Brushless 8 Click

R765.00 ex. VAT

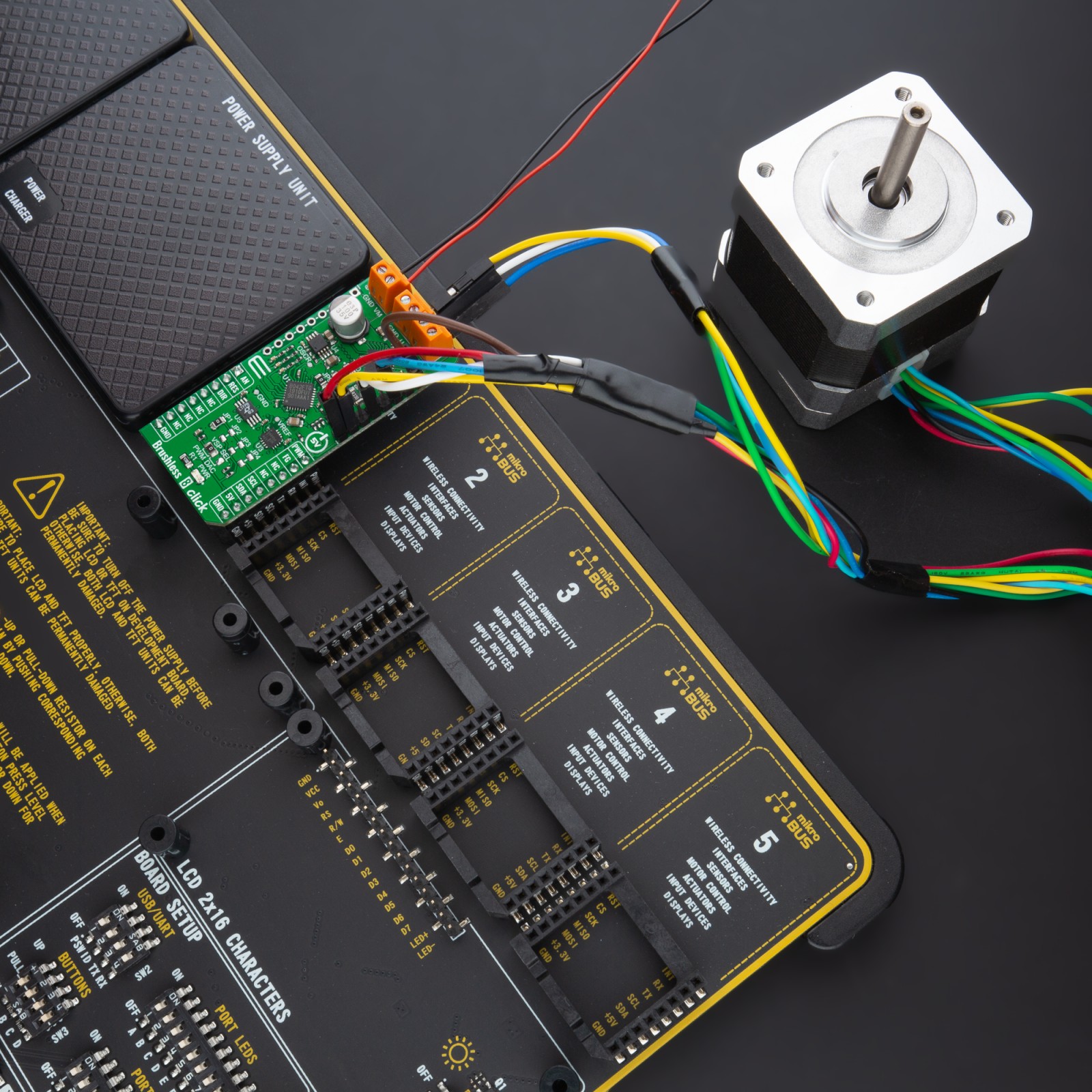

Brushless 8 Click is a compact add-on board suitable for controlling BLDC motors with any MCU. This board features the TC78B042FTG, a sine-wave PWM drive three-phase full-wave brushless motor controller from Toshiba Semiconductor. The TC78B042FTG has Toshiba’s original automatic phase adjustment function, which secures both a high-efficiency fan motor drive and sine-wave drive that reduces noise at a wide range of motor rotation speeds, from almost 0rpm (rotations per minute) at Start-Up up to several thousand rpm. This Click board™ makes the perfect solution for use in home appliances such as air-conditioner fans, air purifiers, and industrial equipment.

Brushless 8 Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R726.75 |

| 10+ | R688.50 |

| 15+ | R650.25 |

| 20+ | R625.77 |

How does it work?

