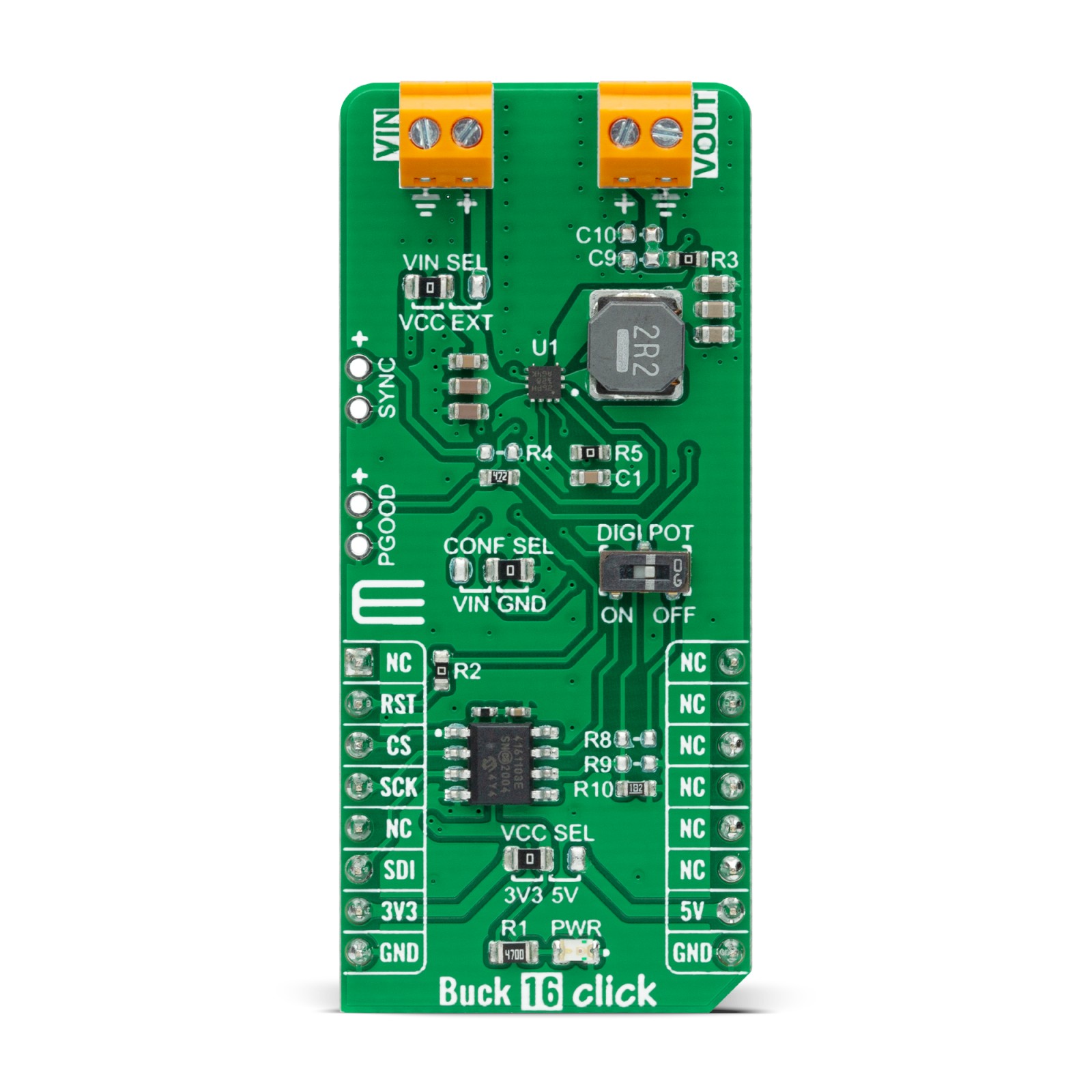

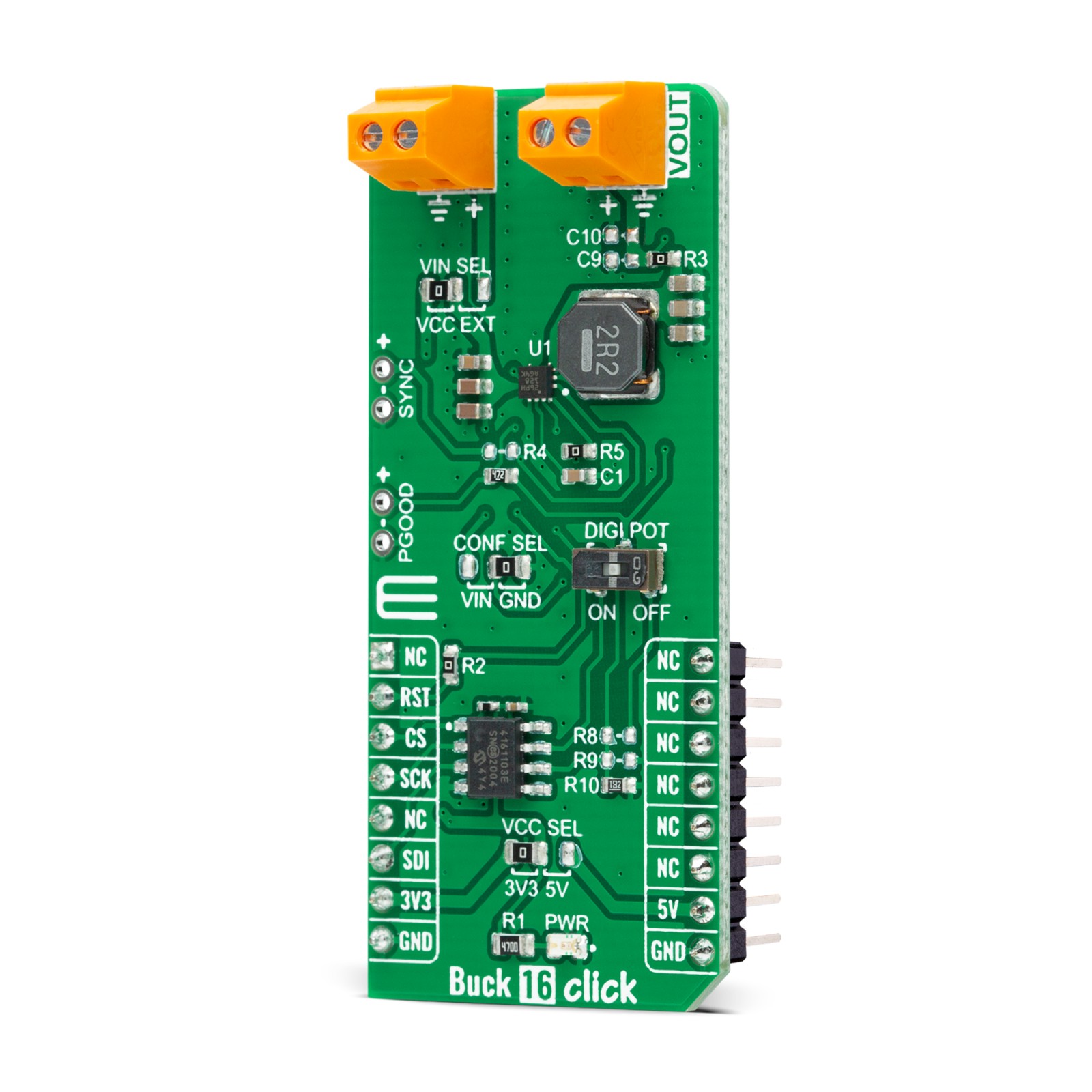

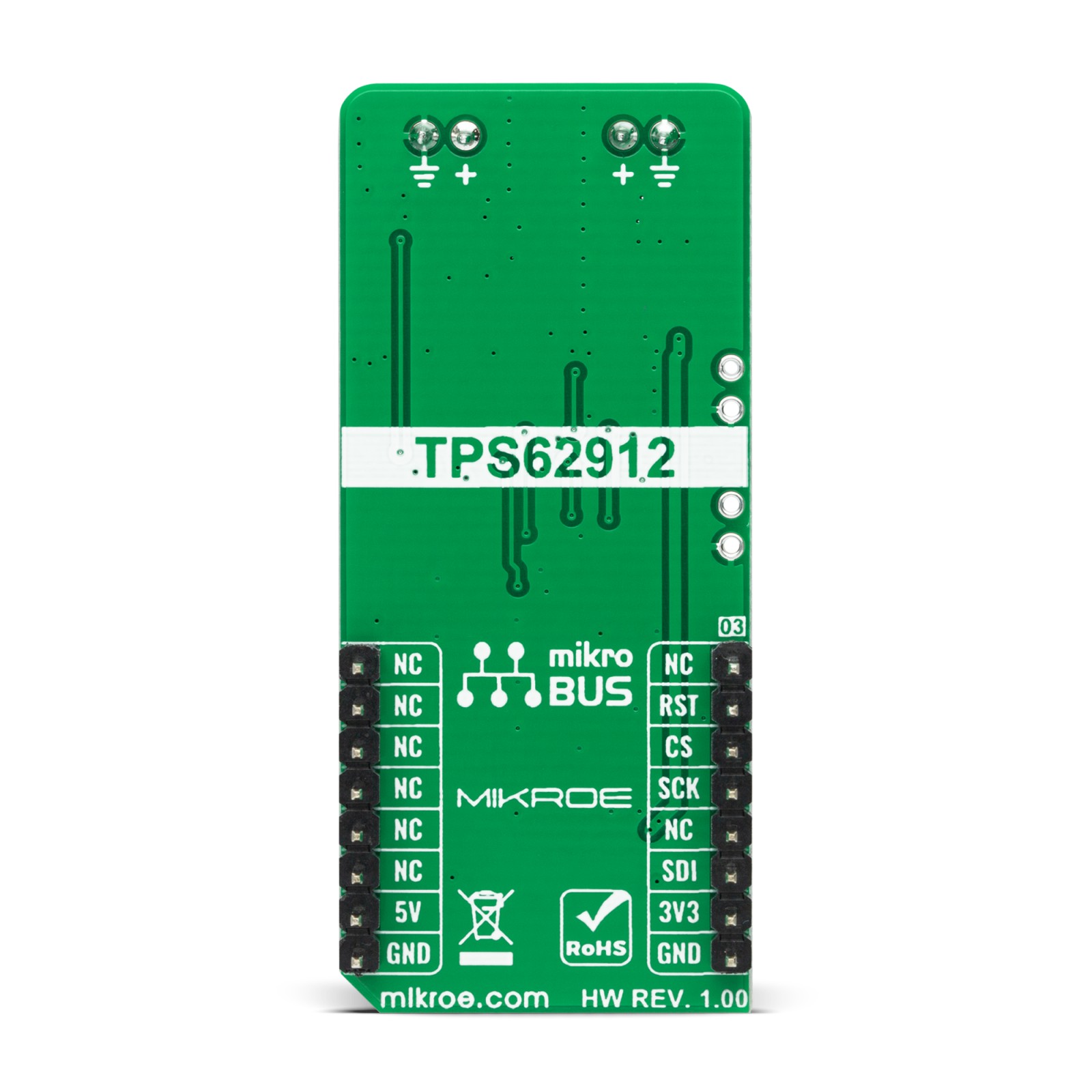

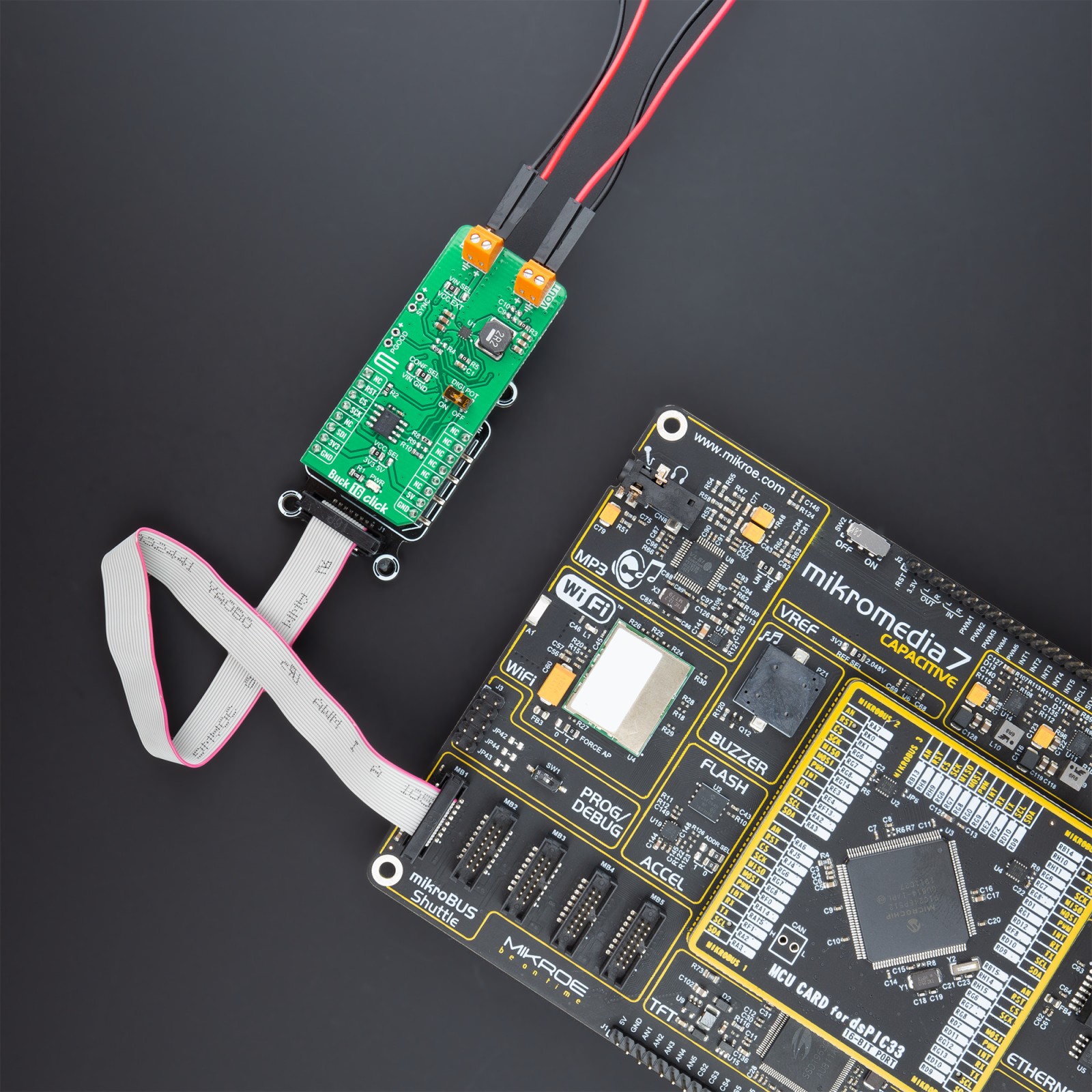

