full-bridge configuration to drive a single bidirectional DC motor, it can also be used as a dual half-bridge to drive dual DC motors. Using an integrated MOS switch improves braking action for the motor, compared to implementation with a simple clamp diode. Besides, it also features built-in protection such as crossover current protection and thermal shutdown. This Click board™ is suitable for driving DC brushed motors and targeted at the consumer and industrial market with end applications to low voltage equipment.

DC Motor 21 Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R118.75 |

| 10+ | R112.50 |

| 15+ | R106.25 |

| 20+ | R102.25 |