Brushless 8 Click is based on the TC78B042FTG, a three-phase brushless motor controller that offers high efficiency over a wide rotation range with automatic phase adjustment from Toshiba Semiconductor. This motor controller incorporates Toshiba’s original developed Intelligent Phase Control that secures high-level efficiency for a wide range of rotation speeds. As a result, the new devices can be used with motor drivers that have various voltages and current capacities as well as being used in combination with intelligent power devices at the output stages. It uses a sine-wave drive system with a smooth current waveform that reduces noise and generates less noise and vibration than motors with a rectangular wave drive system.

.jpg)

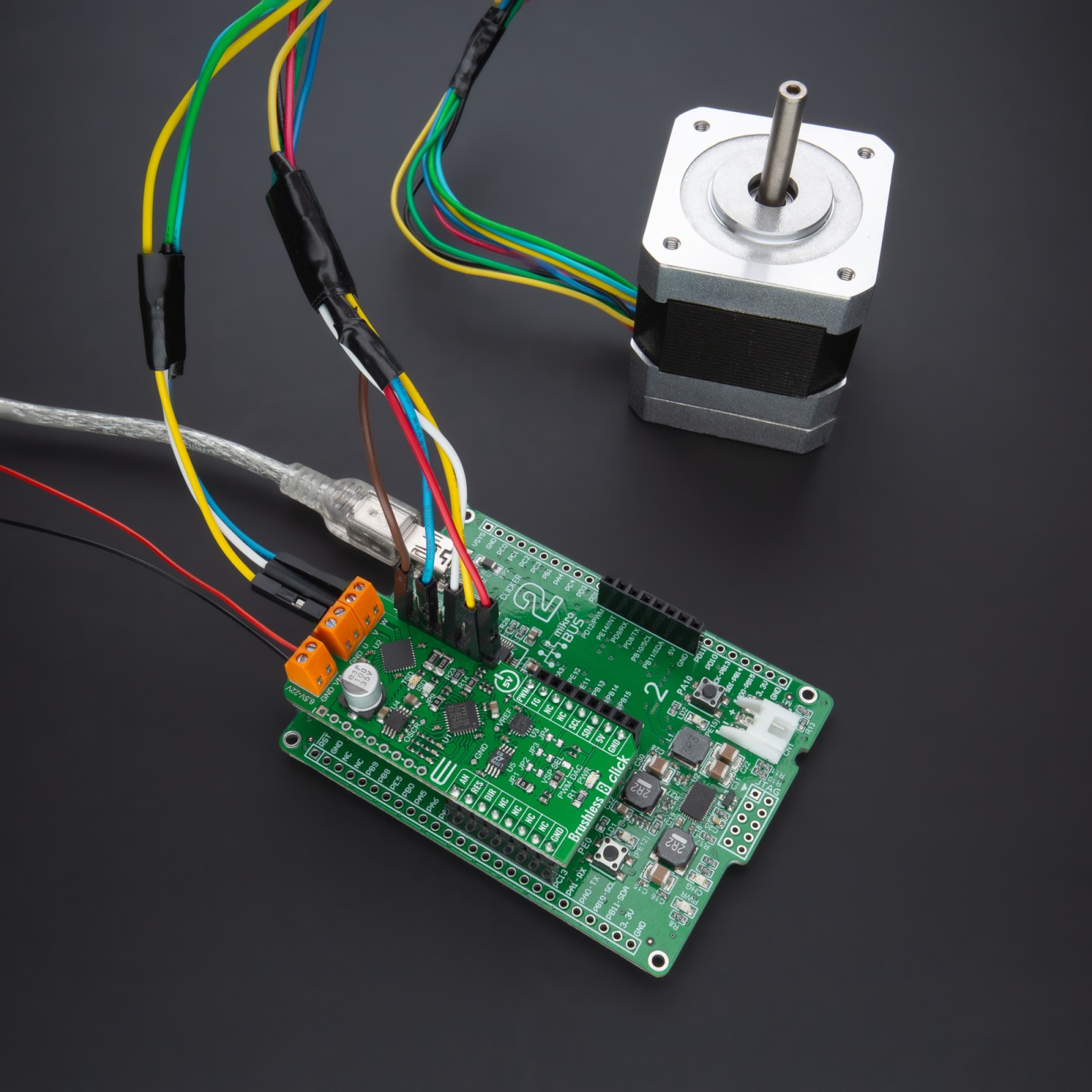

This Click board™ also contains a 3 channel Half-Bridge driver inverter, TB67Z800FTG from Toshiba Semiconductor, that receives its high and low side gate drive signals from TC78B042FTG and runs the connected Brushless DC Motor up to 22V/3A. For this type of application, more precisely for Brushless Click boards that require BLDC Motor with Hall Sensor for their work, Mikroe offers its users just one such motor, whose offer you can find here. The typical oscillation frequency is 9.22 MHz based on resistor R23 value 22kΩ drives the motor with 120° commutation. When the Hall signal indicates a rotation speed of 1 Hz or more, the motor rotates by estimating the rotor position according to the command of the LA pin. When rotation speed is less than 1Hz or the motor rotation direction is reversed, the motor is driven with 120° commutation.

