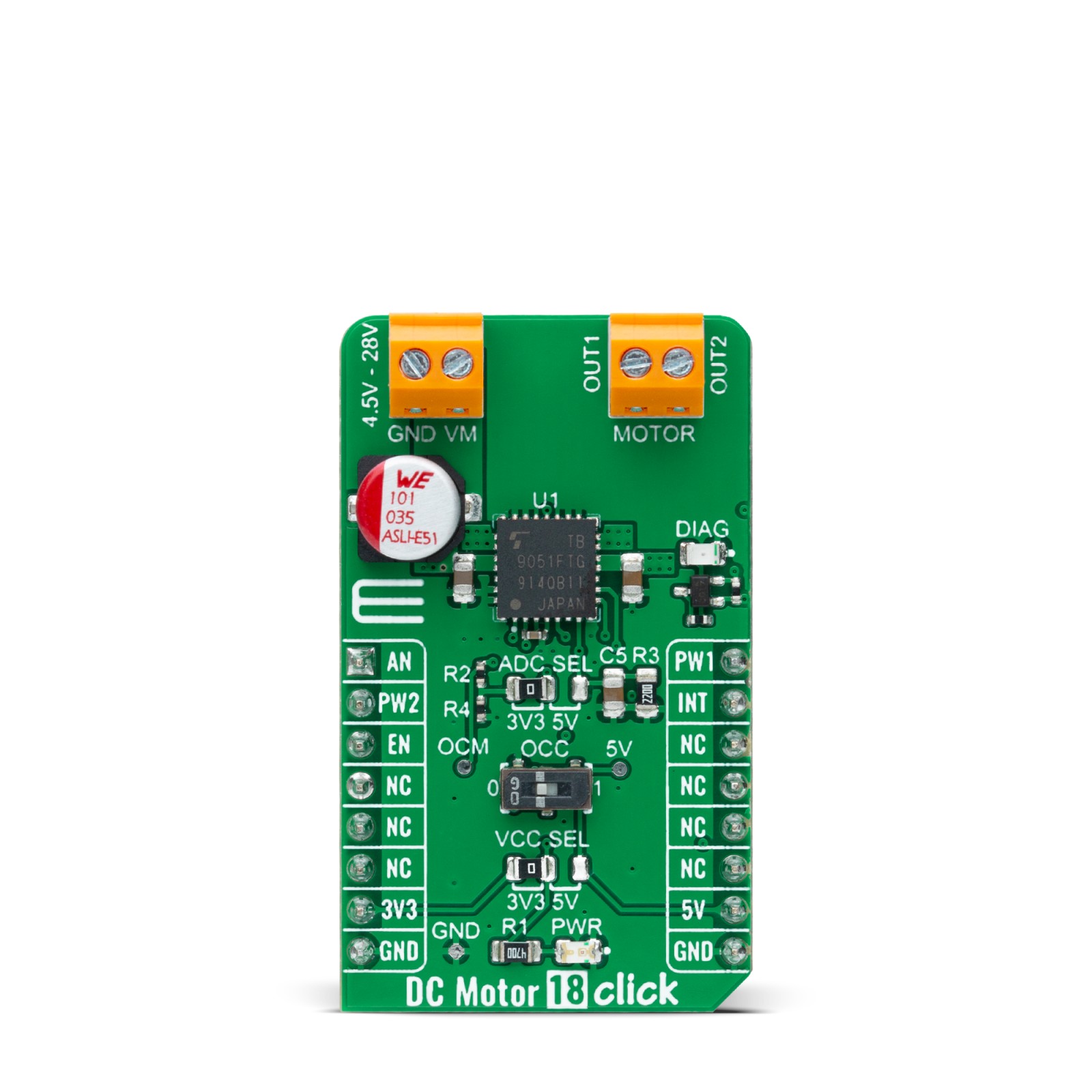

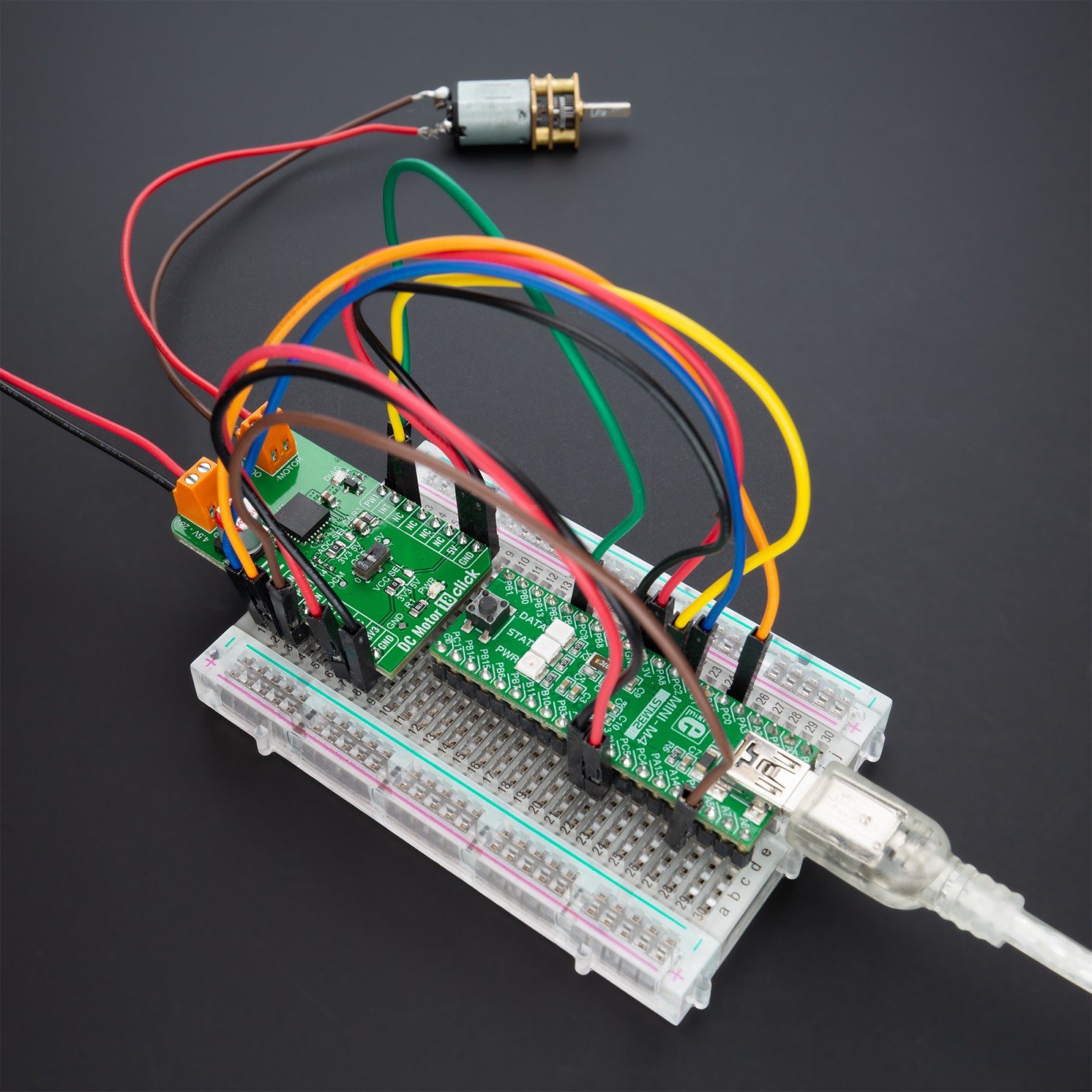

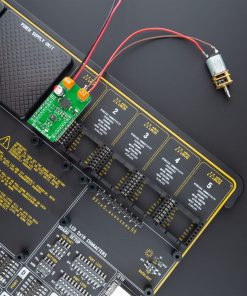

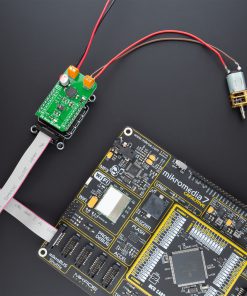

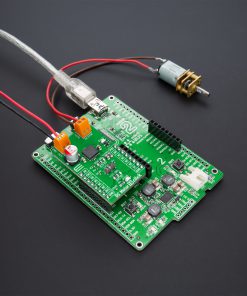

DC Motor 18 Click

R325.00 ex. VAT

