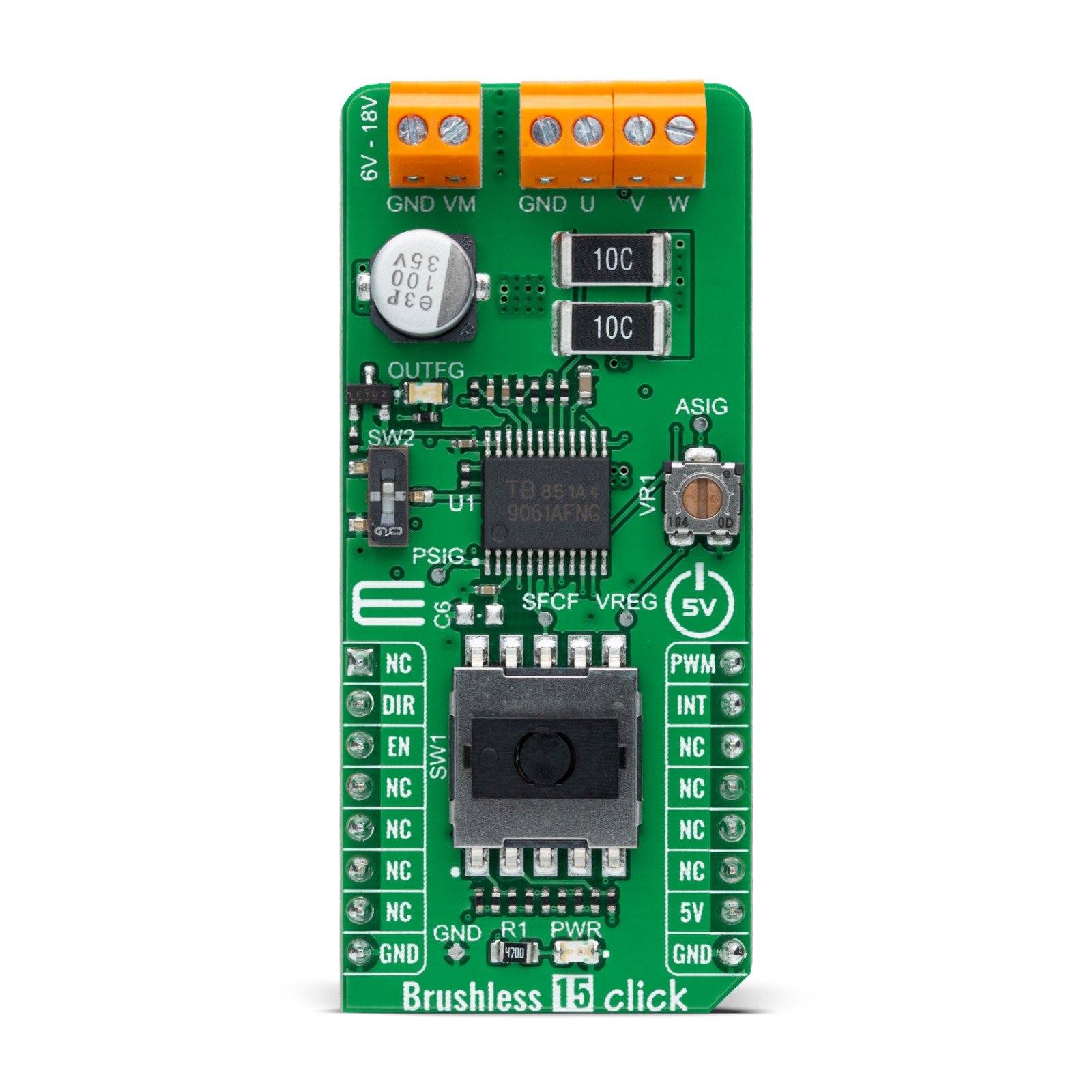

Brushless 15 Click

R665.00 ex. VAT

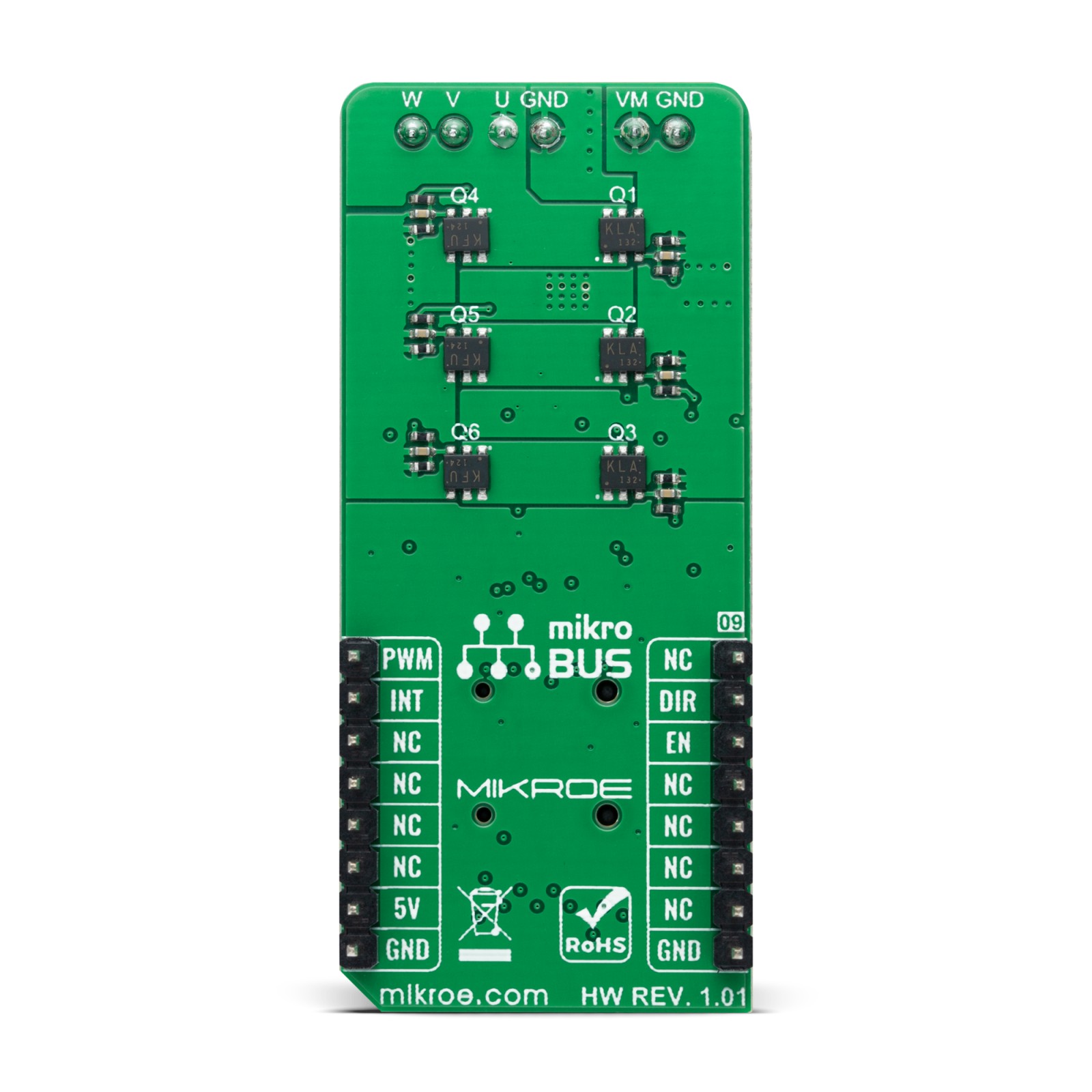

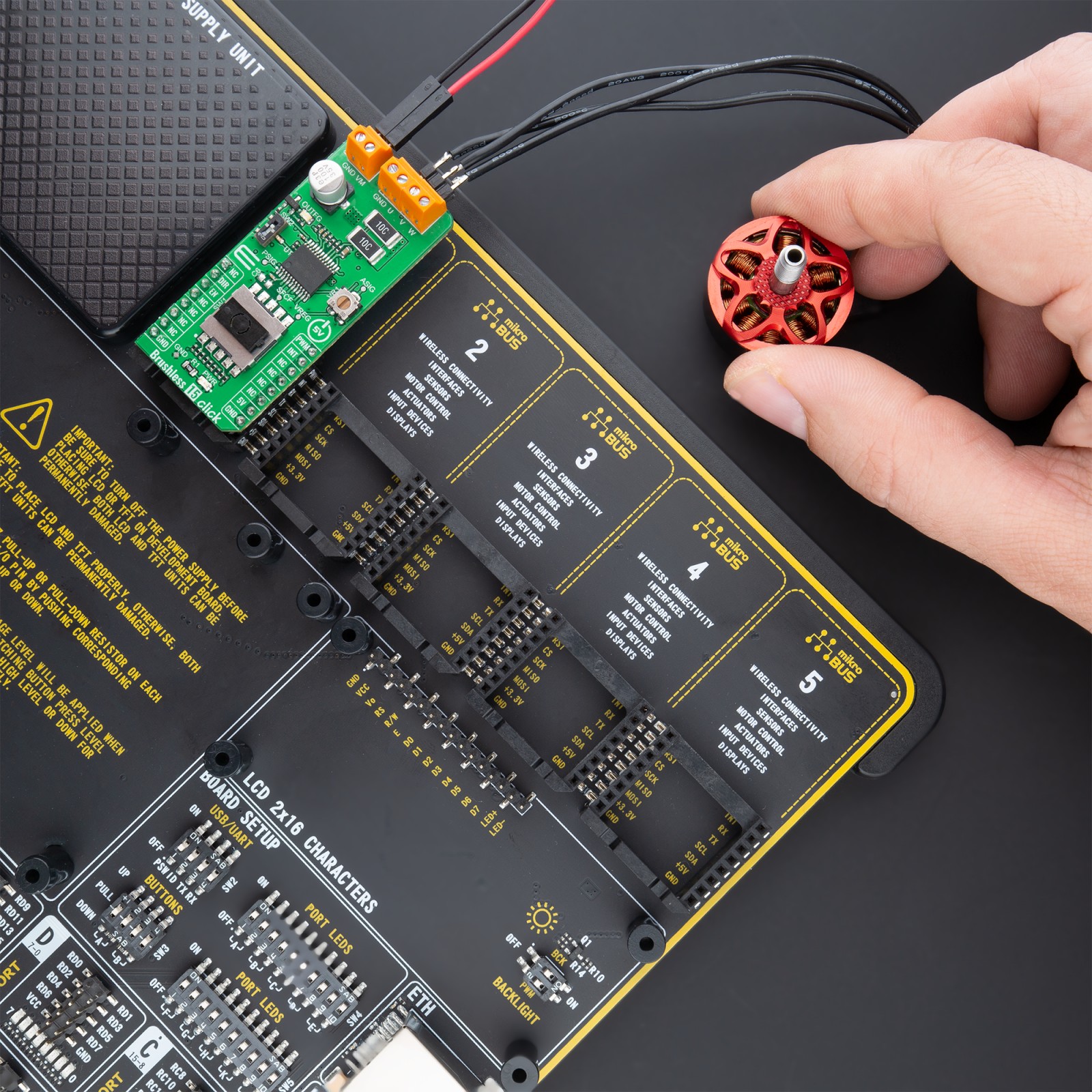

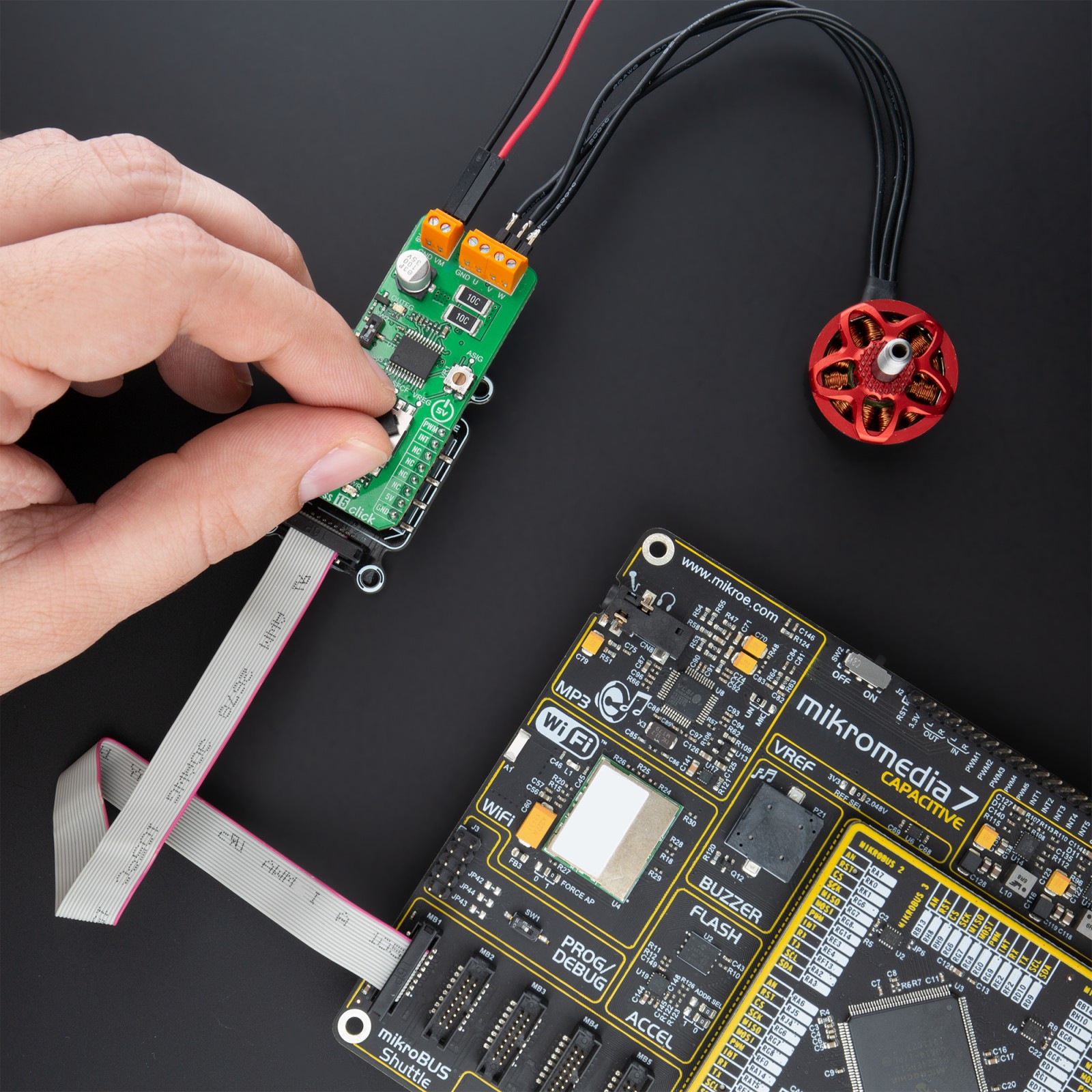

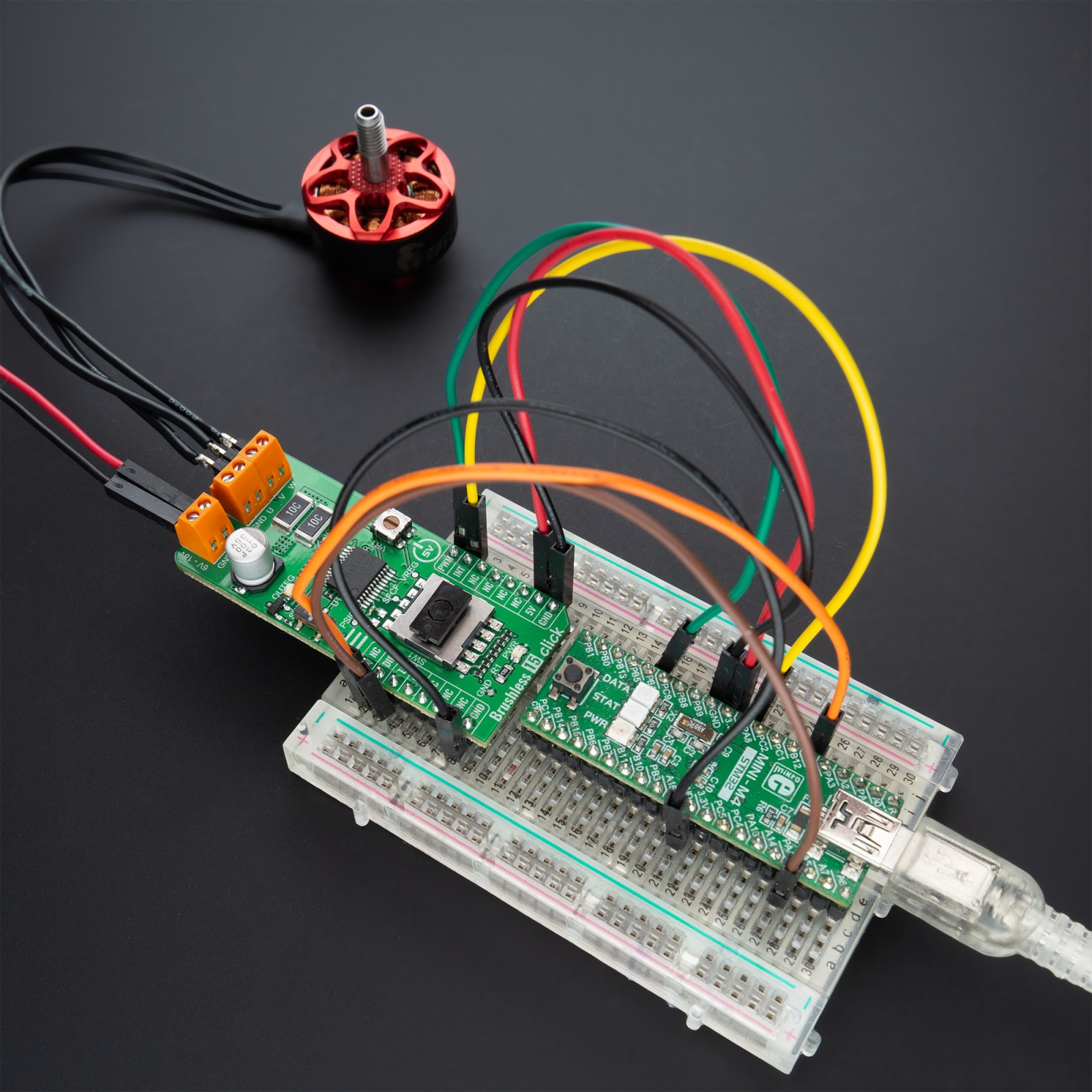

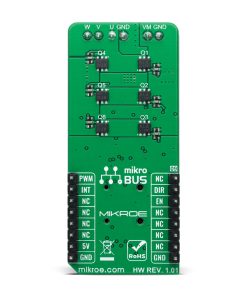

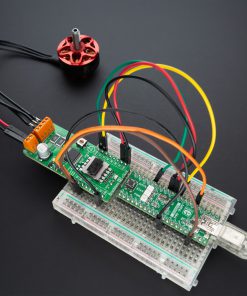

Brushless 15 Click is a compact add-on board suitable for controlling BLDC motors with any MCU. This board features the TB9061AFNG, an automotive pre-driver that incorporates a sensorless controller for driving a 3-phase full-wave brushless DC motor from Toshiba Semiconductor. The TB9061AFNG achieves 120° rectangular wave motor control by using an input signal line that measures the induced voltage of the motors and three-phase motor output without using Hall sensors, rated for an operating voltage range of 6 to 18V. Motor rotation can be controlled by either the DC or the PWM input signal. Besides, it features several diagnostic circuits and drive-control functions such as motor lock detection, step-out detection, over-current/over-temperature detection, and many more. This Click board™ can control motors without using heat-sensitive hole sensors, securing control of pumps in a hot environment providing optimum operating efficiency in automotive applications.

Brushless 15 Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R631.75 |

| 10+ | R598.50 |

| 15+ | R565.25 |

| 20+ | R543.97 |