The desired value on the previously mentioned LA pin as well as on other pins related to lead angle control, the TC78B042FTG obtains by the DAC3608, a low-power, eight-channel, digital-to-analog converter from Texas Instruments which establishes communication with MCU via I2C serial communication. Besides, the DAC43608 also allows the user to select a valid I2C address byte between 5V, GND, or I2C communication lines by positioning the jumper to an appropriate position marked from JP1 to JP4. As for the TC78B042FTG power supply, it is powered with a voltage value obtained by TPS7A49, an ultralow-noise linear regulator from Texas Instruments that converts an input value in the range of 6.5 to 22V to 6V that powers the main chip.

In addition to I2C communication, several GPIO pins connected to the mikroBUS™ socket pins are also used. The DIR pin, routed on the CS pin of the mikroBUS™ socket, is used to select the direction of motor rotation, while the control of the motor rotation speed itself can be chosen via the VSP SEL jumper. With this jumper, the user has the option of the rotation speed control using a PWM signal or using a value obtained by the DAC43608. The pin marked with RES routed at the RST pin of the mikroBUS™ socket can be used for Error detection more precisely for enabling or disabling commutation outputs. The FG pin at the INT pin of the mikroBUS™ socket represents the rotating pulse based on the selectable number of pulses per revolution. And the last pin labeled as AN provides accurate current monitoring via LT1999-10, a high-voltage, bidirectional current sense amplifier from Analog Devices.

There are also 2 headers on the board that contain both W, V, and U-phase Hall input signals, as well as a header with High & Low-side commutation signals. Besides, it has 2 LED indicators labeled as ISD and TSD intended for thermal shutdown and over-current protection.

This Click board™ is designed to be operated only with a 5V logic voltage level. A proper logic voltage level conversion should be performed before the Click board™ is used with MCUs with different logic levels.

Specifications

Type

Brushless

Applications

Can be used in home appliances such as air-conditioner fans, air purifiers, and industrial equipment.

On-board modules

Brushless 8 Click is based on the TC78B042FTG, a three-phase brushless motor controller that offers high efficiency over a wide rotation range without phase adjustment from Toshiba Semiconductor.

Key Features

Sine-wave PWM control, automatic lead angle control (InPAC), Hall sensor input, rotation switch, output current limit, built-in motor lock detection, and more.

Interface

Analog,GPIO,I2C,PWM

Feature

No ClickID

Compatibility

mikroBUS™

Click board size

L (57.15 x 25.4 mm)

Input Voltage

5V

Pinout diagram

This table shows how the pinout on Brushless 8 Click corresponds to the pinout on the mikroBUS™ socket (the latter shown in the two middle columns).

Onboard settings and indicators

| Label | Name | Default | Description |

|---|---|---|---|

| LD1 | PWR | – | Power LED Indicator |

| JP8 | VSP SEL | Left | Rotation Speed Control Selection PWM/DAC: Left position PWM, Right position DAC |

| JP1-JP4 | JP1-JP4 | JP1 Populated | DAC43608 Address Byte Selection |

| LD2 | TSD | – | TSD LED Indicator |

| LD3 | ISD | – | ISD LED Indicator |

| J1 | HALL | Populated | Hall Sensor Input Pins |

| J2 | – | Unpopulated | High & Low-Side Commutation Signals Pins |

Brushless 8 Click electrical specifications

| Description | Min | Typ | Max | Unit |

|---|---|---|---|---|

| Supply Voltage | 6.5 | – | 22 | V |

| Maximum Output Voltage | – | – | 18 | V |

| Maximum Output Current | – | – | 3 | A |

| Operating Frequency | 6.8 | 9.22 | 15.5 | MHz |

| Power Dissipation | – | – | 4.25 | W |

| Operating Temperature Range | -40 | – | +115 | °C |

Software Support

We provide a library for the Brushless 8 Click as well as a demo application (example), developed using MIKROE compilers. The demo can run on all the main MIKROE development boards.

Package can be downloaded/installed directly from NECTO Studio Package Manager (recommended), downloaded from our LibStock™ or found on MIKROE github account.

Library Description

This library contains API for Brushless 8 Click driver.