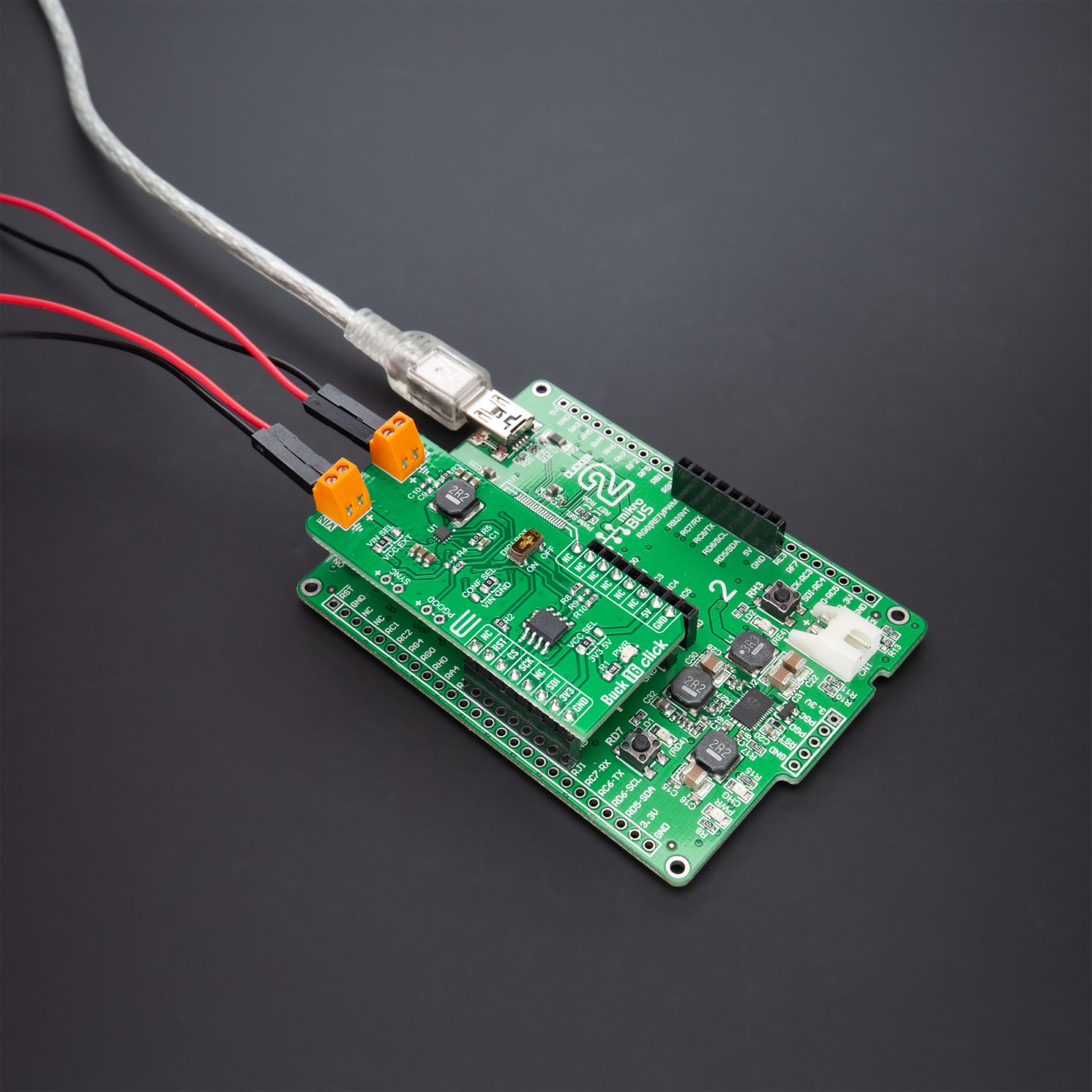

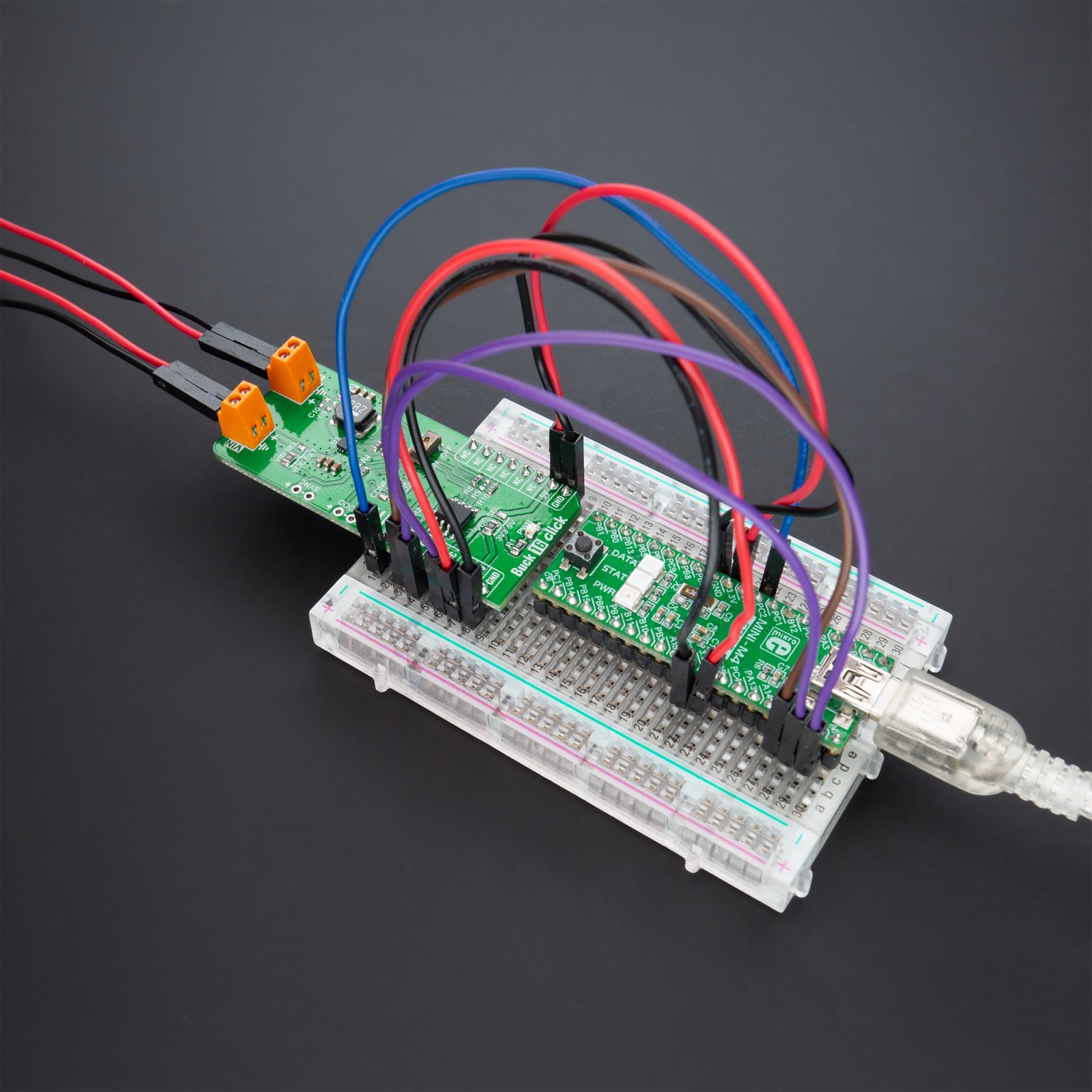

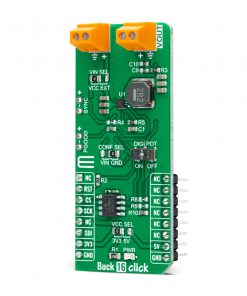

Buck 16 Click

R500.00 ex. VAT

Buck 16 Click is a compact add-on board that contains a DC-DC power converter that steps down the voltage from its input to its output. This board features the TPS62912, a high-efficiency, low noise, and low ripple current-mode synchronous buck converter from Texas Instruments. The TPS62912 has an output-voltage error of less than 1%, which helps ensure tight output-voltage accuracy, operates at a fixed switching frequency of 2.2MHz or 1MHz, and allows synchronization to an external clock. This Click board™ is suitable for noise-sensitive applications that generally use an LDO for post-regulation, such as high-speed ADCs, clock and jitter cleaner, serializer, de-serializer, and radar applications.