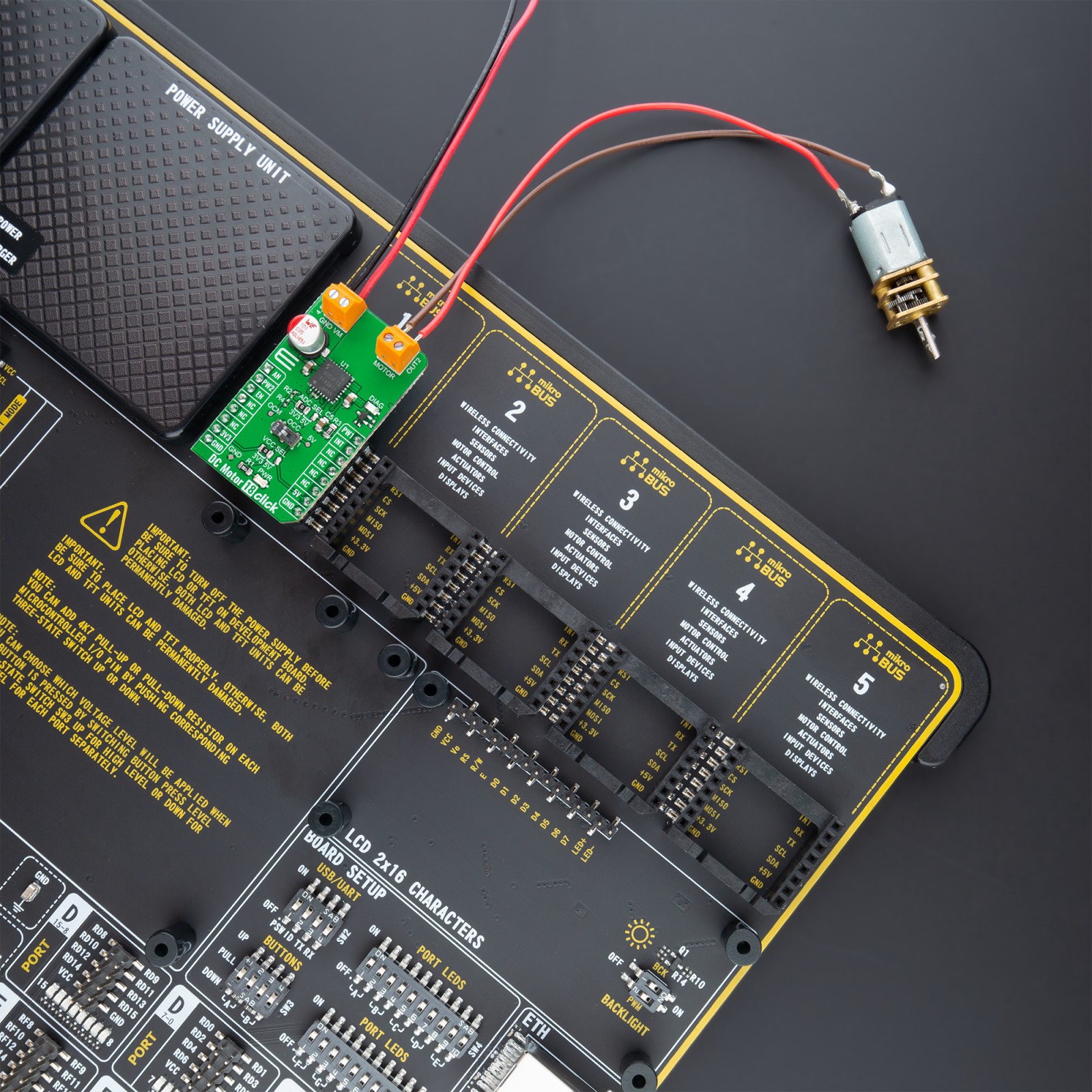

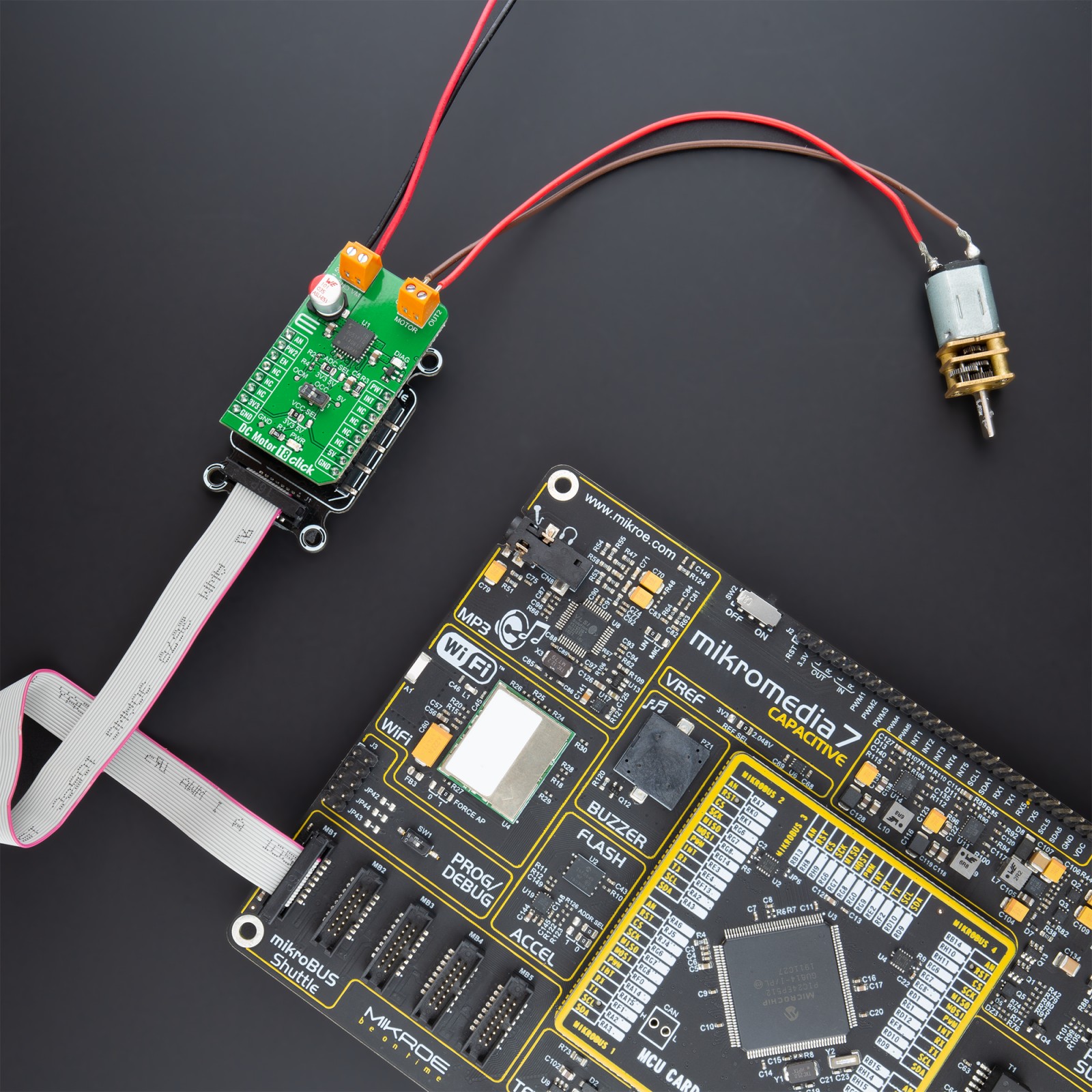

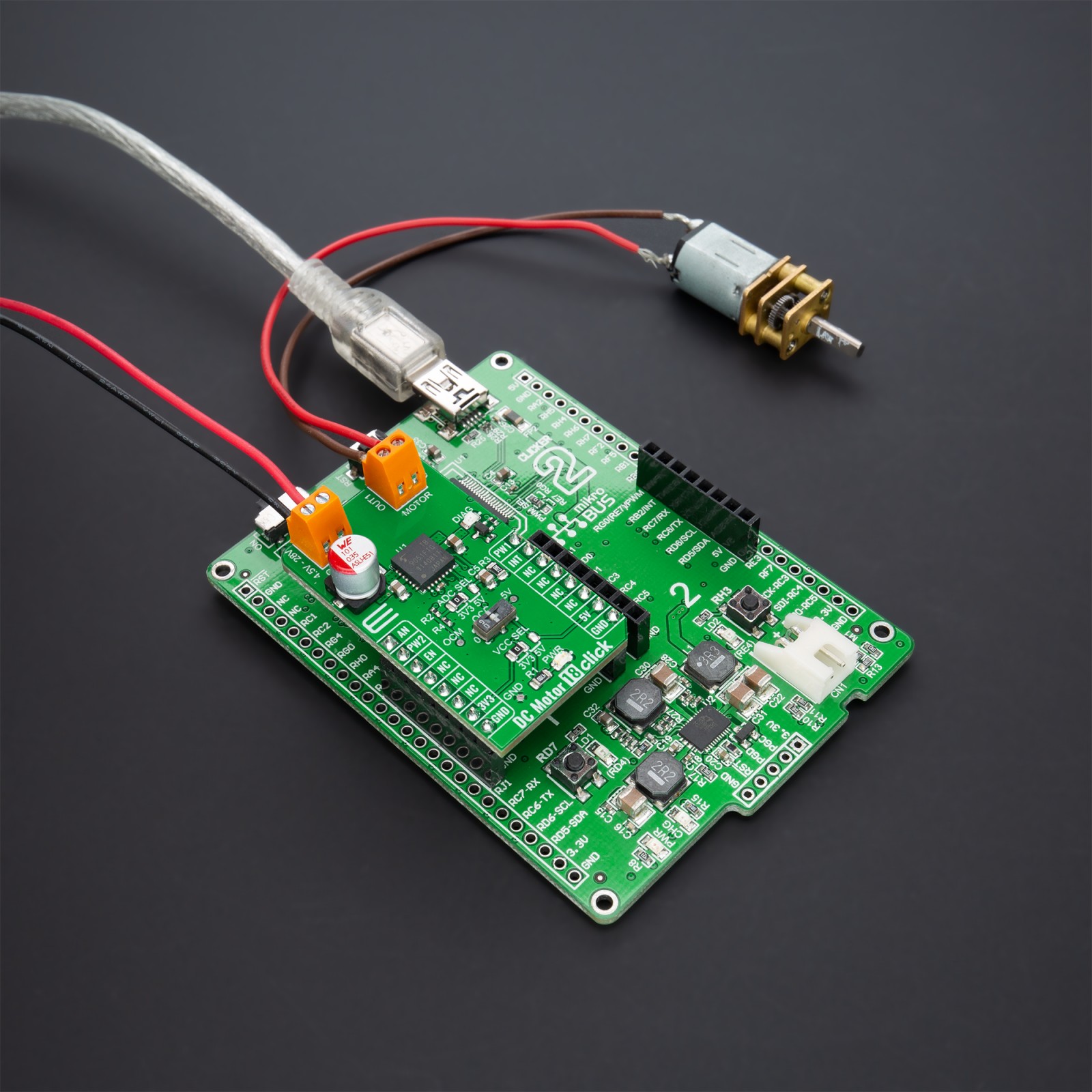

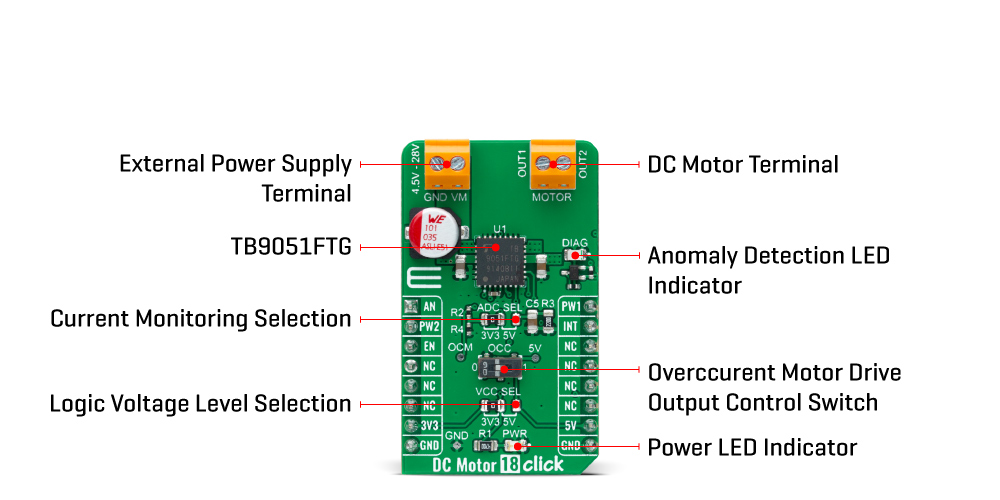

DC Motor 18 Click is a compact add-on board that contains a brushed DC motor driver. This board features the TB9051FTG, an automotive PWM-type single-channel H-Bridge DC brushed motor driver from Toshiba Semiconductor. The Forward/Reverse/Brake mode can be selected according to PWM control signals, while the motor operation and stop mode can be chosen by an enable pin. It has a wide operating voltage range of 4.5V to 28V with an output current capacity of 5A max. Besides, it also features built-in protection against under-voltage, overcurrent, and overtemperature conditions. This Click board™ is suitable for various automotive applications such as throttle and valve control, various engine bulbs, storing of door mirrors, and seat positioning.

DC Motor 18 Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R308.75 |

| 10+ | R292.50 |

| 15+ | R276.25 |

| 20+ | R265.85 |