Key functions

-

brushless8_cfg_setupfunction initializes click configuration structure to initial values. -

brushless8_initfunction initializes all necessary pins and peripherals used for this click board. -

brushless8_default_cfgfunction executes a default configuration of Brushless 8 click board.

Example Description

This application is a schowcase of controlling speed and direction of brushless motor with hall sesnor.

void application_task ( void )

{

if ( BRUSHLESS8_PWM == brushless8.ctrl_mod )

{

for ( float duty = 0.1; duty < 1; duty += 0.1 )

{

Delay_ms ( COMM_DELAY );

brushless8_set_reset( &brushless8, BRUSHLESS8_RESET_DIS );

brushless8_set_duty_cycle( &brushless8, duty );

brushless8_set_reset( &brushless8, BRUSHLESS8_RESET_EN );

log_info( &logger, "Duty: %u%%", ( uint16_t )ceil( duty * 100 ) );

float adc_vout;

brushless8_read_an_voltage( &brushless8, &adc_vout );

log_info( &logger, "ADC [ V ]: %.2f", adc_vout );

log_printf( &logger, "------------------------------rn" );

}

for ( float duty = 0.9; duty >= 0; duty -= 0.1 )

{

Delay_ms ( COMM_DELAY );

brushless8_set_reset( &brushless8, BRUSHLESS8_RESET_DIS );

brushless8_set_duty_cycle( &brushless8, duty );

brushless8_set_reset( &brushless8, BRUSHLESS8_RESET_EN );

log_info( &logger, "Duty: %u%%", ( uint16_t )ceil( duty * 100 ) );

float adc_vout;

brushless8_read_an_voltage( &brushless8, &adc_vout );

log_info( &logger, "ADC [ V ]: %.2f", adc_vout );

log_printf( &logger, "------------------------------rn" );

}

Delay_ms ( COMM_DELAY );

brushless8_pwm_stop( &brushless8 );

Delay_ms ( COMM_DELAY );

brushless8_pwm_start( &brushless8 );

} else if ( BRUSHLESS8_DAC == brushless8.ctrl_mod ) {

for ( int16_t dsvp = 200; dsvp <= 5000; dsvp += ( ( 5000 - 200 ) / 10 ) )

{

Delay_ms ( COMM_DELAY );

brushless8_set_reset( &brushless8, BRUSHLESS8_RESET_EN );

brushless8_set_dac_vout( &brushless8, BRUSHLESS8_DAC_REG_CHN_A_DVSP, ( uint16_t )dsvp );

brushless8_set_reset( &brushless8, BRUSHLESS8_RESET_EN );

log_info( &logger, "DSVP [ mV ]: %d", dsvp );

float adc_vout;

brushless8_read_an_voltage( &brushless8, &adc_vout );

log_info( &logger, "ADC [ V ]: %.2f", adc_vout );

log_printf( &logger, "------------------------------rn" );

}

for ( int16_t dsvp = 5000; dsvp >= 200; dsvp -= ( ( 5000 - 200 ) / 10 ) )

{

Delay_ms ( COMM_DELAY );

brushless8_set_reset( &brushless8, BRUSHLESS8_RESET_EN );

brushless8_set_dac_vout( &brushless8, BRUSHLESS8_DAC_REG_CHN_A_DVSP, ( uint16_t )dsvp );

brushless8_set_reset( &brushless8, BRUSHLESS8_RESET_EN );

log_info( &logger, "DSVP [ mV ]: %d", dsvp );

float adc_vout;

brushless8_read_an_voltage( &brushless8, &adc_vout );

log_info( &logger, "ADC [ V ]: %.2f", adc_vout );

log_printf( &logger, "------------------------------rn" );

}

} else {

log_error( &logger, "Application Task Error" );

log_info( &logger, "Please, run program again..." );

for ( ; ; );

}

}

The full application code, and ready to use projects can be installed directly from NECTO Studio Package Manager (recommended), downloaded from our LibStock™ or found on MIKROE github account.

Other MIKROE Libraries used in the example:

- MikroSDK.Board

- MikroSDK.Log

- Click.Brushless8

Additional notes and informations

Depending on the development board you are using, you may need USB UART click, USB UART 2 Click or RS232 Click to connect to your PC, for development systems with no UART to USB interface available on the board. UART terminal is available in all MIKROE compilers.

mikroSDK

This Click board™ is supported with mikroSDK – MIKROE Software Development Kit. To ensure proper operation of mikroSDK compliant Click board™ demo applications, mikroSDK should be downloaded from the LibStock and installed for the compiler you are using.

For more information about mikroSDK, visit the official page.

Resources

Downloads

| Weight | 22 g |

|---|---|

| Brand | MikroElektronika |