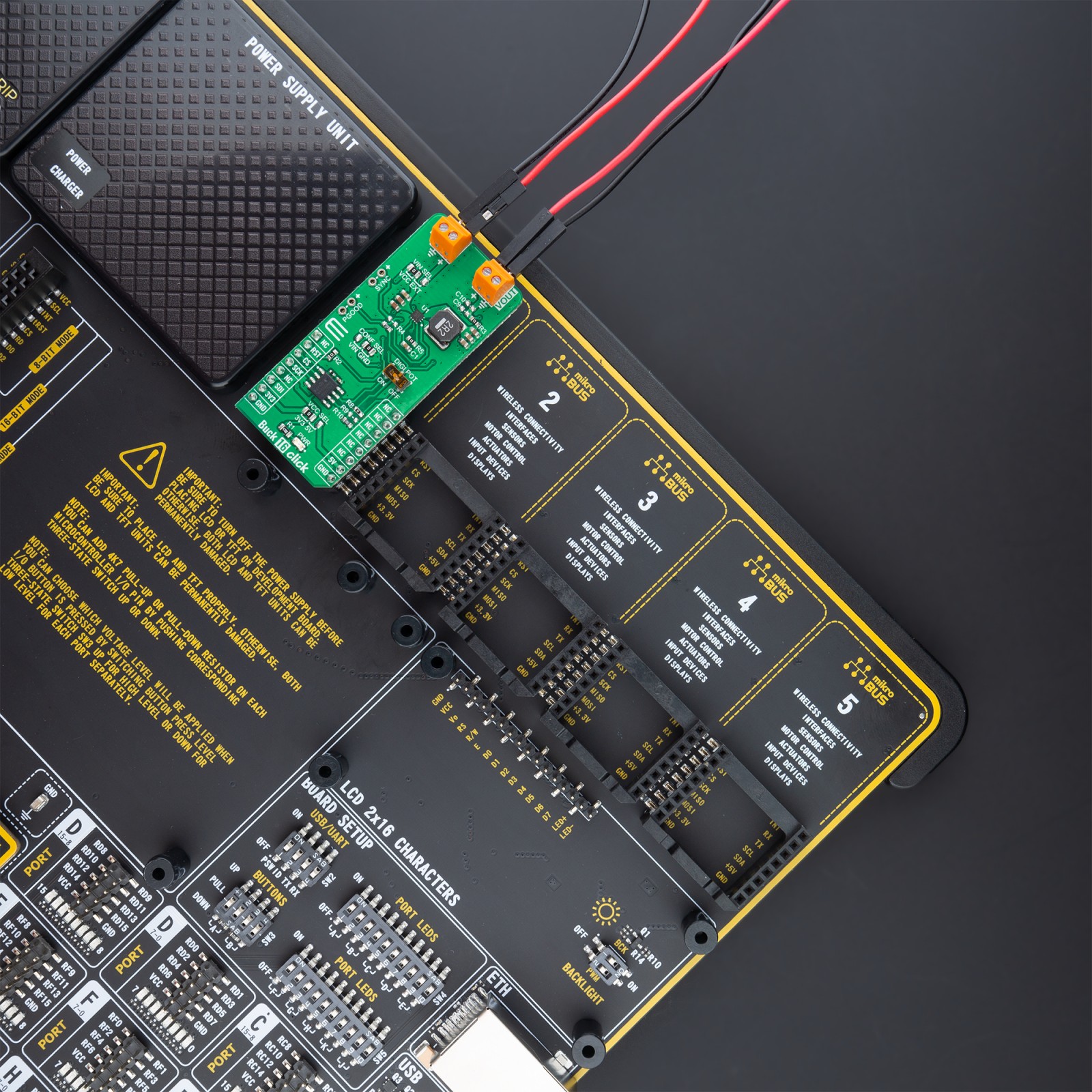

Buck 16 Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R475.00 |

| 10+ | R450.00 |

| 15+ | R425.00 |

| 20+ | R409.00 |